Control system applied to multipoint array flexible jig, and control method of control system

A flexible tooling and control system technology, applied in aircraft assembly, ground equipment, manufacturing tools, etc., can solve the problems of large shortest distance of support points, large volume of bent racks and saddles, increasing the number of drives and motors, etc., to reduce costs , reduce the volume, reduce the number of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

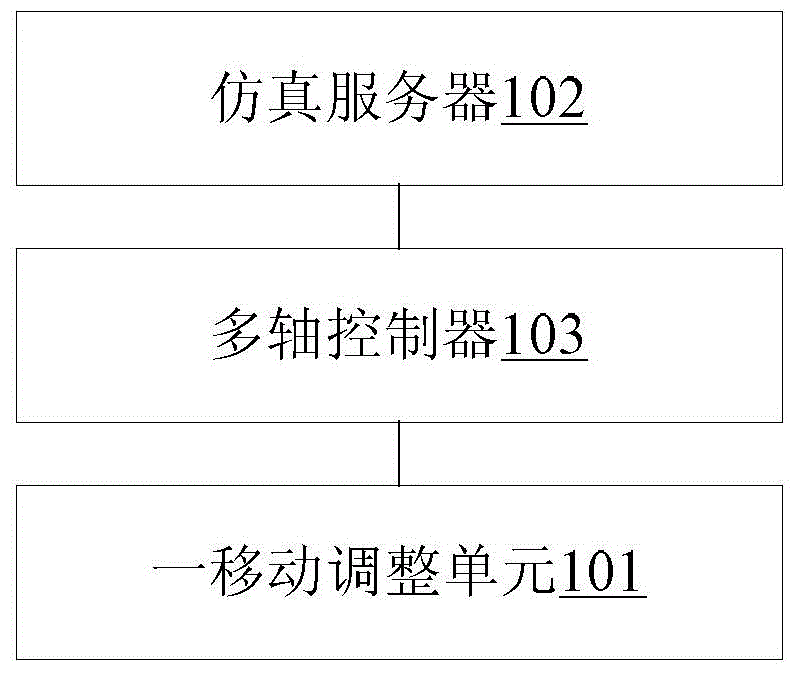

[0021] In the embodiment of the present invention, a control system applied to multi-point array flexible tooling is provided, such as figure 1 As shown, the system includes:

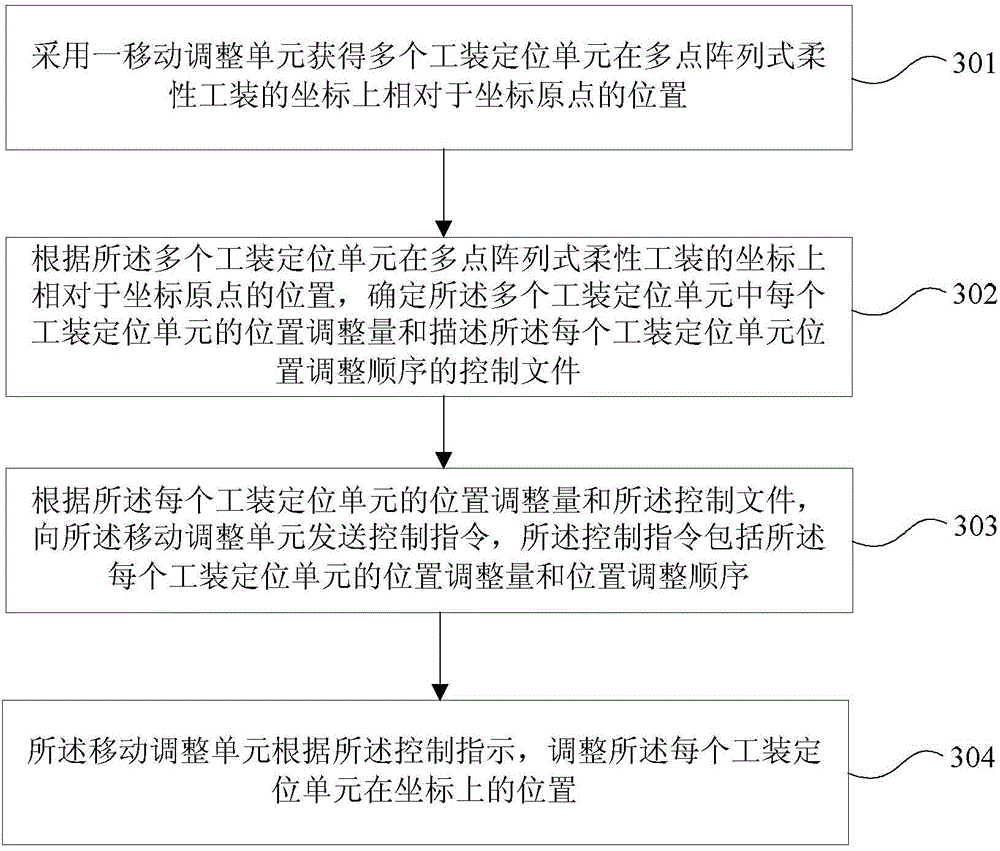

[0022] A movement adjustment unit 101, used to obtain the positions of multiple tool positioning units on the coordinates of the multi-point array flexible tooling relative to the origin of the coordinates;

[0023] The simulation server 102 is connected to the movement adjustment unit 101 through a multi-axis controller 103, and is used to determine the position of the multiple tool positioning units on the coordinates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com