Hub casting system

A pouring system and hub technology, applied in casting molding equipment, molds, cores, etc., can solve problems such as shrinkage holes/loose defects, and achieve the effect of ensuring integrity, overcoming pouring defects, and eliminating pouring defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

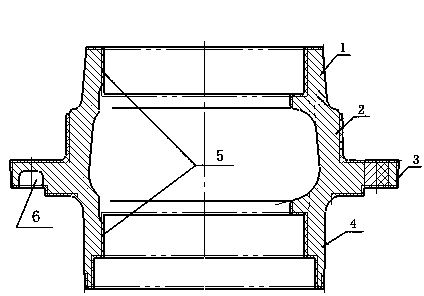

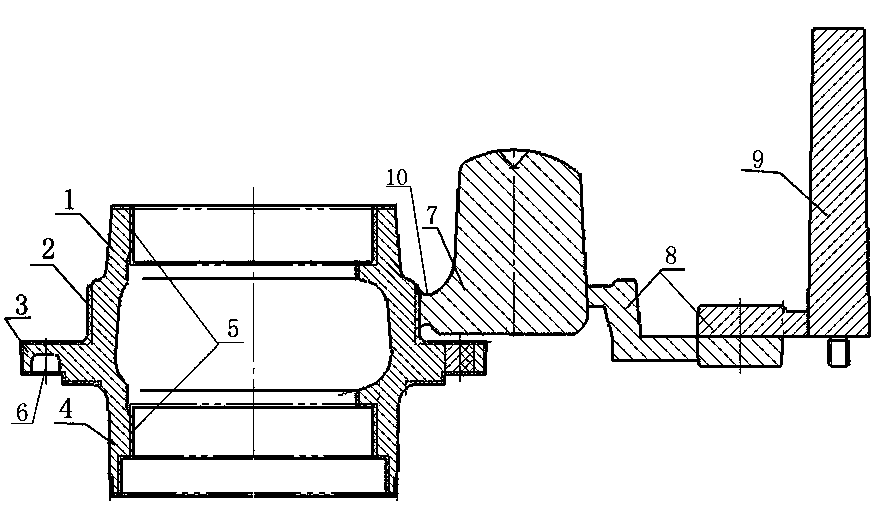

[0019] The present invention as figure 2 shown.

[0020] A pouring system for a wheel hub. The outer structure of the wheel hub is divided into a first step 1, a second step 2, a flange 3 and a straight cylinder 4 in sequence, and the interior is provided with a bearing installation position 5, and the flange 3 is provided with a mounting groove. 6. A feeding riser 7 is provided on the outer circle of the second step 2, and the feeding riser 7 is connected to the sprue 9 through the runner 8.

[0021] There is a distance between the 7 roots of the feeding riser and the 3 flanges, and the distance is 3-5 mm.

[0022] Fractures 10 are also provided on the root of the feeding riser 7 and the second step 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com