Design method of X-ray flattening filter

A design method and homogenizer technology, applied in radiation/particle processing, using aperture/collimator, nuclear engineering, etc., can solve the problems of increased design time, complicated design process, etc., and achieve low design cost and good homogenization effect. , the effect of short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

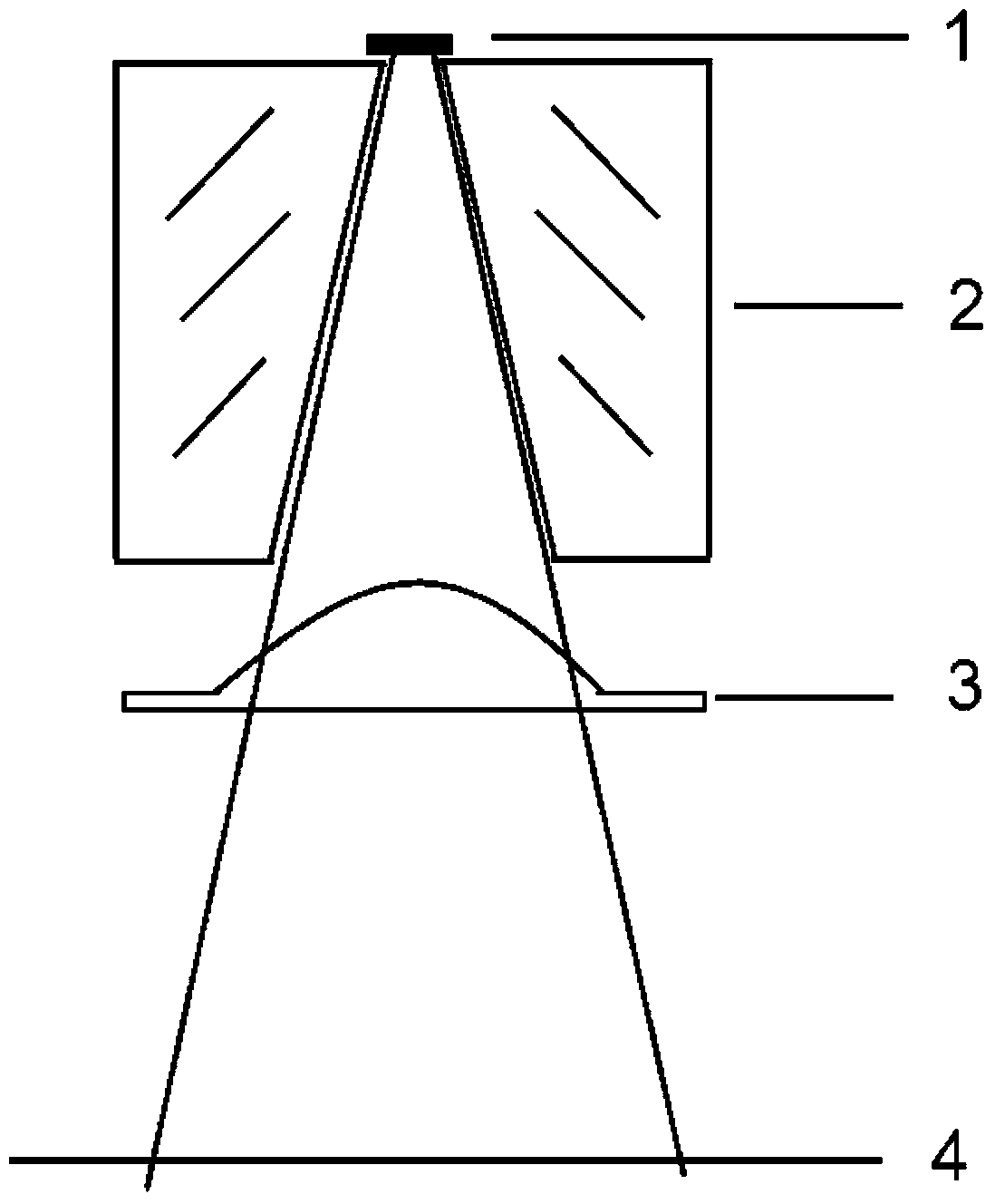

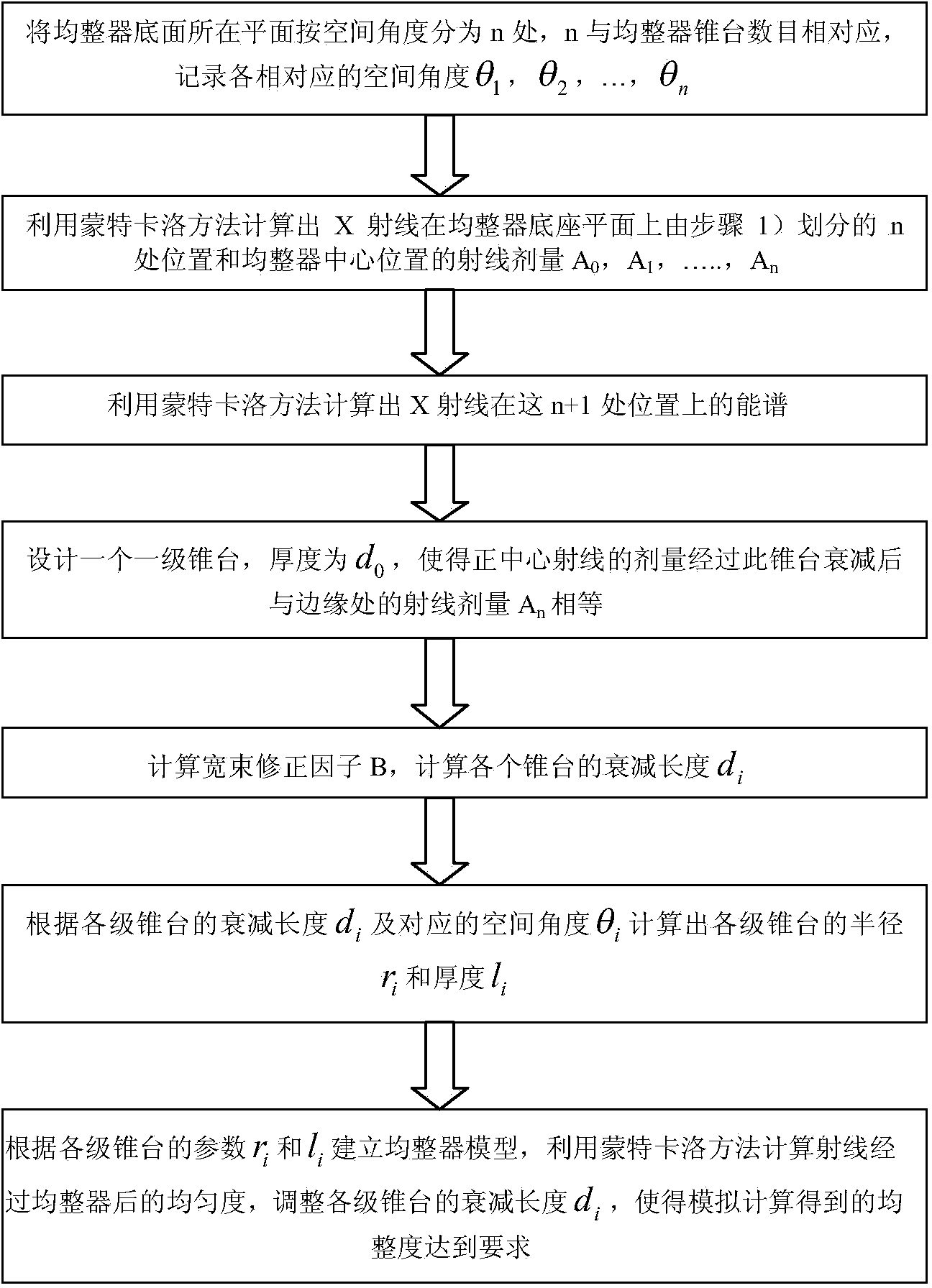

[0036] figure 1 is a schematic diagram of the homogenizer, image 3 It is a schematic flow chart of the method of the present invention.

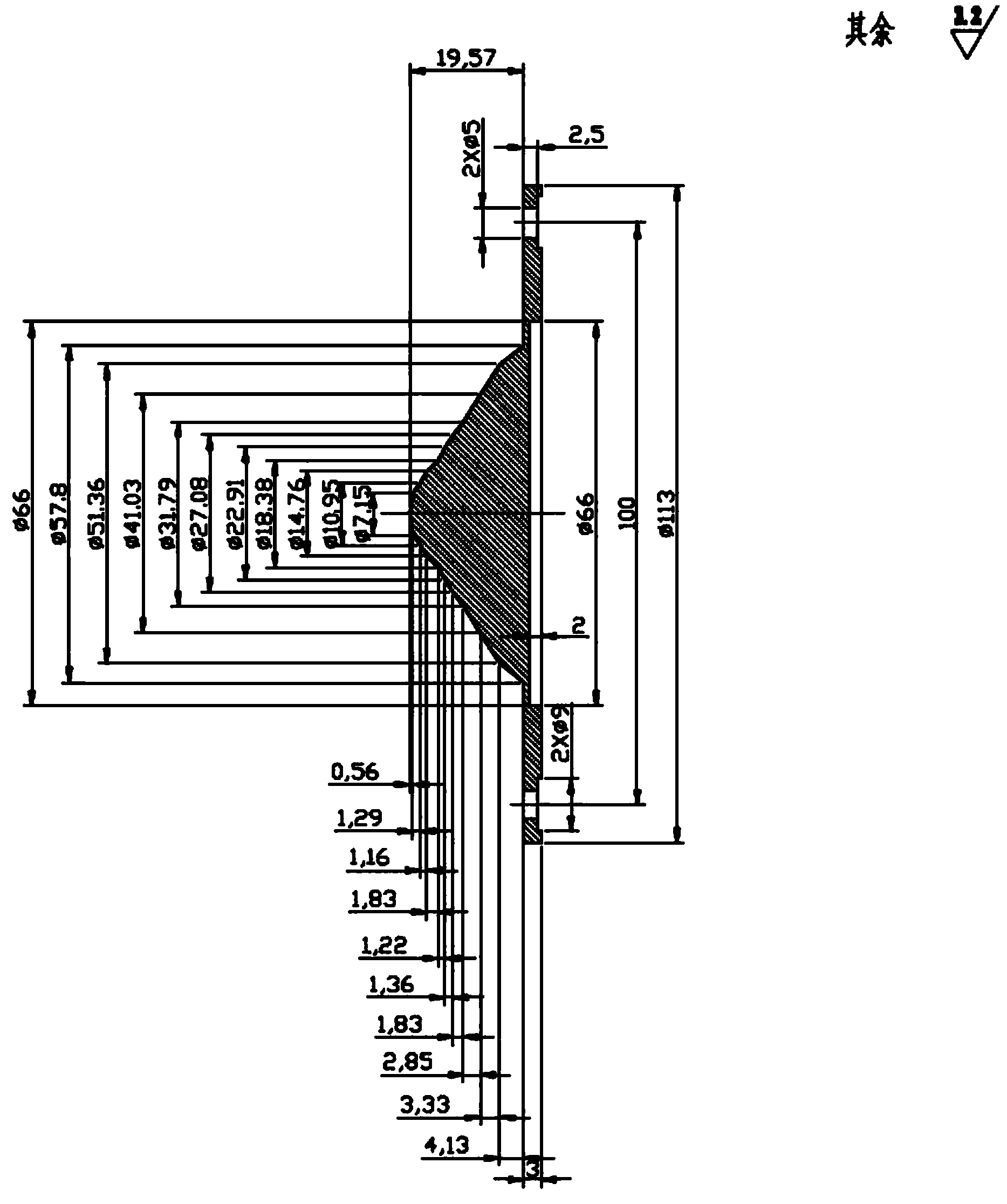

[0037] Taking the design of the homogenizer of the 6MeV medical electron accelerator as an example, the method of the present invention is described in detail, figure 2 It is a cross-sectional view of the structure of the 6MeV medical accelerator homogenizer in this embodiment. The technical requirements of this figure are: 1. The dimensional tolerance of the tapered boss is processed according to IT8 grade, and the rest of the dimensional tolerances are processed according to IT10 grade; 2. The material is brass.

[0038] Specifically include the following steps:

[0039] 1) The distance between the leveler base and the ray source target point is L=128mm, and the ray opening angle is 14°. Set up a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com