Extruding-dewatering dried tofu shaping device

A technology of extrusion dehydration and forming device, which is applied in the direction of cheese substitutes, dairy products, applications, etc., can solve the problems that the cooking staff's knife method cannot meet the requirements of the cutting edge, it is difficult to taste, and the processing method is cumbersome, so as to avoid cutting edges. The effect of excessive force on the mouth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

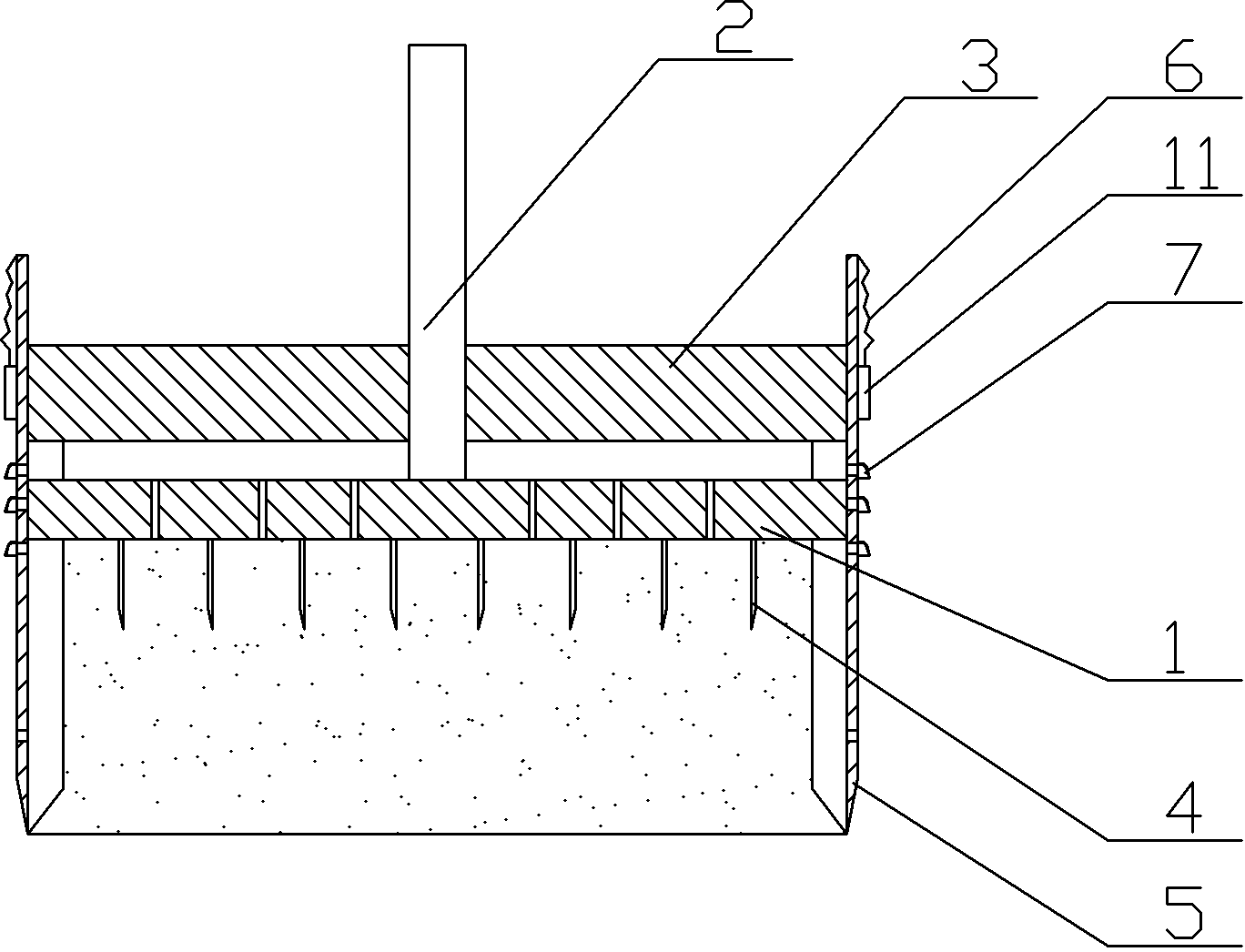

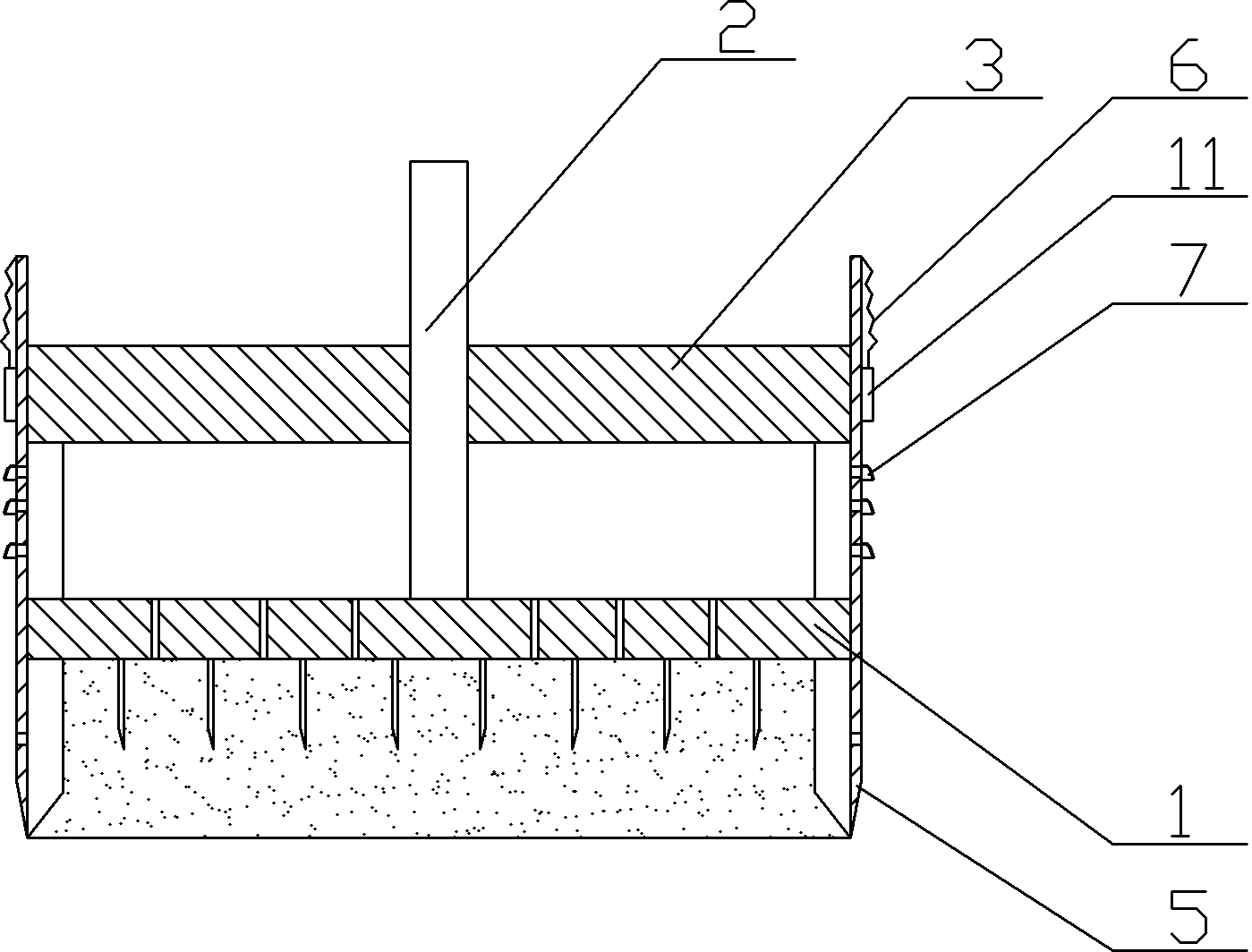

[0014] Such as figure 1 with figure 2 As shown, an extruding and dehydrating dried tofu molding device of the present invention includes a rectangular extruding plate 1, a push rod 2 arranged above the extruding plate 1, and a support plate 3 for the extruding rod 2 to pass through. , the push rod 2 is connected to the extrusion plate 1 through a ball hinge, the other end of the push rod 2 is connected to the power reciprocating equipment, a hole matching the outer diameter of the push rod 2 is opened in the center of the support plate, and a knife-edge piece 4 is vertically arranged under the extrusion plate 1 In order to improve the connection strength of the knife-edge sheet 4 and prevent it from falling off from the extruded plate 1, the extruded plate is preferably made of stainless steel metal plate, and the knife-edge sheet 4 is welded on the extruded plate 1, and slides on the side of the extruded plate 1 circumferential direction Connect with a square-shaped catch 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com