Novel forklift type AGV (automatic guided vehicle) trolley

A new type of technology, applied in vehicle position/route/height control, hoisting device, non-electric variable control, etc., can solve the problems of traditional differential drive AGVs failing to achieve precise positioning and robot control methods not being introduced. The effect of smaller turning radius, flexible steering and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

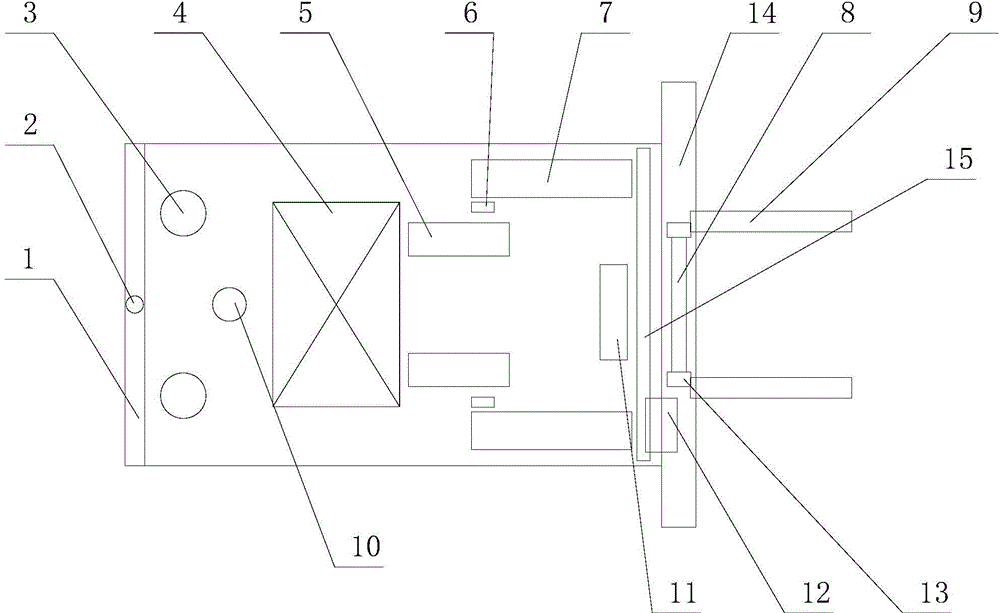

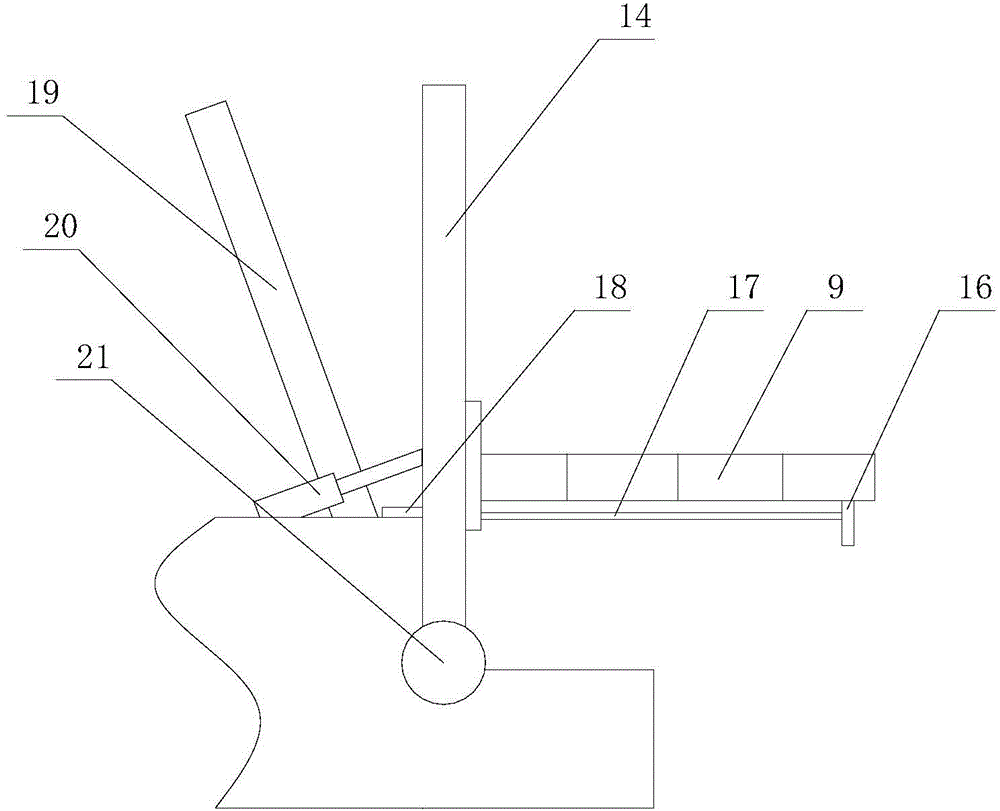

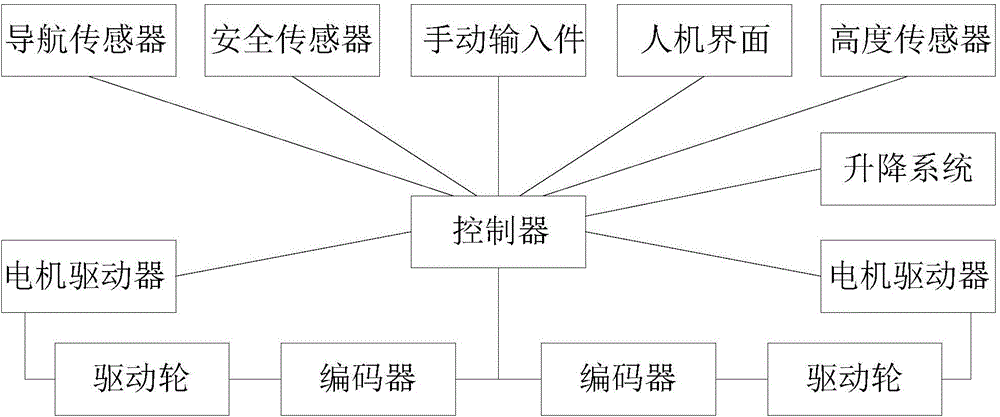

[0024] Such as figure 1 , figure 2 , image 3 As shown, a new type of forklift AGV trolley includes a car body. The front part of the car body is provided with a lifting system. The lifting system is connected to a material fork 9 through transmission. The middle part of the body is provided with a two-wheel differential drive device, which is connected with a multifunctional integrated control device. A protective device 1 is arranged around the vehicle body. The bottom of the vehicle body is provided with an adaptive moving mechanism.

[0025] In this embodiment, the two-wheel differential drive device includes driving wheels 7 symmetrically arranged on both sides of the car body, each driving wheel 7 is connected to a motor 5, and the motor 5 is connected to a motor driver, and all the motor drivers are connected to All-in-one control unit. An encoder 6 is installed on the motor 5 or the driving wheel 7, and the encoder 6 is connected to a multifunctional integrated c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com