Low-torque-ripple permanent magnet motor for electric automobile

A torque fluctuation and electric vehicle technology, applied in electric vehicles, motors, electric components, etc., can solve the problems of low power density, low overload capacity, high noise, etc., to reduce torque and torque fluctuations, improve motor efficiency, Overall quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

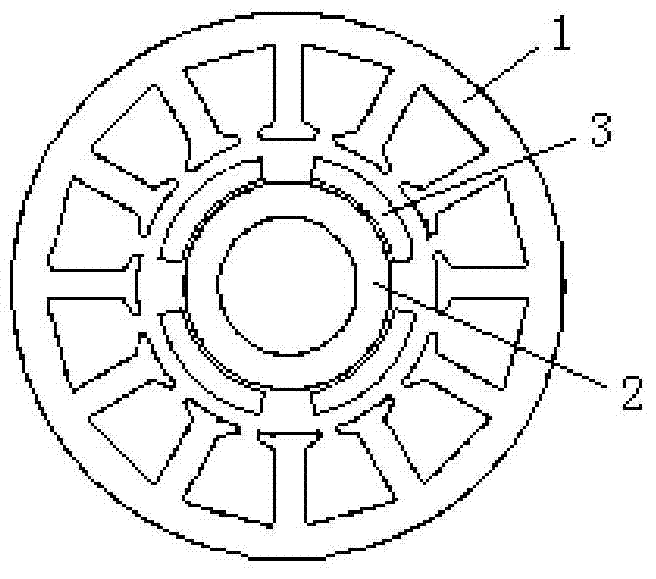

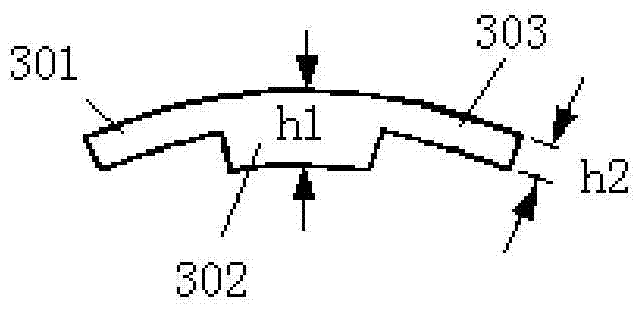

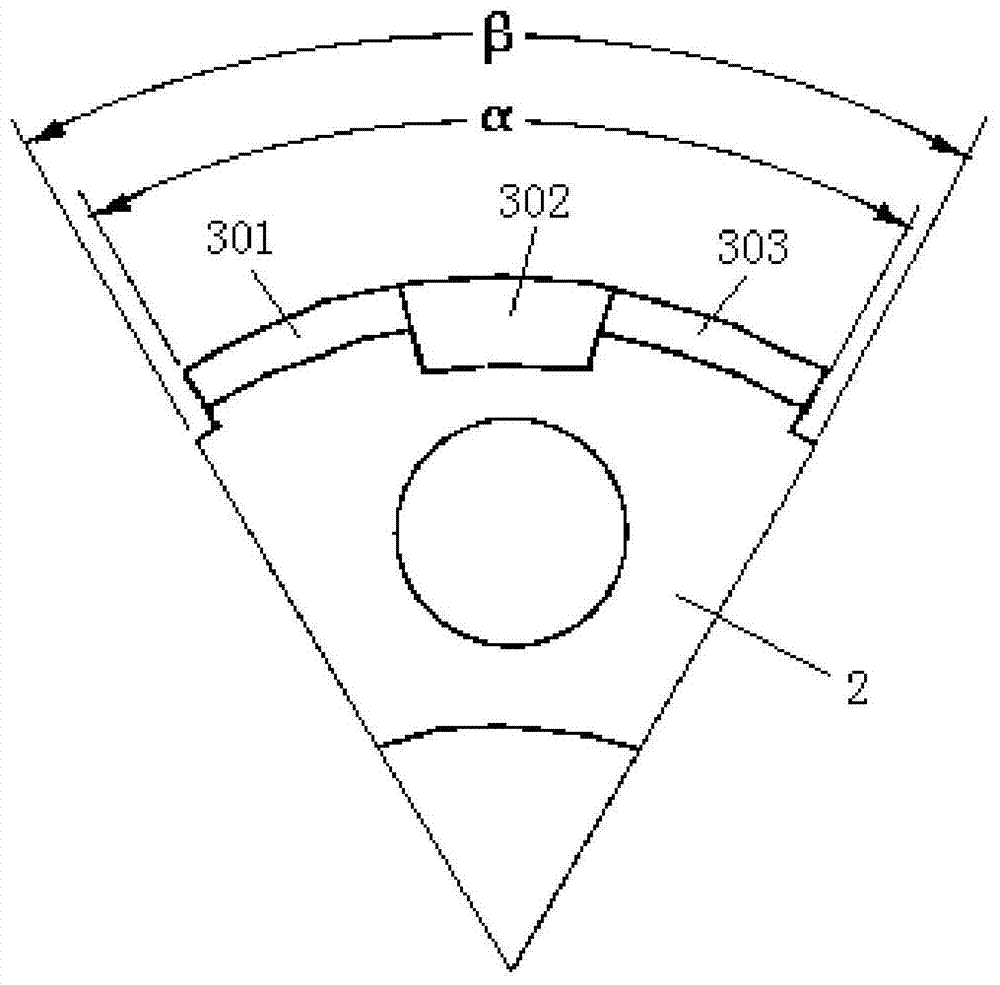

[0028] Such as Figure 1-3 As shown, a low torque ripple permanent magnet motor for electric vehicles provided by the first embodiment of the present invention includes a stator 1 and a rotor 2, and there is a uniform radial air gap between the stator and the rotor, and the rotor 2 The outer peripheral surface is axisymmetrically fixed with a plurality of surface-mounted permanent magnet poles 3 curved along the circumferential direction of the rotor in a convex arc shape, and each permanent magnetic pole 3 is arranged at intervals along the circumferential direction of the rotor;

[0029] It is characterized in that: the perm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com