A mechanized point-and-pillar room-and-pillar mining method

A mining method and point-and-pillar technology, which are applied in the field of mechanized point-and-pillar room-and-pillar mining, can solve the problems of poor economic benefits, high loss and dilution, and increased ore dilution, and achieve lower production costs, less operation disturbance, and less loss. The effect of dilution control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

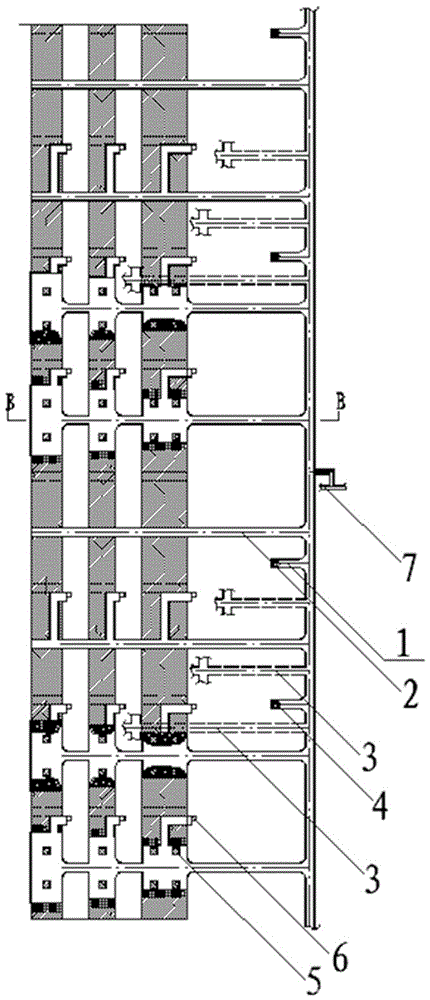

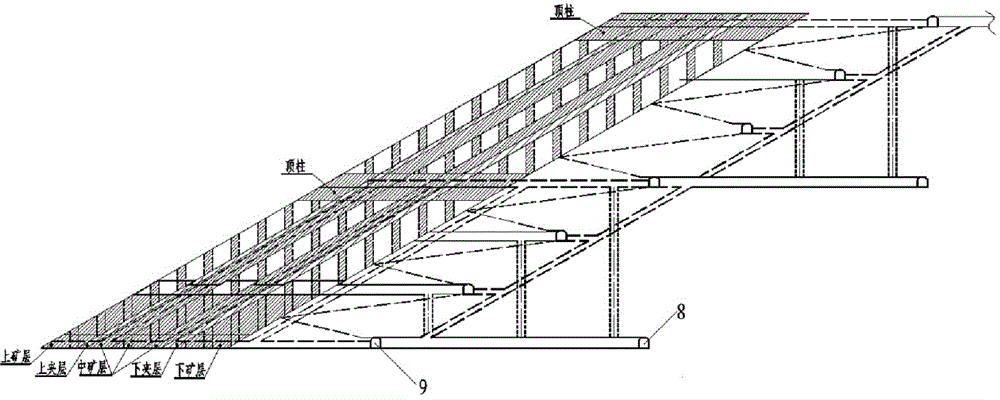

[0034]The panel area is arranged along the strike. The length of the panel area along the strike is 180m, and the oblique length of the inclination is controlled by the segmental height of 18m. The panel area is divided into 4 stopes according to the strike length of 45m. Columns are reserved along the inclination between the stopes and the panel intervals. The width of the inter-pillars is 3-4m. According to the stability of the roof, regular point columns and 8m top columns are left in the stope; multi-layer ore bodies can be mined at the same time to ensure that the inter-pillars and point columns of the upper and lower ore bodies are aligned vertically; The layout of the outer footwall is standard; the footwall of the lower ore body is arranged along the direction of the segmented roadway along the vein, and the ore-piercing and out-of-the-vein joint road is set up to facilitate the scraper to enter the layered mining face; the outer vein is arranged in the middle of the pan...

Embodiment 2

[0036] As in Example 1, in the first step, the panel area is arranged along the strike, and the length of the panel area along the strike is 220m, and the oblique length of the inclination is controlled according to the segmental height of 22m, and the panel area is divided into 4 stopes according to the strike length of 55m; Spacing columns are reserved along the inclination between the intervals and panel intervals, and the width of the interstitial columns is 3-4m. In the stope, regular point columns are reserved according to the stability of the roof, and 12m top columns are reserved at the same time; multi-layer ore bodies can be mined at the same time to ensure that the upper and lower ore bodies Align vertically with the point column; adopt the standard layout of the footwall outside the vein; arrange segmental roadways along the vein along the strike of the footwall of the lower ore body, and set up the vein-crossing and out-of-mine joint road, which is convenient for th...

Embodiment 3

[0038] In the first step, the panel area is 200m long along the strike, and the oblique length of the dip is controlled according to the segmental height of 20m. The panel area is divided into 4 stopes according to the strike length of 50m; The width is 3~4m. According to the stability of the roof, regular point pillars and 10m top pillars are left in the stope; in the third step, return air is arranged on the footwall of the segmented roadway along the trend of the ore body every 500m; The cycle of rock formation, ore extraction and stratified filling is 30 days. The mining operation is carried out by the first stratified cutting and level entry, and the stratified mining height is 5.0m. φ56mm. All the other steps are as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com