Continuity test device and continuity test method of airborne cable

A continuity test and cable technology, applied in the field of the continuity test device for airborne cables, can solve the problems of relying on labor, cumbersome steps, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

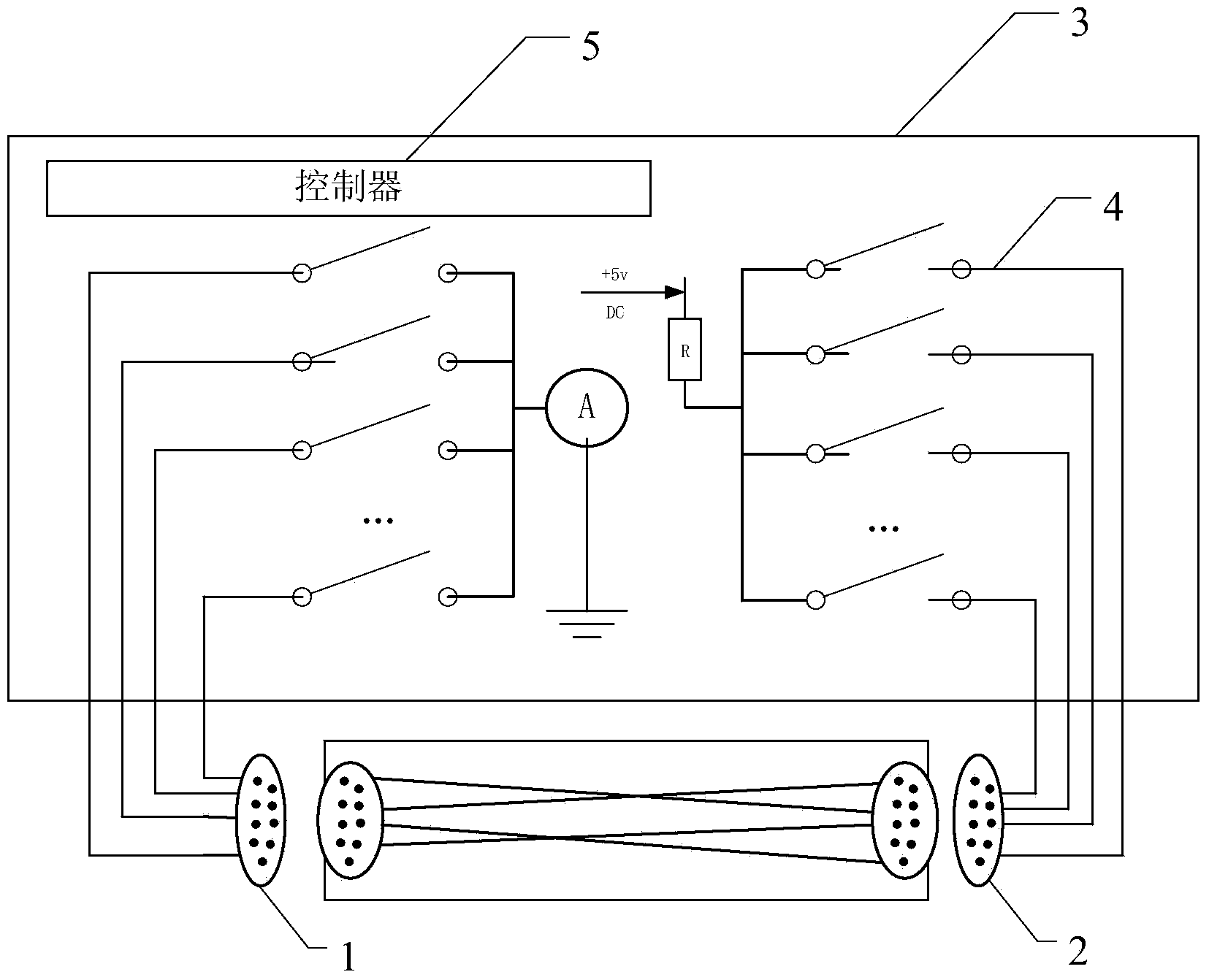

[0035] figure 1 It is a schematic structural diagram of an airborne cable conduction test device provided in this application.

[0036] refer to figure 1 As shown, the conduction test device of the airborne cable in the embodiment of the present application is used to perform a conduction test on the airborne cable after the final assembly, including:

[0037] Output connector 1, input connector 2 and test host 3;

[0038] In the embodiment of the present application, the continuity test device provides a test cable, an output terminal connector, and an input terminal connector that are matched with the cable connector of the airborne cable to be tested, so that after the deployment of the airborne cable to be tested is completed, Inserting the output end connector and the input end connector into the cable connectors at both ends of the airborne cable to be tested realizes end-to-end connection and testing of the test cable and the airborne cable to be tested. At this time...

Embodiment 2

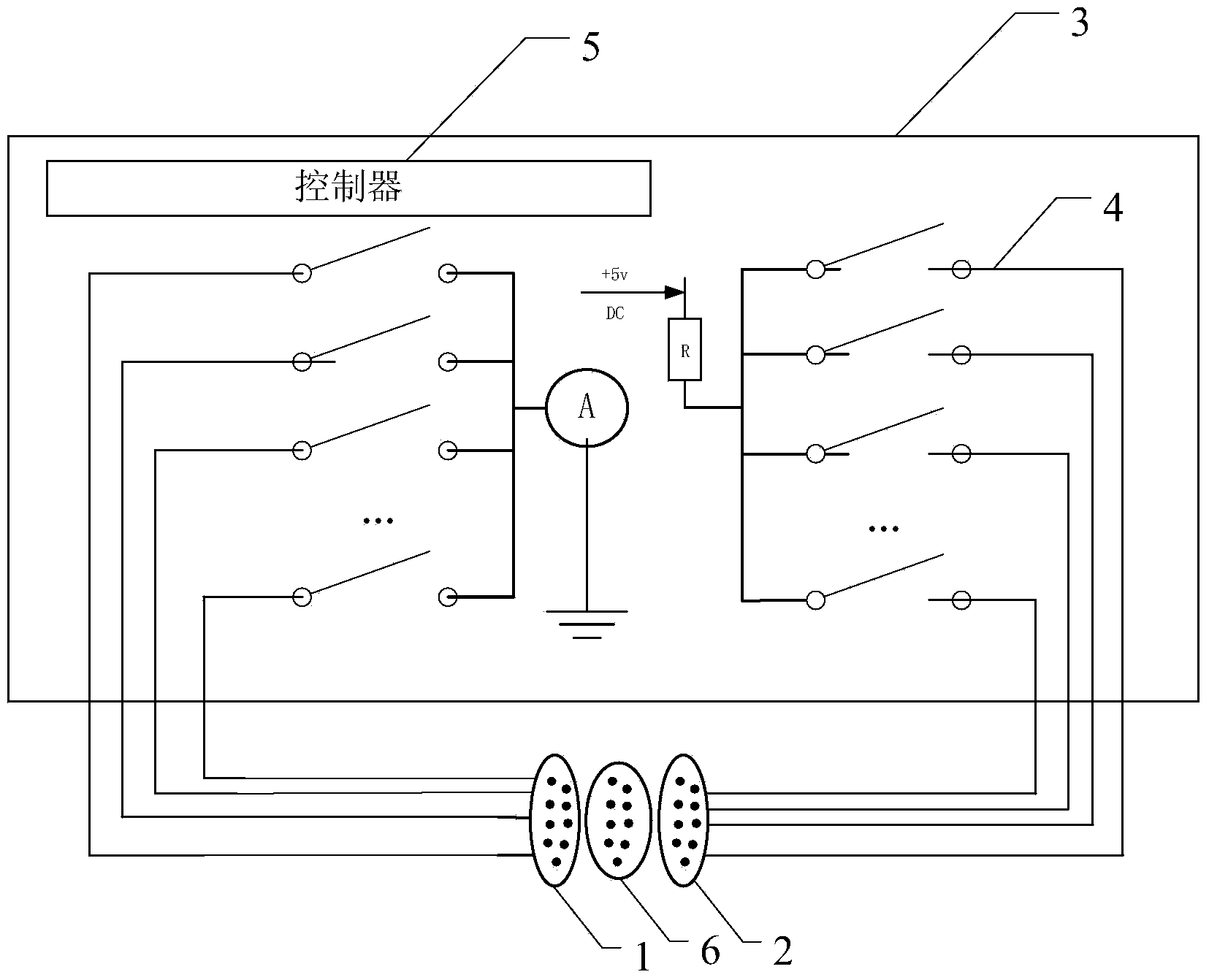

[0049] figure 2 It is a schematic structural diagram of another airborne cable conduction test device provided in this application.

[0050] refer to figure 2 As shown, the conduction test device of the airborne cable provided by the embodiment of the present application includes:

[0051] Output connector 1, input connector 2, self-test connector 6 and test host 3;

[0052] The output connector 1 and the input connector 2 can be respectively connected to the cable connectors at both ends of the airborne cable to be tested, and the multiple core wires in the output connector 1 are connected to the The multiple core wires in the airborne cable correspond one-to-one, and the multiple core wires in the input connector 2 correspond to the multiple core wires in the airborne cable to be tested;

[0053] The test host 3 is provided with multiple test circuits 4 and controllers 5;

[0054] Each test circuit 4 is composed of an output terminal, a relay, a power module, a test re...

Embodiment 3

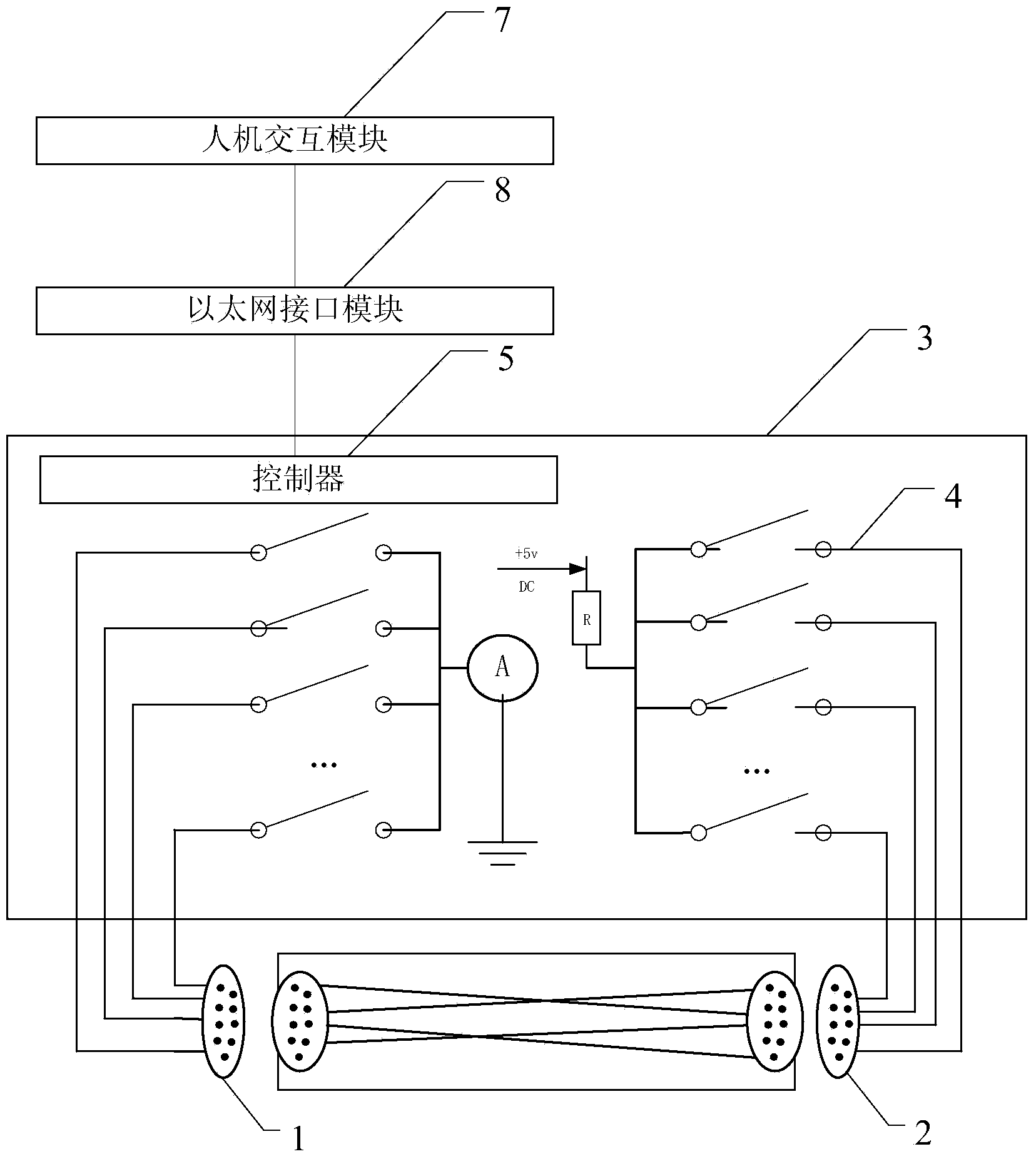

[0062] image 3 It is a schematic structural diagram of another test device for continuity of an airborne cable provided by the present application.

[0063] refer to image 3 As shown, the conduction test device of the airborne cable in the embodiment of the present application is used to perform a conduction test on the airborne cable after the final assembly, including:

[0064] Output connector 1, input connector 2 and test host 3;

[0065] The output connector 1 and the input connector 2 can be respectively connected to the cable connectors at both ends of the airborne cable to be tested, and the multiple core wires in the output connector 1 are connected to the The multiple core wires in the airborne cable correspond one-to-one, and the multiple core wires in the input connector 2 correspond to the multiple core wires in the airborne cable to be tested;

[0066] The test host 3 is provided with multiple test circuits 4 and controllers 5;

[0067] Each test circuit 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com