Hard Rock Tunneling Machine

A hard rock roadheader and machine body technology, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of easy safety accidents, low construction efficiency, low work efficiency, etc., to save charge and blasting links, simplify hardware Rock construction process, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

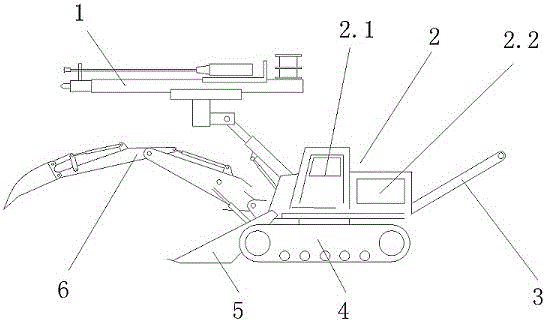

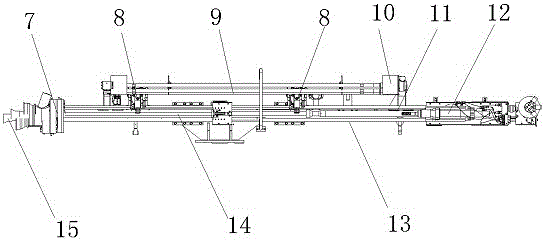

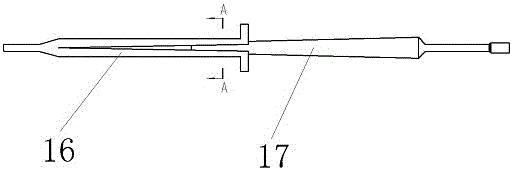

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the hard rock boring machine of the present invention includes a chassis traveling mechanism 4 and a body 2 provided with a cab 2.1 and a power system 2.2, and also includes a drilling splitting mechanism 1, an excavating mechanism 6, a shovel hopper 5 and a conveying mechanism 3, and the drilling The hole splitting mechanism 1 is arranged at the front upper part of the body 2, the excavating mechanism 6 is arranged at the front middle part of the body 2, and the shovel hopper 5 is arranged at the front lower part of the body 2, and the drilling splitting mechanism 1, the excavating mechanism 6 and the shovel hopper 5 are all hydraulically The cylinder is supported and connected with the body 2, the conveying mechanism 3 is arranged in the chassis running mechanism 4, the front en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com