High-torque low-speed permanent magnet synchronous motor hoisting load on-line detection system and detection method

A permanent magnet synchronous motor, line detection technology, applied in the directions of load hanging components, transportation and packaging, safety devices, etc., can solve the problems of large weight sensor errors of cranes, dangerous installation and maintenance, unreliable weighing instruments, etc. Improve detection accuracy, eliminate potential safety hazards, and avoid the effects of inaccurate hoisting overload control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

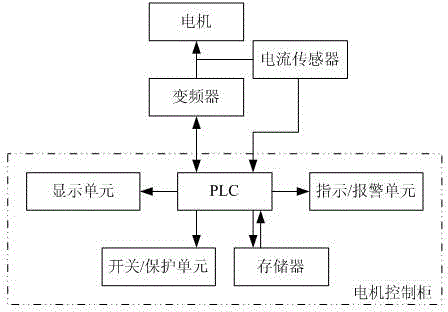

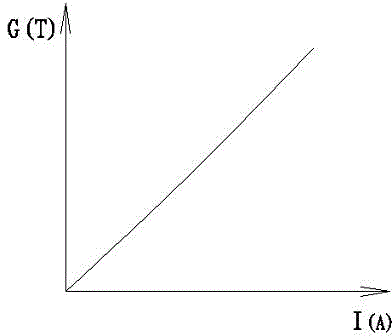

[0010] The invention provides an online detection method for the hoisting weight of a high-torque low-speed permanent magnet synchronous motor: obtain the current signal of the motor, use the current signal as a sensing signal reflecting the hoisting weight or calculate the hoisting weight of the motor according to the current signal Heavy data, the motor can be any permanent magnet synchronous motor including high torque low speed permanent magnet synchronous motor.

[0011] The current signal of the motor is a motor current input signal collected by a current sensor and / or a frequency converter current output signal obtained from a frequency converter used to supply power to the motor.

[0012] The current signal of the motor is a stator current signal of the motor.

[0013] The current threshold when the hoist is overloaded can be set. When the obtained current signal reaches or exceeds the set current threshold, the motor will be stopped and / or an overload alarm will be is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com