All-aluminum bus detachable transport bracket

A transport rack and detachable technology, which is applied in the direction of transport and packaging, external frames, assembly vehicles, etc., can solve the problems of insufficient space utilization, inconvenient operation, and difficult fixation, so as to save transportation costs and material costs, and facilitate low-cost Easy to operate and occupy a small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

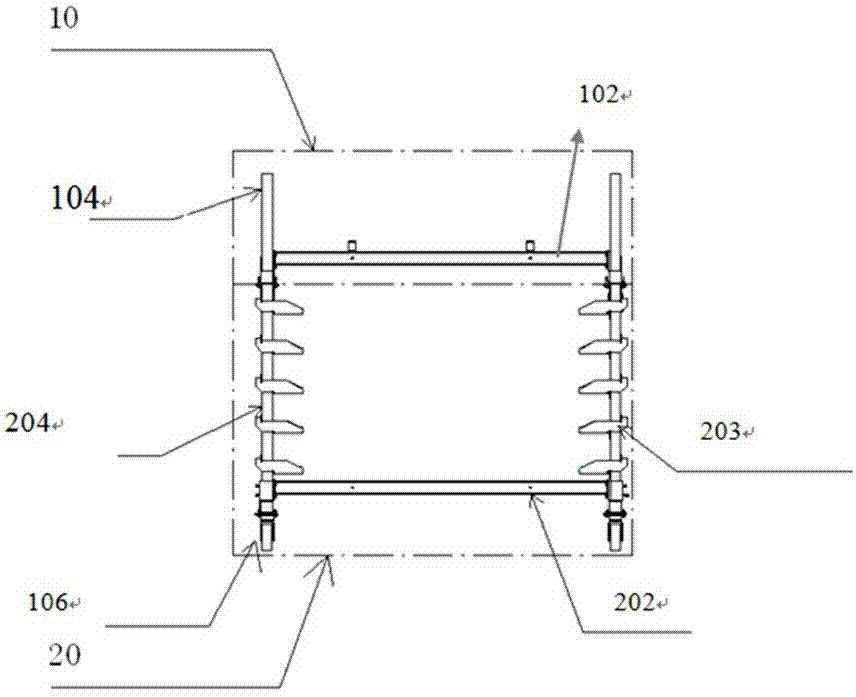

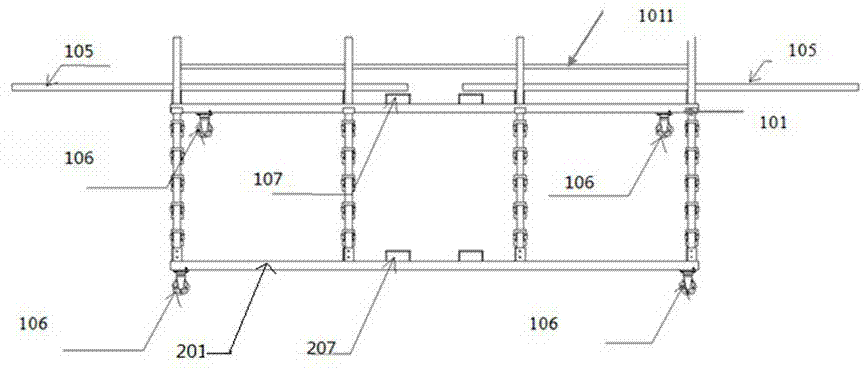

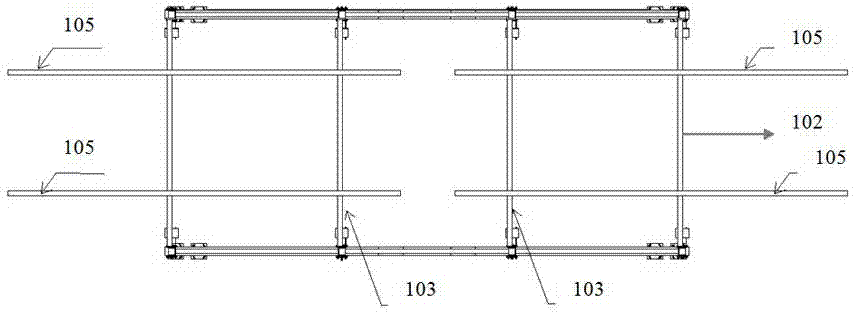

[0022] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments are not limited to the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included within the protection scope of the present invention. refer to Figure 1 to Figure 3 The present invention shown is a detachable transport rack for all-aluminum buses, which is characterized in that: it includes a transport rack superstructure 10 for storing left and right side enclosure products 100 of a bus and a transport rack superstructure 10 for storing a bus roof product 200 The lower structure 20 of the transport rack, the upper structure 10 of the transport rack can be stacked on the lower structure 20 of the transport rack; the upper structure 10 of the transport rack includes: a long connecting beam 101 and a short connecting beam 102 at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com