High-brightness holographic anti-counterfeiting transfer coating and preparation method thereof

A holographic anti-counterfeiting and transfer coating technology, which is applied in camouflage coatings, coatings, etc., can solve the problem of solvent resistance sacrifice, etc., and achieve the effects of wide molding range, wide gravure printing adaptability, and excellent leveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0043] The following examples relate to a high-gloss holographic anti-counterfeiting transfer coating and a preparation method thereof, said method comprising the steps of:

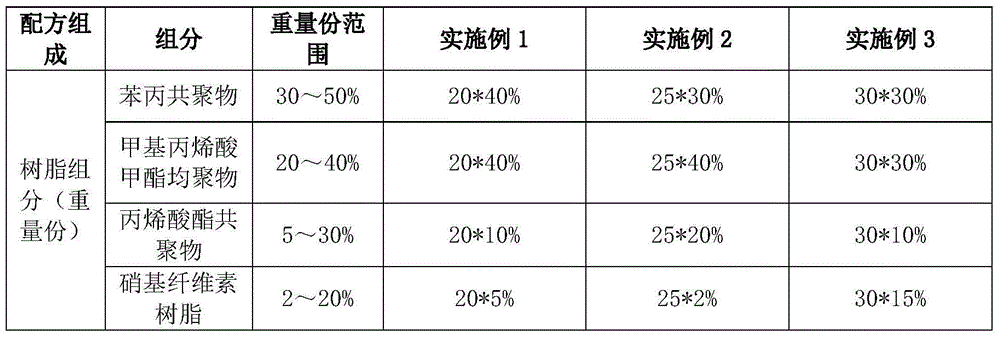

[0044] (1) Calculate and weigh the resin components according to formula table 1:

[0045] (2) Put the solvent part in the reaction kettle, turn on the stirring device to stir evenly and heat to 40-60°C;

[0046] (3) Put the resin component into the reactor, control the stirring rate to 600-800rpm, and dissolve for 3-5 hours until the resin component is completely dissolved (no solid particles remain);

[0047] (4) After the resin components are completely dissolved, put the additives into the reaction kettle, control the stirring speed at 800-1200rpm and stir for about 30 minutes until the additives are evenly dispersed, and obtain samples;

[0048] (5) Measure the solid content of the sample (according to the actual design value), and adjust the solid content of the sample to the design value by adding...

Embodiment 4-7

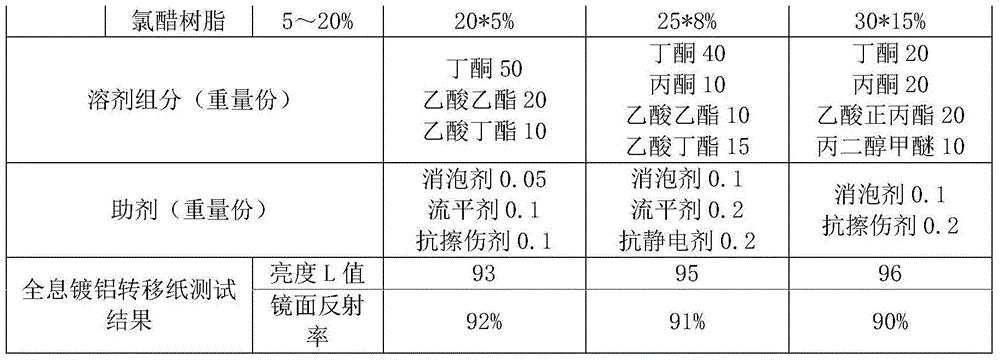

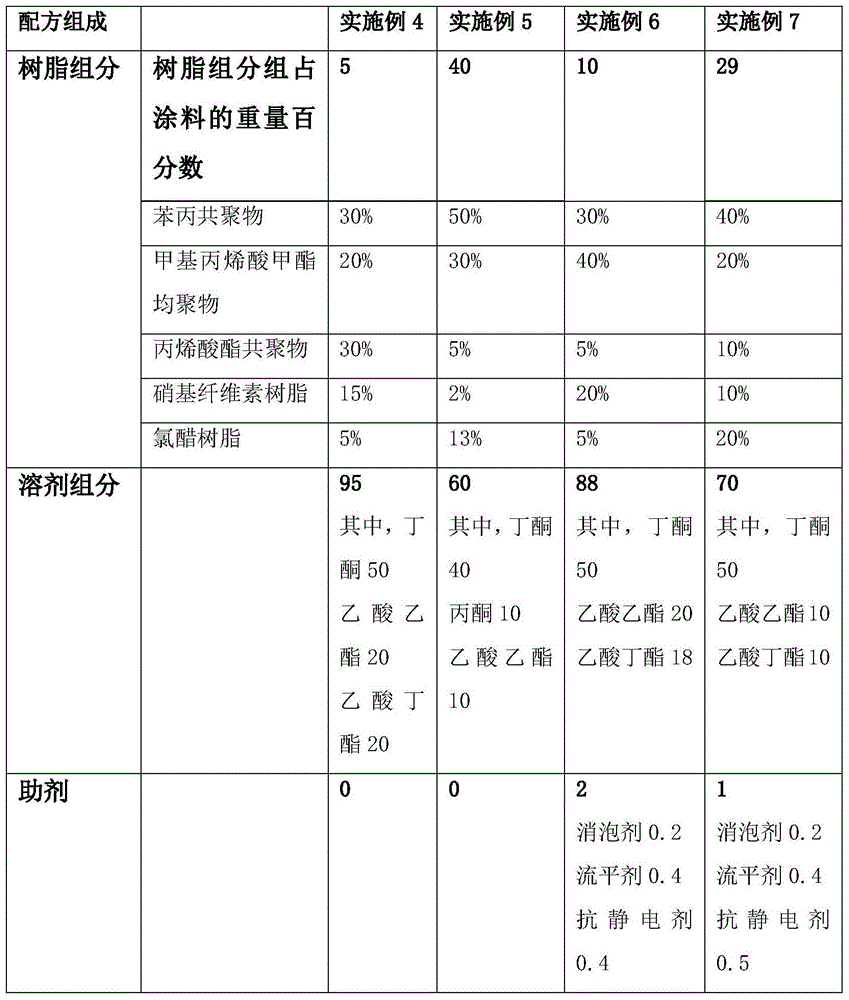

[0067] The following examples relate to high-brightness holographic anti-counterfeiting transfer coatings and preparation methods thereof. The methods are described in Examples 1-3. The components of the coatings in each example are shown in Table 2. In Table 2, the values are percentages by weight.

[0068] The resin component is composed of 5 kinds of resins, including the following components: styrene-acrylic copolymer, methyl methacrylate homopolymer; acrylate copolymer, nitrocellulose resin, vinyl acetate resin;

[0069] Wherein, the styrene-acrylic copolymer is a copolymer of styrene and acrylate monomers, the glass transition temperature ranges from 80 to 130° C., and the molecular weight is from 50,000 to 150,000.

[0070] The Tg range of the methyl methacrylate homopolymer is 100-130° C., and the molecular weight is 50,000-150,000.

[0071] The acrylate copolymer is a copolymer formed by the polymerization of methyl (meth)acrylate and ethyl (meth)acrylate, with a Tg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com