Novel large-span assembly type hollow groined floor system

A large-span, prefabricated technology, applied in floors, building components, buildings, etc., can solve the problems of not being able to meet the needs of large bays, large floor beams, and affecting indoor net heights, achieving high rigidity and less formwork consumption , Increase the effect of indoor clear height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

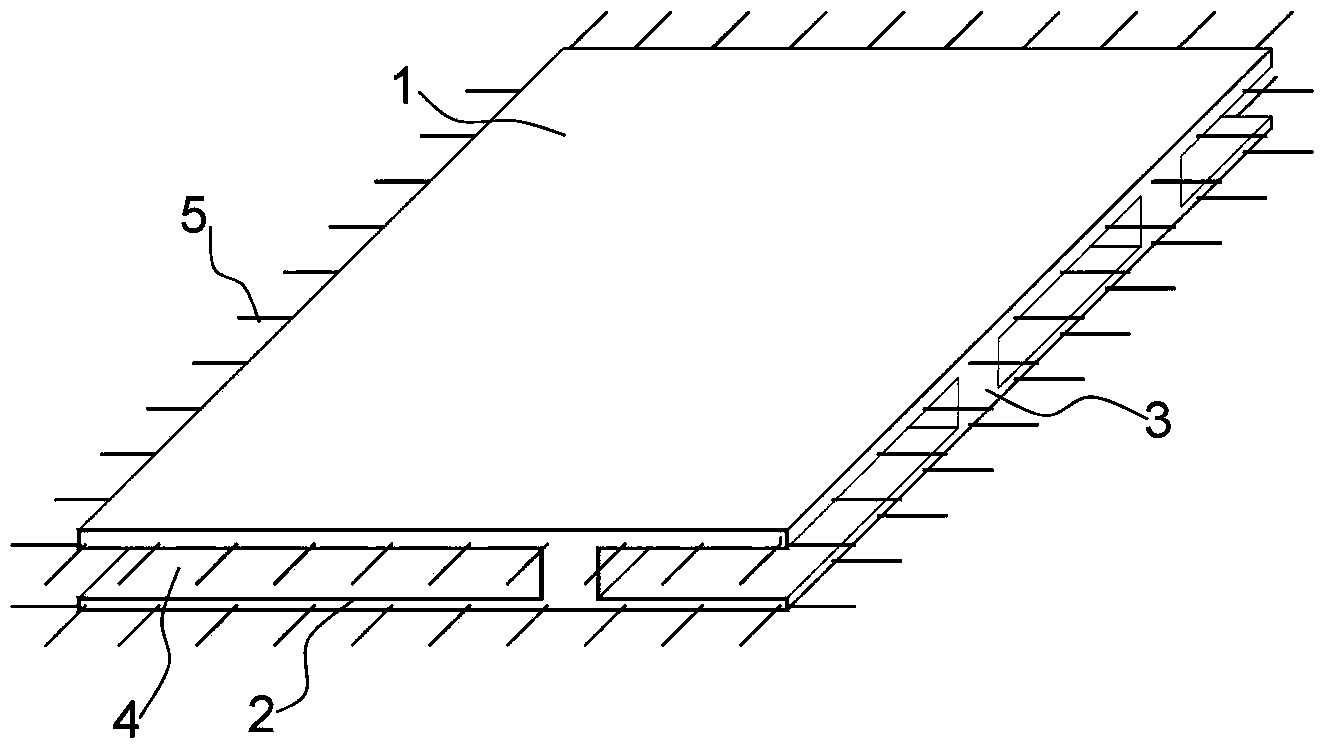

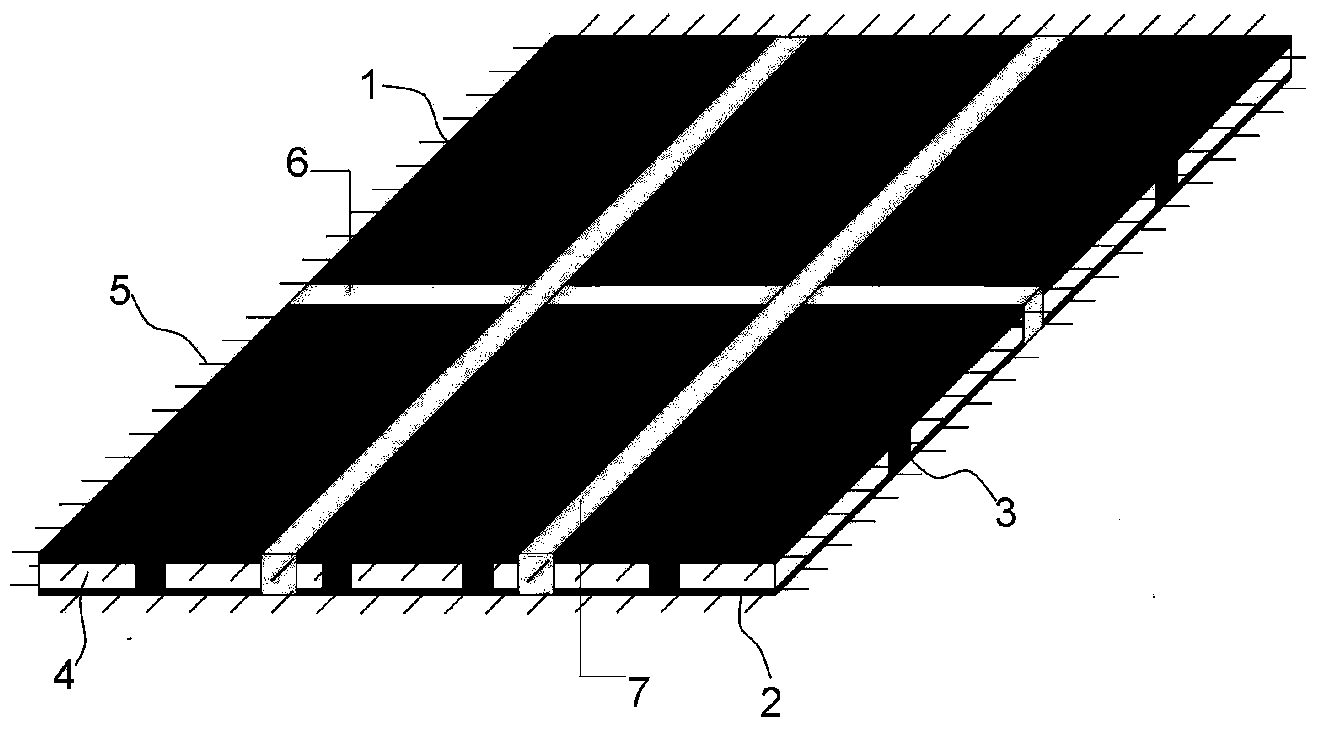

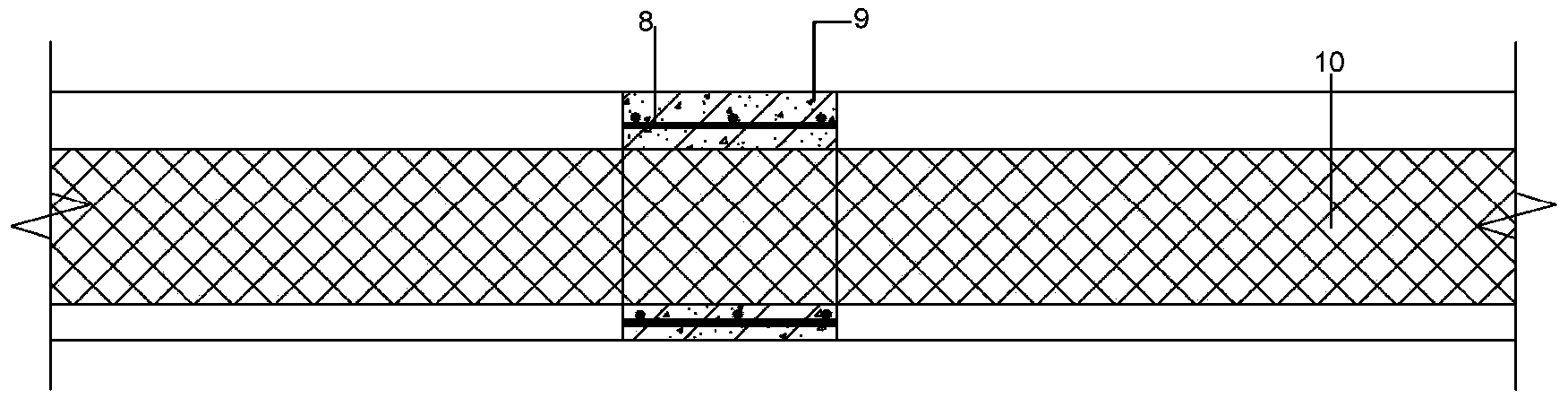

[0014] Such as figure 1 and figure 2 As shown, the novel large-span hollow self-insulating floor of the present invention adds a reinforced concrete floor on the basis of the traditional well-shaped floor to form a hollow floor structure with a flat bottom. Several prefabricated floor slabs are spliced and assembled through vertical and horizontal two-way concrete post-casting connection belts. A single floor slab has an integrally prefabricated top slab, bottom slab, and longitudinal and horizontal rib beams in the middle, and reserved steel bars protrude around the slab.

[0015] The prefabricated floor slab includes a top slab 1, a bottom slab 2, a number of well-shaped intersecting rib beams 3, and thermal insulation and sound insulation fillers 4; The directions are arranged at equal distances, and the thermal insulation and sound insulation fillers 4 are arranged between the rib beams 3 and fill up the gaps between the rib beams 3 .

[0016] The top slab 1, bottom s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com