Material compression creep test device

A compression creep and test device technology, which is used in measuring devices, analyzing materials, and testing the strength of materials by applying stable tension/pressure. Inaccurate results, etc., to achieve the effect of simple and clear structure principle, small footprint, and reliable test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

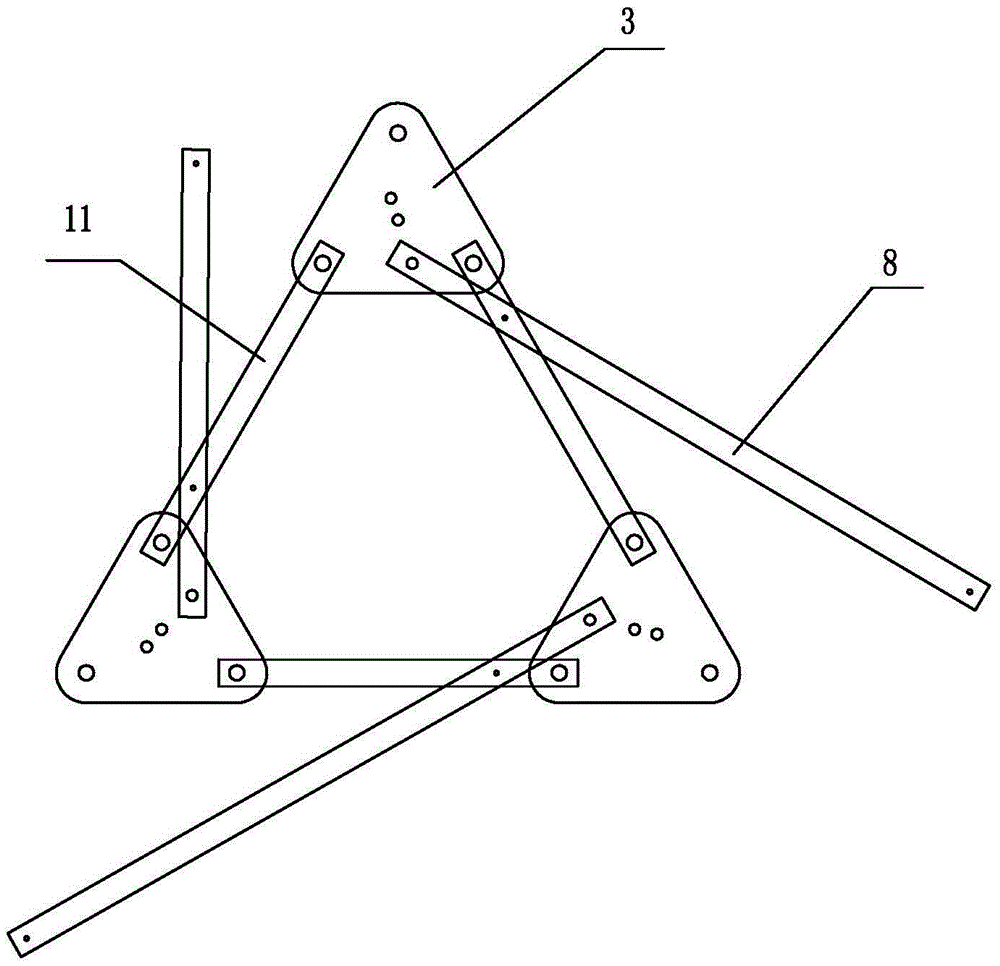

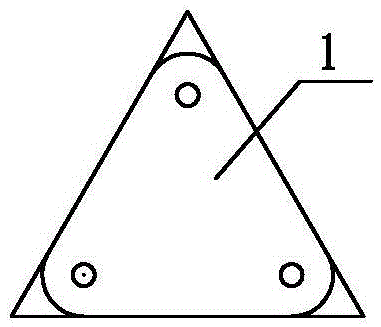

[0029] Specific embodiments: for illustration in conjunction with the accompanying drawings, the material compression creep test device of this embodiment includes three sets of compression loaders A, the three sets of compression loaders A are arranged in a ring, and the adjacent two sets of compression loaders A The upper and lower ends are connected by the connecting rod 17 and the connecting plate 11; each set of compression loader A includes the first fixed plate 1, the second fixed plate 2, the third fixed plate 3, the fourth fixed plate 19, the first sliding plate 4. The second sliding plate 5, three first columns 6, three second columns 7, three third columns 20, lever 8, first movable pulley 9, heavy object carrying basket 10, second movable pulley 12, first Rope 13, second rope 14, third rope 18 and connecting rod 15;

[0030] The first fixed plate 1, the fourth fixed plate 19, the second fixed plate 2 and the third fixed plate 3 are arranged horizontally from bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com