Drawable socket

A plug-in and board-drawing technology, which is applied in the direction of electrical components, bases/shells, coupling devices, etc., can solve problems such as waste of sockets, and achieve the effects of reducing safety hazards, increasing the use area, and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In the following, numerous specific details are set forth in order to provide a thorough understanding of the concepts underlying the described embodiments. It will be apparent, however, to one skilled in the art that the described embodiments may be practiced without some or all of these specific details. In other instances, well known processing steps have not been described in detail.

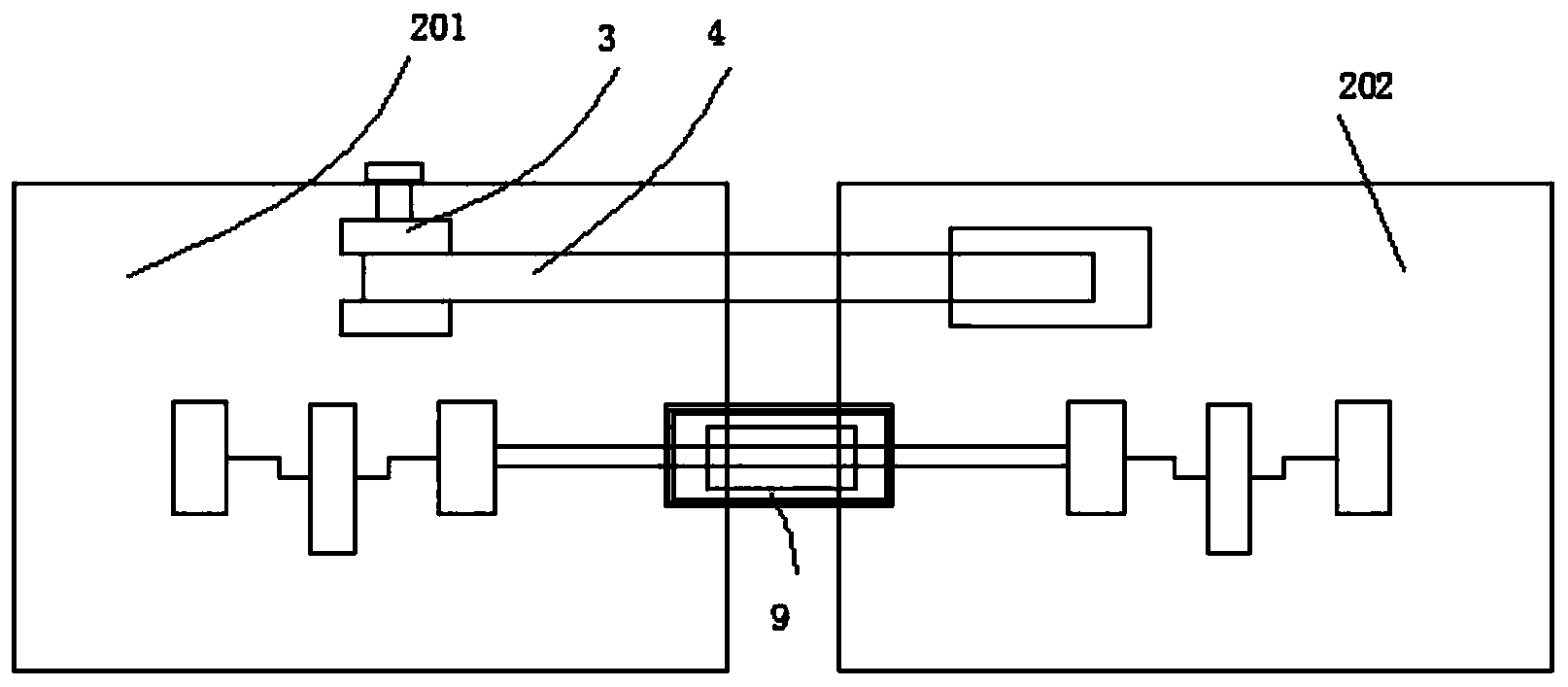

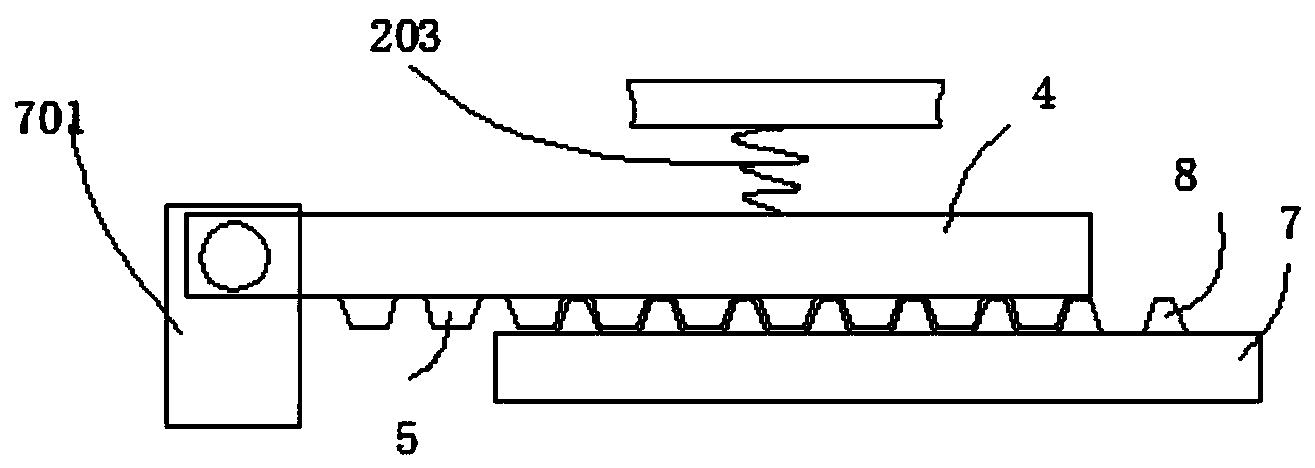

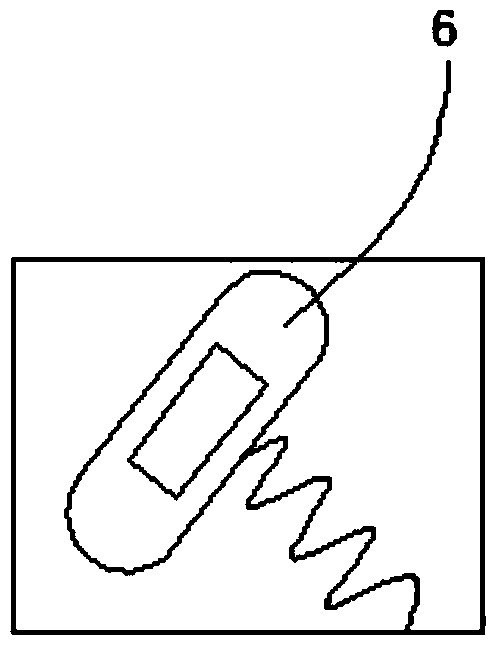

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, it includes electric wire 1, including plug-in row 2, pumping board seat 3, pumping board 4, first positioning tooth 5, knob 6, positioning plate 7, second positioning tooth 8, spring tube 9, and the plug-in row 2 Including the first plug-in row 201 and the second plug-in row 202, the pumping board seat 3 is located at the inner bottom of the first plug-in row 201, the two are glued together, the pumping board 4 is located inside the pumping board seat 3, the two The first positioning tooth 5 is located at the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com