Coal quality evaluating method and distributing method of highly-metamorphic coking coal based on coke optical texture structure

A technology of optical structure and evaluation method, which can be used in coking ovens, petroleum industry, fuel oil testing, etc., and can solve the problem of wasting coking coal resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with specific embodiments.

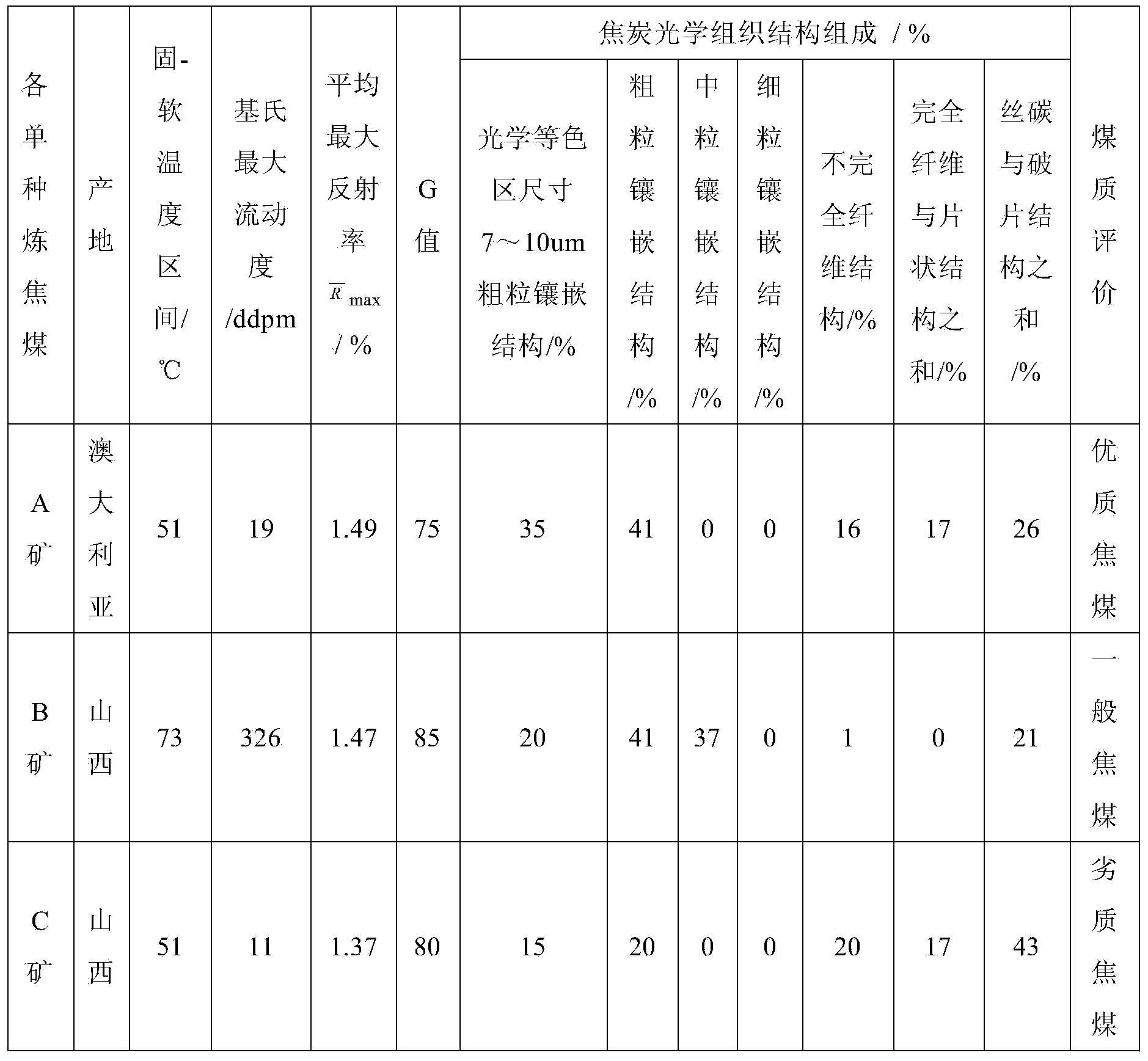

[0020] A factory has 8 procurement channels for coking coal resources, of which 3 are Coking coal between 1.35% and 1.50%, numbered as A mine, B mine, and C mine, respectively measured the average maximum reflectance of each single coking coal and single coal-formed coke coke optical structure, its coal quality has been discriminated and evaluated, and it is used according to the matching method in the present invention. The evaluation results can be seen in Table 1.

[0021] Table 1 The degree of metamorphism, coking optical structure and coal quality evaluation of each single coal

[0022]

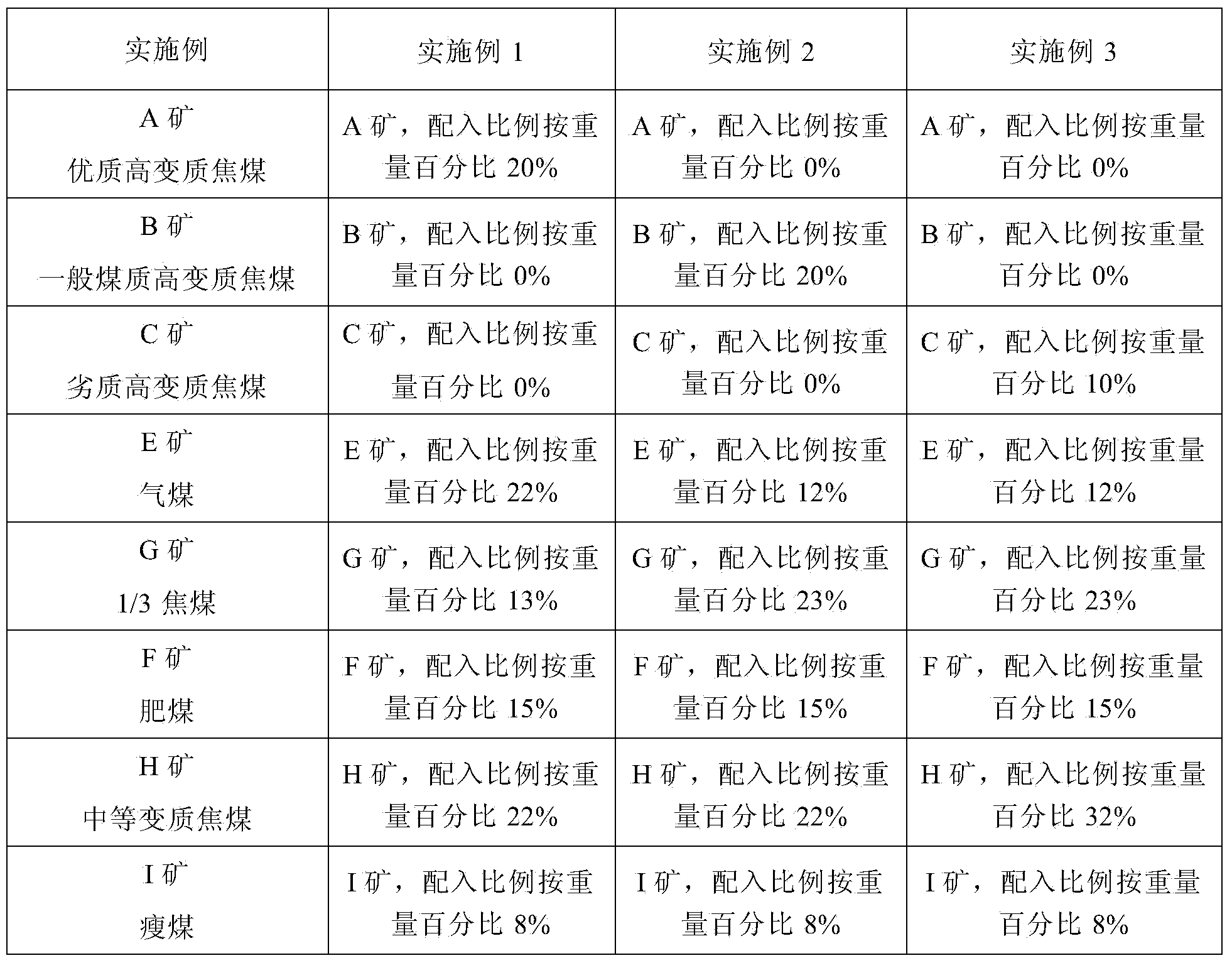

[0023] According to the evaluation results in Table 1, a coal blending test was carried out, and the specific coal blending examples 1-3 are shown in Table 2.

[0024] Coal blending scheme of table 2 embodiment 1~3

[0025]

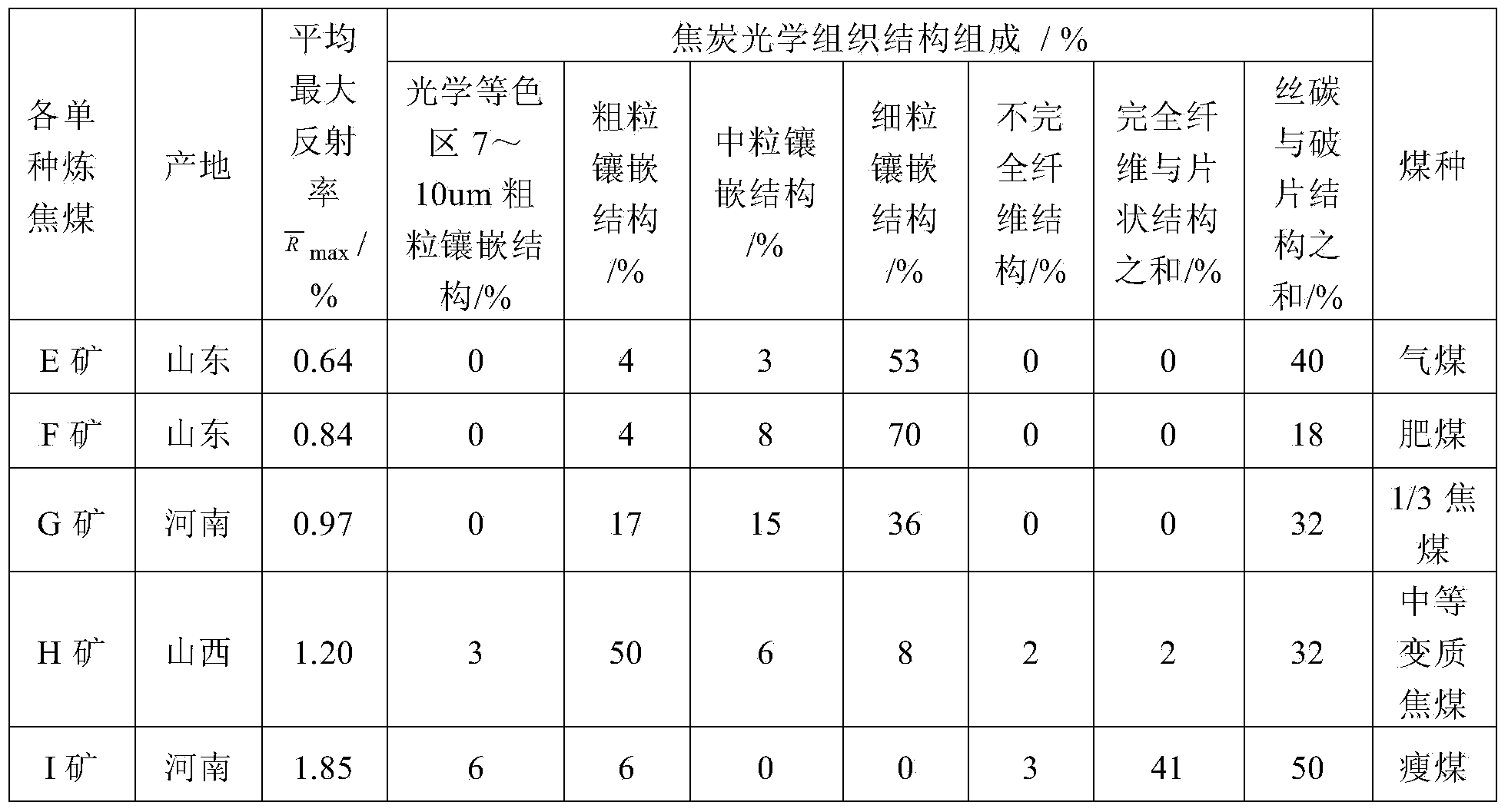

[0026] See Table 3 for other coal typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com