Multi-material weighing method

A weighing and material technology, applied in the direction of weighing, measuring devices, instruments, etc., can solve the problems that the efficiency cannot keep up with the production needs, the formula is easy to leak, and it is difficult to record the weighing weight of main materials and auxiliary materials, so as to improve the weighing The effect of improving efficiency and improving weighing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

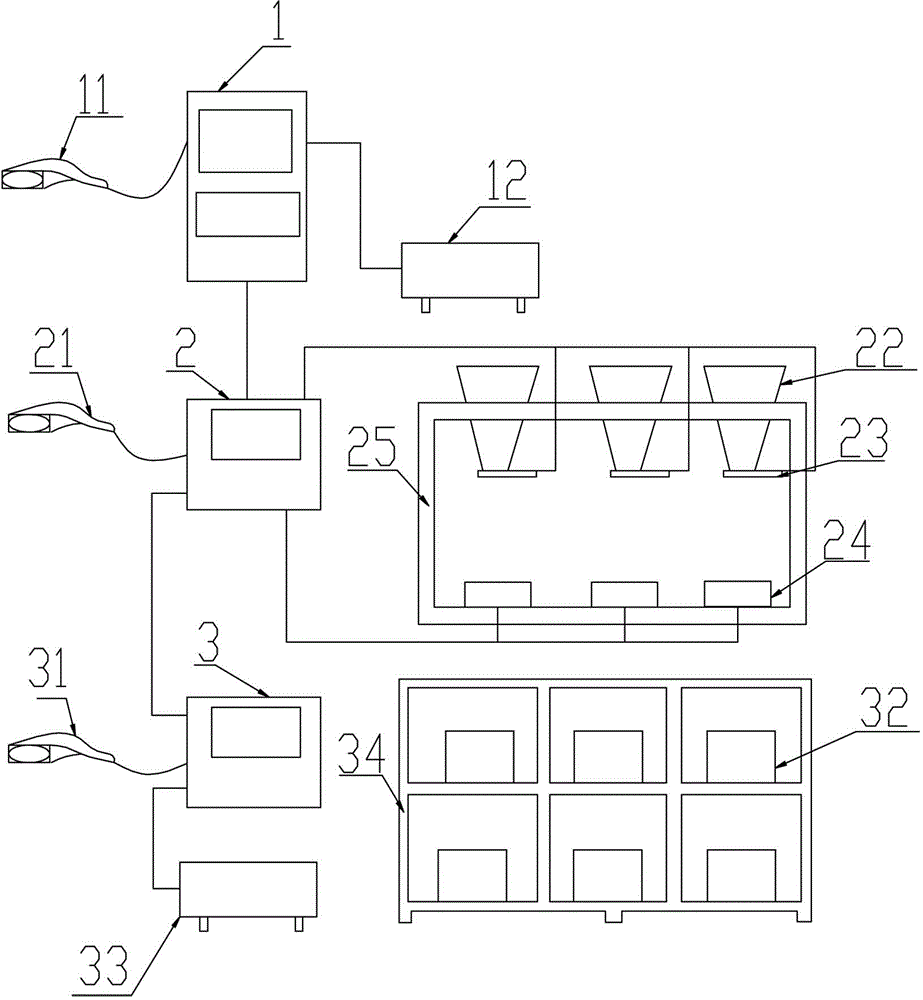

[0015] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

[0016] A variety of material weighing methods, the method steps are as follows:

[0017] 1) After the formula designer has finished designing the formula, he inputs the formula into the main controller 1, and then uses the first code reader 11 connected to the main controller 1 to scan the barcode, so that the barcode corresponds to the formula to form a formula barcode;

[0018] 2) Workers use the second code reader 21 connected to the main material controller 2 to scan the formula barcode and the barcode of the worker's own job number. At this time, the worker's job number barcode will be recorded by the main material controller 2, and the main material The controller 2 will read the formula corresponding to the formula barcode from the master controller 1 connected to it according to the formula barcode, and the name and weight of each main m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com