Technology for recovering and utilizing mother liquor generated during process of glycine production through chloroacetic acid method

A technology of glycine and chloroacetic acid, which is applied in the direction of ammonium halide, etc., can solve the problems of mother liquor pollution, low quality ammonium chloride, and low recovery rate, and achieve the effects of energy saving, high quality, and increased economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

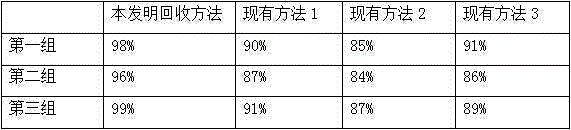

Image

Examples

Embodiment 1

[0033] A method of recycling the mother liquid during the production of glycine in the process of producing glycine, including the following process steps:

[0034] A. Concentration

[0035] First concentrate the mother liquid, get the mother liquid concentration solution and the precipted solid ammonium chloride;

[0036] B. Burning

[0037] The concentrated liquid concentration liquid obtained after concentration is transmitted into the incineration furnace for incineration, and the incineration temperature is controlled to 700 ° C;

[0038] C. Crystal

[0039] Crystal the gases generated by incineration are used in the cooling gymnomer, the crystalline temperature is controlled to 80 ° C, and the crystallization precipitated ammonium chloride.

Embodiment 2

[0041] A method of recycling the mother liquid during the production of glycine in the process of producing glycine, including the following process steps:

[0042] A. Concentration

[0043] First concentrate the mother liquid, get the mother liquid concentration solution and the precipted solid ammonium chloride;

[0044] B. Burning

[0045] The concentrated liquid concentration liquid obtained after concentration is transmitted into the incineration furnace for incineration, and the incineration temperature is controlled to 1000 ° C;

[0046] C. Crystal

[0047] Crystal the gases generated by incineration are used in the cooling gymnarian, and the crystalline temperature is controlled to 300 ° C, and the crystallization precipitated ammonium chloride.

Embodiment 3

[0049] A method of recycling the mother liquid during the production of glycine in the process of producing glycine, including the following process steps:

[0050] A. Concentration

[0051] First concentrate the mother liquid, get the mother liquid concentration solution and the precipted solid ammonium chloride;

[0052] B. Burning

[0053] The concentrated liquid concentration liquid obtained after concentration is transmitted into the incineration furnace for incineration, and the incineration temperature is controlled to 850 ° C;

[0054] C. Crystal

[0055] Crystal the gases generated by incineration are used in the cooling gymnomer, the crystalline temperature is controlled to 190 ° C, and the crystallization precipitated ammonium chloride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com