A kind of lcos micro display device liquid crystal cell structure and manufacturing method thereof

A technology of a microdisplay device and a manufacturing method, which is applied in instruments, nonlinear optics, optics, etc., can solve the problems of limited resolution and contrast, and cannot be used at high temperature, and achieves improved light transmittance, good mechanical properties, The effect of increasing the contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

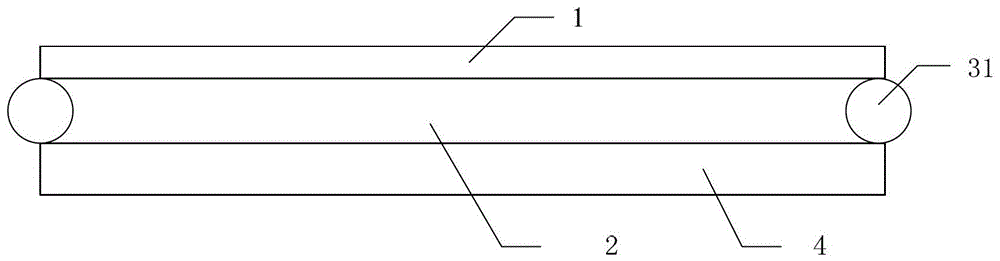

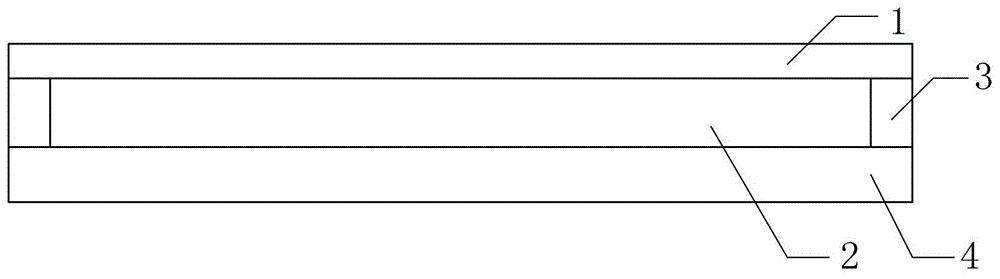

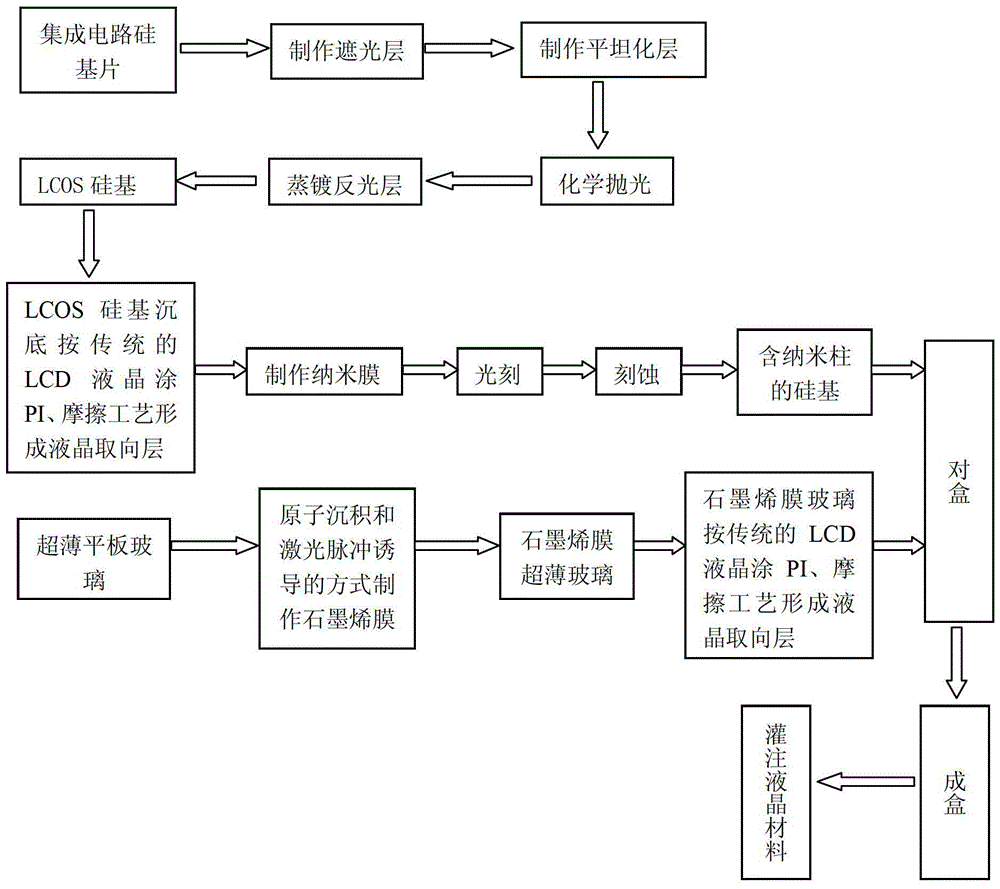

[0050] Such as figure 2 As shown, a liquid crystal cell structure of a LCOS microdisplay device, the liquid crystal cell structure is a layered structure, including an electrode layer 1 on a graphene film, a liquid crystal material layer 2, a nano-column 3 and a silicon-based substrate layer 4, a silicon-based The substrate layer 4 is located in the lower layer, the upper electrode layer 1 is located in the upper layer, the liquid crystal material layer 2 and the nano column 3 are located in the middle layer, and the thickness of the liquid crystal cell can be adjusted by changing the height of the nano column 3 .

[0051] The main differences between the present invention and the prior art are:

[0052] 1. The upper electrode layer 1 is a graphene film flat glass.

[0053] The graphene film is used to replace the ITO film to improve the light transmittance, temperature stability and optical density of the light engine of the LCOS device. Introduce graphene technology, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com