Assembled type jacking pipe piece structure and assembling method thereof

An assembled, segmented technology, used in vertical shaft equipment, earth-moving drilling, wellbore lining, etc., can solve problems such as superelevation, super-wide pipe sections, and difficult pipe section transportation, and achieves the goal of improving durability and solving transportation difficulties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

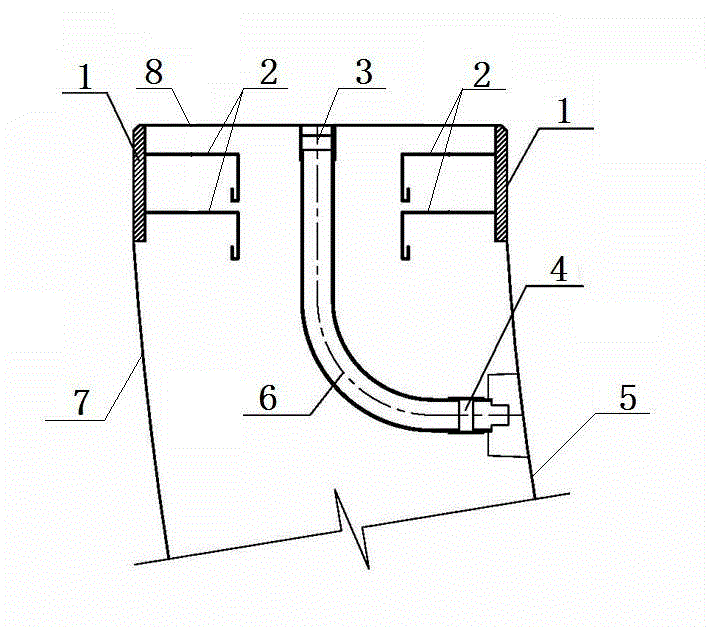

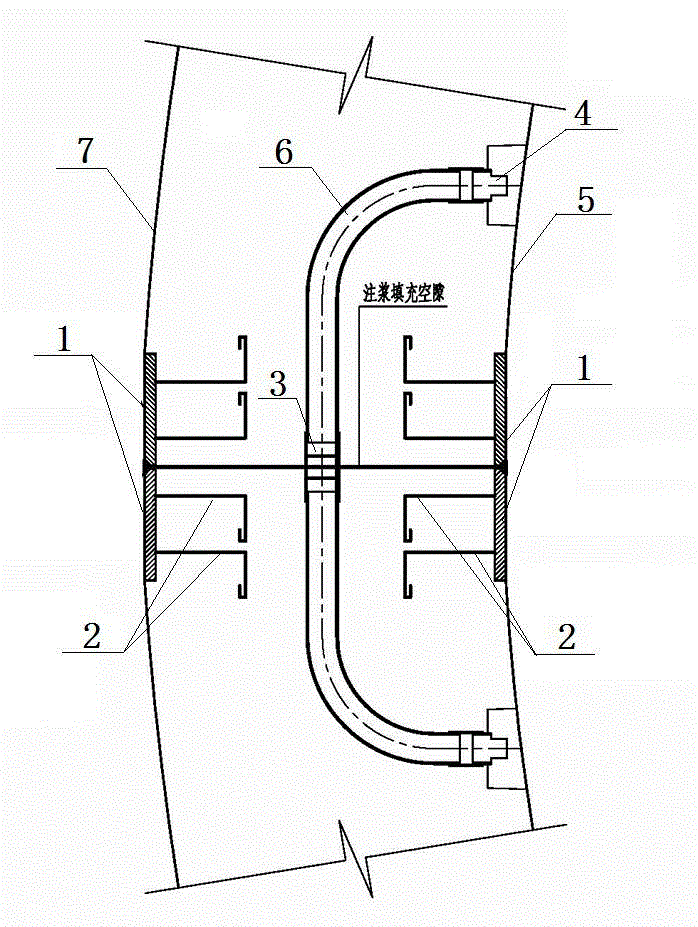

[0017] Embodiment: This embodiment specifically relates to an assembled pipe jacking segment structure and its assembly method, which is suitable for large-diameter pipe-jacking joints with an inner diameter of 3.5-5.0 m. For large-diameter pipe-jacking joints, it can be divided into 2- 3 segments, transported to the site and then assembled. The segment structure in this embodiment can form an effective connection between the pipe jacking segments, and form an integral pipe joint between the segments, so as to meet the stress and deformation requirements of the pipe jacking pipeline construction and use stage, and meet the use function of the pipeline and durability requirements.

[0018] Such as figure 1 As shown, embedded steel plates 1 are arranged at both ends of the inner arc surface 5 of the segment, and embedded steel plates 1 are also arranged at both ends of the outer arc surface 7 of the segment, and the end faces of each embedded steel plate 1 and the segment The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com