Sintering furnace with a gas removal device

A technology for exhaust devices and sintering furnaces, which is applied in the field of sintering furnaces and can solve problems such as high fragility and reduced hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

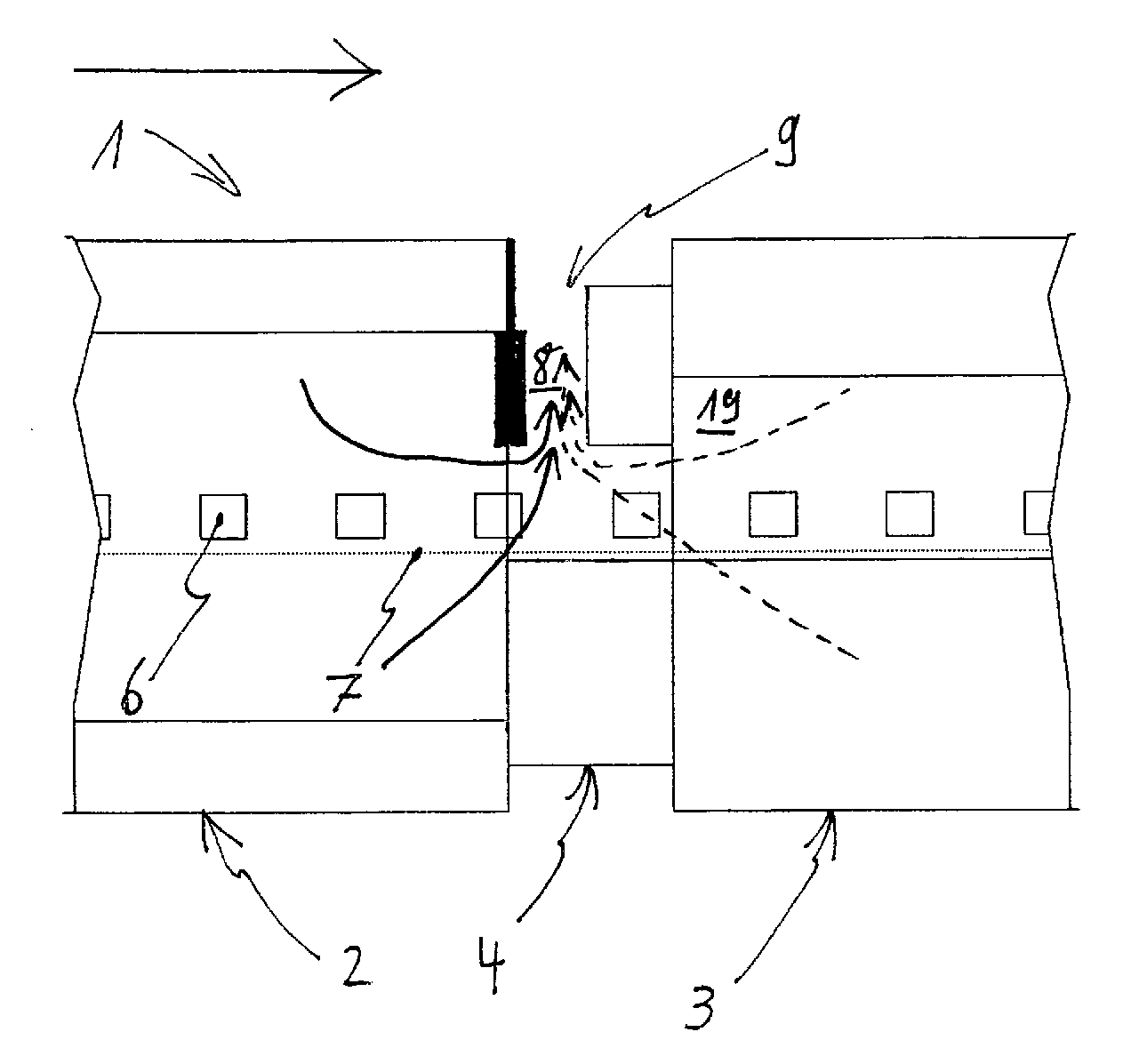

[0062] Figure 1a A sintering furnace 1 in the form of a belt sintering furnace according to the prior art is shown in plan view. In this case, the sintering furnace 1 has a furnace inlet 16 , a first zone 2 configured as a burnout zone, a transition zone 4 , a second zone 3 configured as a sintering zone, a cooling Zone 17 and outlet 18 of the sintering furnace. The green bodies 6 to be sintered lie on a conveying surface 7 which, in the sintering furnace 1 shown, is designed as a sintering belt. In addition, in the sintering furnace 1 shown, muffle walls 19 are arranged on both sides of the conveying surface 7, which are arranged parallel to the boundary line of the conveying surface 7 of the sintering furnace 1 at the provided conveying surface. Viewed in direction, the start of the transition zone 4 extends along the sintering zone 3 to the end of the cooling zone 17 .

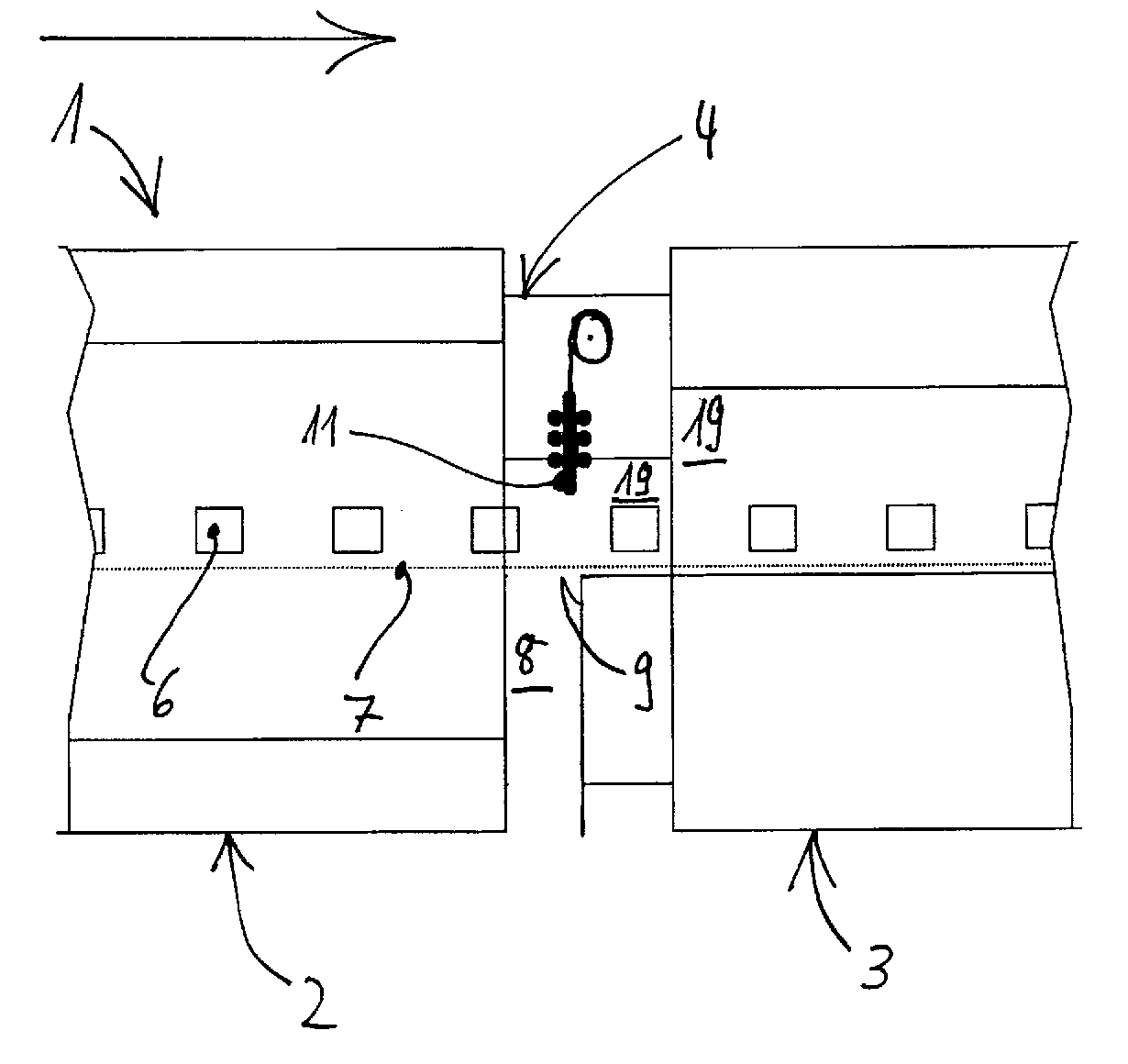

[0063] Figure 1b A sintering furnace 1 constructed as a belt sintering furnace according to the pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com