Buoy type filter

A filter and buoy type technology, which is applied in the field of sewage treatment, can solve the problems of shortening the service life of thick and short filters, complicated dirt, and reducing the passing speed of sewage, so as to achieve the effect of maintaining filtration efficiency, good filtration effect, and self-cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

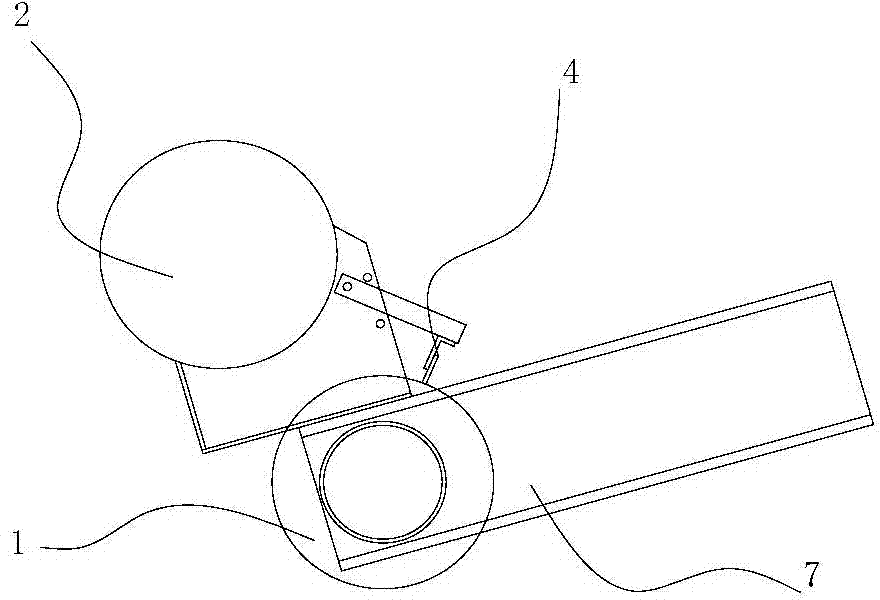

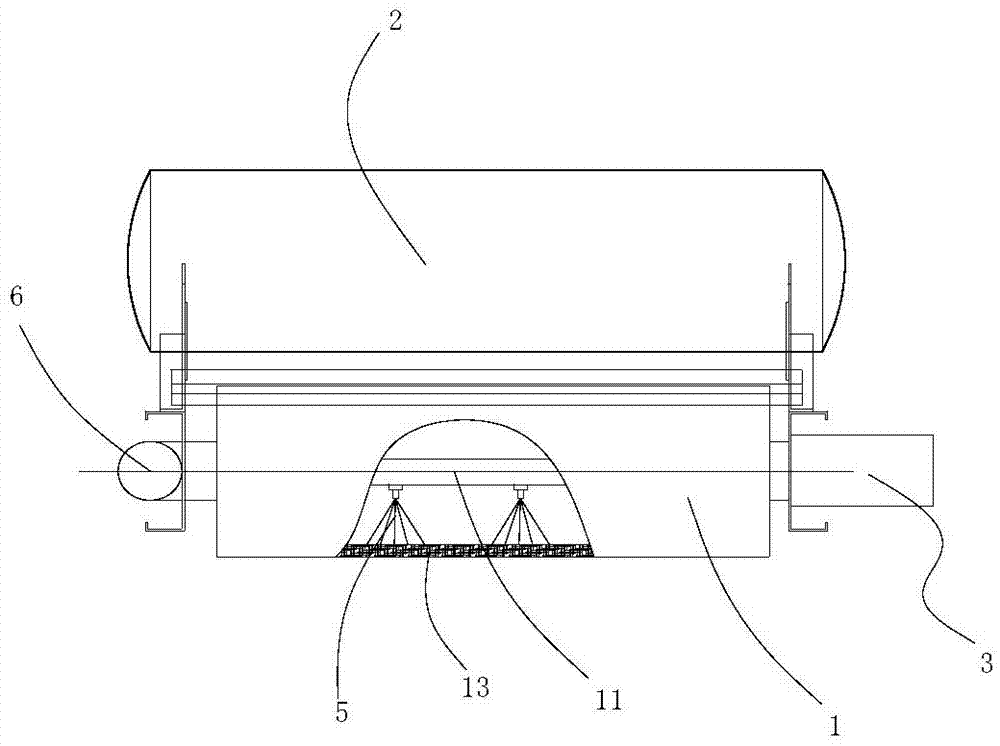

[0015] Such as figure 1 and figure 2 As shown, the buoy filter of the present embodiment includes a sieve drum 1, a power source 3, a buoy 2 and a fixed plate 7, and the buoy 2, the power source 3 are all fixedly connected to the fixed plate 7; the sieve drum 1 is installed on the fixed plate and Driven by a power source to rotate, the sieve drum 1 is a hollow cylinder, and the outer wall of the sieve drum 1 is provided with a number of filter holes, all the filter holes form a filter net 13, and the side of the sieve drum 1 is provided with a water outlet 6.

[0016] In this embodiment, the power source 3 adopts a motor, of course, the power source 3 may also adopt other transmission mechanisms such as a rack and pinion or a pulley.

[0017] Usually large impurities in water are deposited below the sewage. In this embodiment, the buoyancy of the buoy 2 is used to ensure that the sieve drum 1 filters the clearer sewage in the upper layer, which contains less impurities, whic...

Embodiment 2

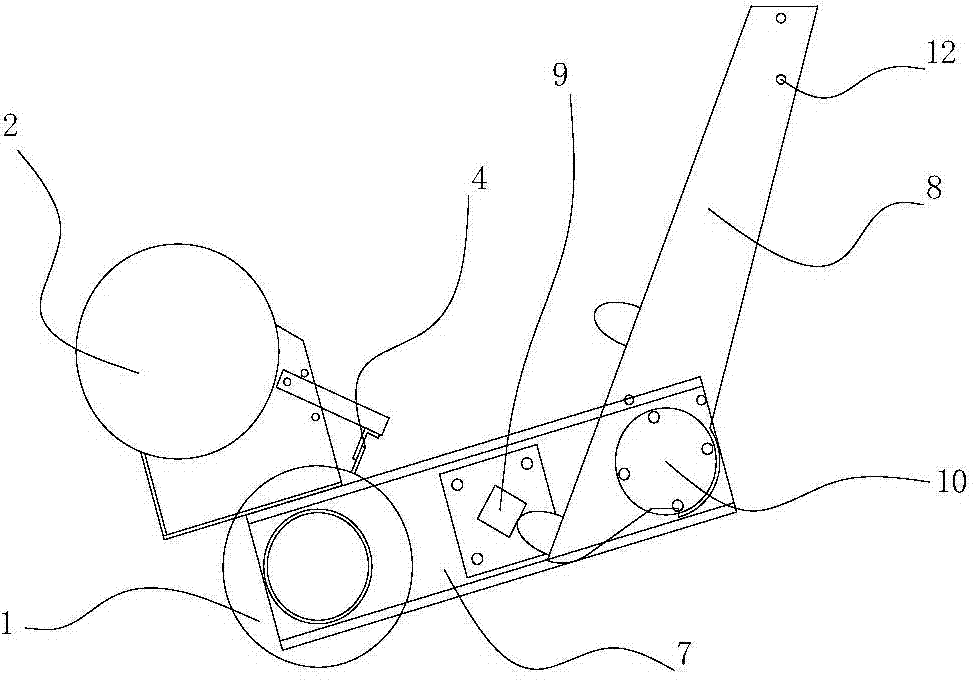

[0022] This embodiment is an improvement on the basis of Embodiment 1, and the difference from Embodiment 1 is that: image 3 As shown, the screen drum 1 and the buoy 2 are located at one end of the fixed plate 7, and the other end of the fixed plate 7 is hinged with a mounting plate 8, namely image 3 The mounting plate 8 shown in the figure can rotate around the rotating shaft 10; the fixed plate 7 is provided with a limit block 9, and the end of the mounting plate 8 close to the screen drum 1 is offset against the limit block 9. In this way, the relative position of the buoy 2 and the screen drum 1 remains unchanged, and at the same time, the two relative to the fixed position can be adjusted within a certain height range around the rotating shaft 10 under the action of buoyancy.

[0023] In this embodiment, an installation hole 12 for installing a counterweight can also be provided at the end of the installation plate 8 away from the screen drum 1, so that the height of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com