A kind of recycling process of mother liquor in the process of producing glycine by chloroacetic acid method

A technology of glycine and chloroacetic acid, which is applied in the direction of ammonium halide, etc., can solve the problems of low recovery rate, low quality of ammonium chloride, mother liquor pollution, etc., and achieve the effects of increasing economic benefits, good quality, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

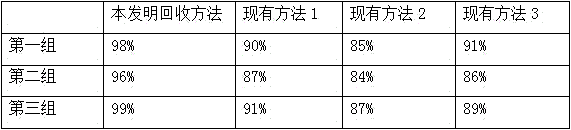

Image

Examples

Embodiment 1

[0033]A kind of recycling process of mother liquor in the process of producing glycine by chloroacetic acid method comprises the following process steps:

[0034] A. Concentration

[0035] Concentrate the mother liquor earlier to obtain the mother liquor concentrate and the separated solid ammonium chloride;

[0036] B. Incineration

[0037] Pass the concentrated mother liquor obtained after concentration into an incinerator for incineration, and the incineration temperature is controlled at 700°C;

[0038] C. crystallization

[0039] Pass the gas produced by incineration into a cyclone with cooling for crystallization, the crystallization temperature is controlled at 80°C, and ammonium chloride is precipitated by crystallization.

Embodiment 2

[0041] A kind of recycling process of mother liquor in the process of producing glycine by chloroacetic acid method comprises the following process steps:

[0042] A. Concentration

[0043] Concentrate the mother liquor earlier to obtain the mother liquor concentrate and the separated solid ammonium chloride;

[0044] B. Incineration

[0045] Pass the concentrated mother liquor obtained after concentration into an incinerator for incineration, and the incineration temperature is controlled at 1000°C;

[0046] C. crystallization

[0047] Pass the gas produced by incineration into a cyclone with cooling for crystallization, the crystallization temperature is controlled at 300°C, and ammonium chloride is precipitated by crystallization.

Embodiment 3

[0049] A kind of recycling process of mother liquor in the process of producing glycine by chloroacetic acid method comprises the following process steps:

[0050] A. Concentration

[0051] Concentrate the mother liquor earlier to obtain the mother liquor concentrate and the separated solid ammonium chloride;

[0052] B. Incineration

[0053] Pass the concentrated mother liquor obtained after concentration into an incinerator for incineration, and the incineration temperature is controlled at 850°C;

[0054] C. crystallization

[0055] Pass the gas produced by incineration into a cyclone with cooling for crystallization, the crystallization temperature is controlled at 190°C, and ammonium chloride is precipitated by crystallization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com