A High Efficiency Fully Integrated ac‑dc Converter

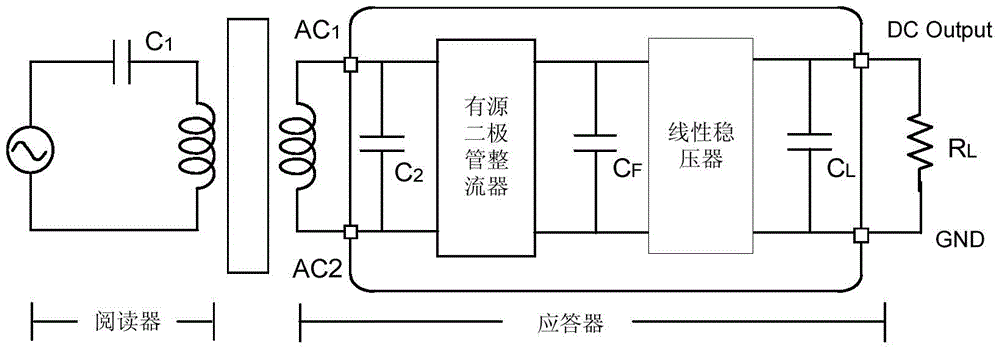

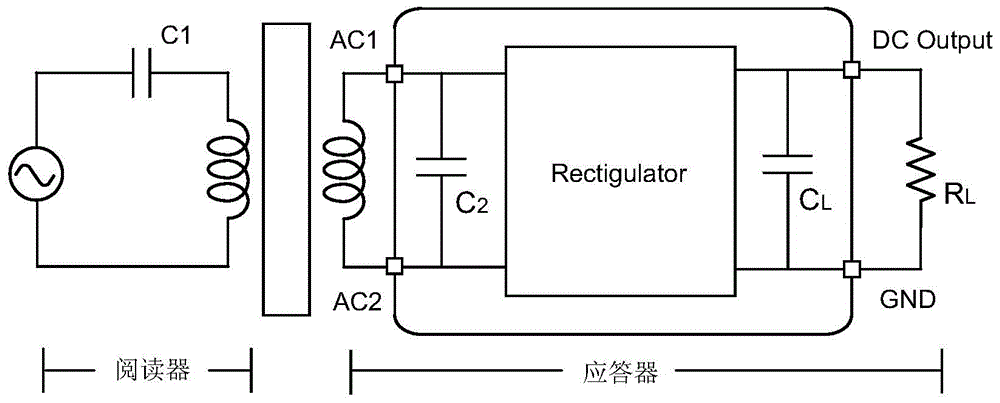

A fully integrated, converter technology, applied in the direction of output power conversion devices, AC power input conversion to DC power output, electrical components, etc., can solve problems affecting rectifier efficiency, long charge and discharge time, and reduce conversion efficiency, etc., to achieve Improve power supply noise suppression ability, ensure efficiency, and reduce output capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

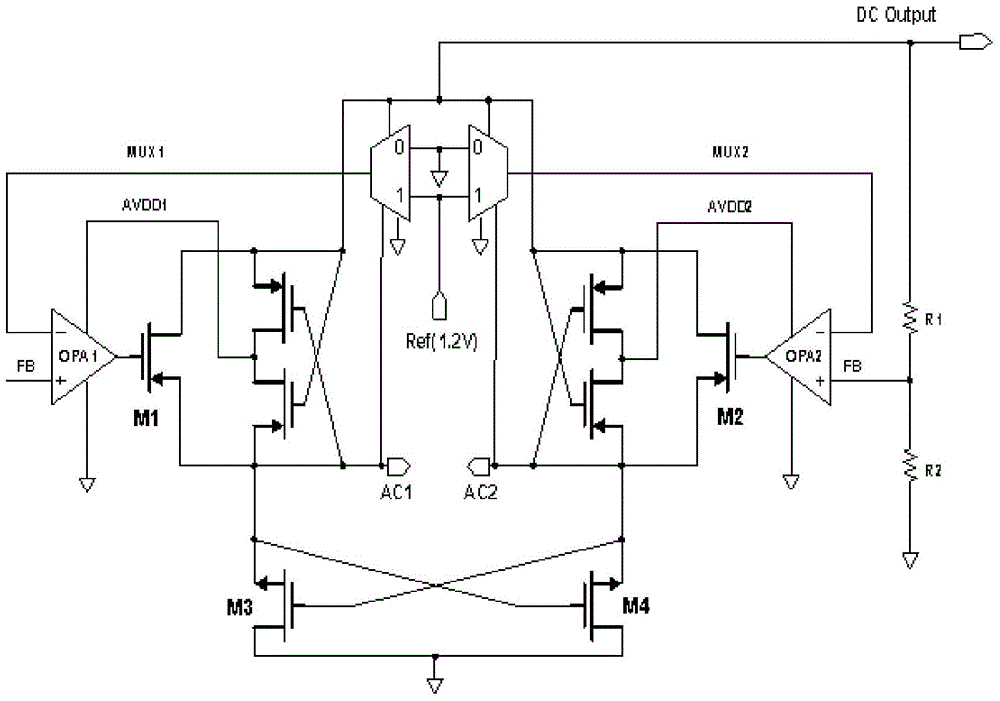

[0030] The AC-DC converter of the present invention is a simple two-port network, wherein AC1 and AC2 are input ports, and DCOutput and GND output ports are output ports. The whole AC-DC converter consists of two main parts: a self-controlled rectifier consisting of three gate crossover structures and a linear regulator with high supply voltage rejection ratio. These two parts share an output capacitor, and the size only needs 4nF, which is easy to integrate on-chip.

[0031] Among them, the core of the rectifier is a three-gate cross structure. Transistors M3 and M5 are the main paths of the AC signal from the input end to the output end, while transistors M1 and M2 are the main path of the DC signal from the input end to the ground. The transistors M4 and M6 are switches for realizing self-control, so as to avoid using a multiplexer to generate an external pulse signal to control the working path of the rectifier as in the rectigulator structure.

[0032] The working proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com