Method for manufacturing high-temperature-resisting black borosilicate glass

A technology of borosilicate glass and high temperature resistance, which is applied in the field of high temperature resistant black borosilicate glass prepared by magnetron sputtering technology, which can solve the problems of no particularly mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

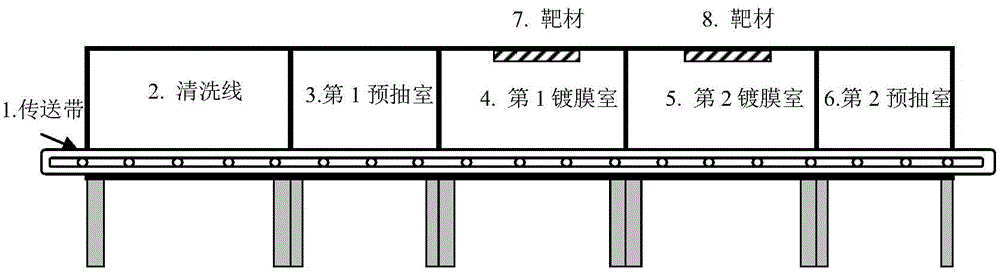

[0027] The invention provides a continuous sputtering coating equipment, the structure of the continuous sputtering coating equipment is as follows figure 1 As shown, it includes a conveyor belt 1 and four vacuum chambers, and the four vacuum chambers include a first pre-pumping chamber 3 , a first coating chamber 4 , a second coating chamber 5 and a second pre-pumping chamber 6 . The first pre-extraction chamber 3 is located in front of the first coating chamber 4, the first coating chamber 4 is adjacent to the second coating chamber 5, the second pre-extraction chamber 6 is located behind the second coating chamber 5, and the conveyor belt is in the first pre-extraction chamber. chamber, at least two coating chambers, and the second pre-pumping chamber are cyclically rotated to transport the borosilicate glass to be coated. In addition, a glass cleaning line 2 is provided for cleaning and air-drying the borosilicate glass to be coated. The glass cleaning line 2 is integrated...

Embodiment 2

[0050] Embodiment 2 provides a kind of continuous sputtering coating equipment, described continuous sputtering coating equipment except including all structures of embodiment 1, also comprises the 3rd coating room, the 3rd coating room is located in the second coating room 5 and the second Between 6 pre-pumping chambers.

[0051] Correspondingly, in the method for preparing high-temperature-resistant black borosilicate glass in Example 2, the borosilicate glass to be coated enters the third coating chamber for further coating treatment after the coating treatment in the second coating chamber 5, and then enters The second pre-pumping chamber 6. In Example 2, one of the TiAlN film or the silicon nitride film is respectively deposited in the first coating chamber to the third coating chamber. Silicon oxide thin film; method two: the first and second coating chambers deposit TiAlN thin films, and the third coating chamber deposits silicon nitride thin films; method three: the f...

Embodiment 3

[0053] Embodiment 3 provides a kind of continuous sputtering coating equipment, described continuous sputtering coating equipment except including all structures of embodiment 1, also comprises at least the 3rd coating room and the 4th coating room, at least the 3rd coating room and the 4th coating room The four coating chambers are located between the second coating chamber 5 and the second pre-pumping chamber 6 .

[0054] Correspondingly, in the method for preparing high-temperature-resistant black borosilicate glass in Example 3, the borosilicate glass to be coated enters at least the third coating chamber and the fourth coating chamber for further processing after the coating treatment in the second coating chamber 5. Coating treatment, and then enter the second pre-pumping chamber 6. In embodiment 3, each coating chamber deposits one of TiAlN film or silicon nitride film respectively. ...the coating chambers all deposit silicon nitride films; method 2: the first and seco...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap