Pump bearing cooler

A technology for cooling devices and pump bearings, which is applied to components of pumping devices for elastic fluids, pump elements, variable displacement pump components, etc., and can solve the problem of lack of cooling devices, short cold water circulation time, and unsatisfactory cooling effects And other problems, to avoid heat loss, improve the effect of cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

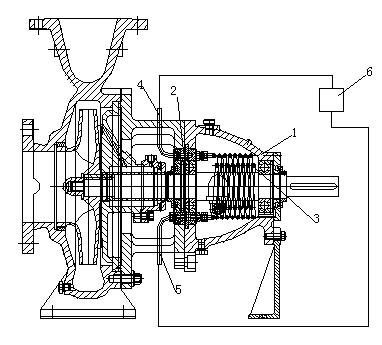

[0010] The present invention is arranged in the space formed by the suspension body 1 and the bearing seat 2 which are arranged in a split form, and is in the form of a spiral tube 3 , and its inlet 4 and outlet 5 both protrude from the bearing seat 2 .

[0011] The spiral pipe 3 is a double-layer sleeve type, the inner layer is water-through, and the outer layer is ventilated.

[0012] The pump is externally provided with a cooling device 6 arranged between the inlet 4 and the outlet 5 .

[0013] The inner layer of the spiral tube 3 of the present invention passes cold water, and the outer layer passes cold air to realize double-layer cooling, and the cooling effect is very good.

[0014] The present invention is equipped with a cooling device arranged between the inlet 4 and the outlet 5 outside the pump. The heat absorbed by the cooling water after passing through the pump bearing can pass through the heat exchange with the cooling device 6, so that the water can be circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com