Universal printing tool

A general-purpose, tooling technology, used in printing, printing presses, rotary printing machines, etc., can solve the problems of high tooling manufacturing and management costs, inability to achieve generalization, manual positioning errors, etc., to achieve high product consistency and reduce tooling. Manufacturing and management costs, the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

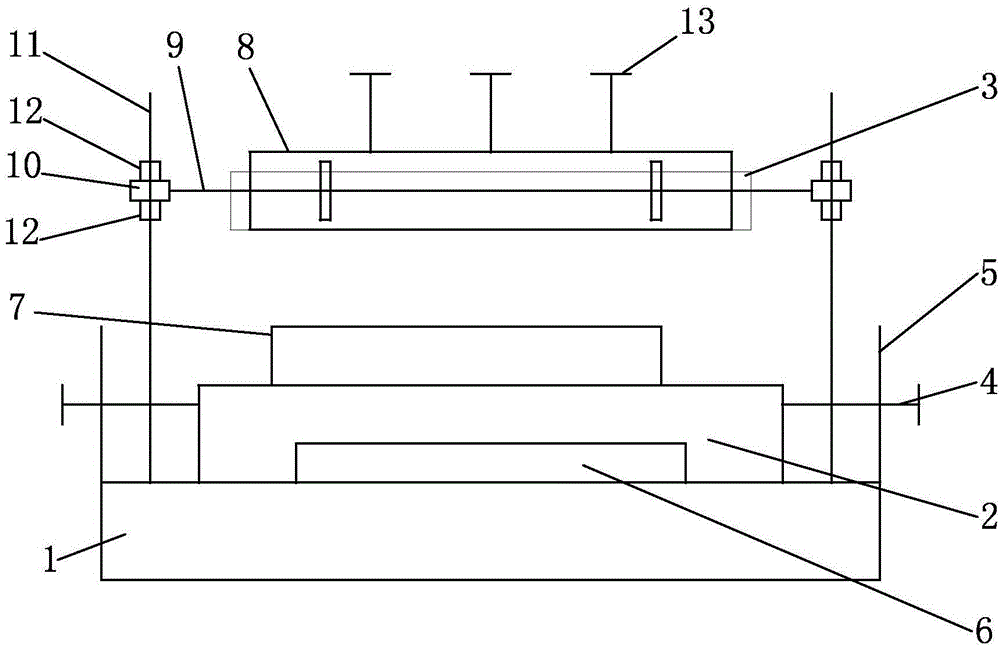

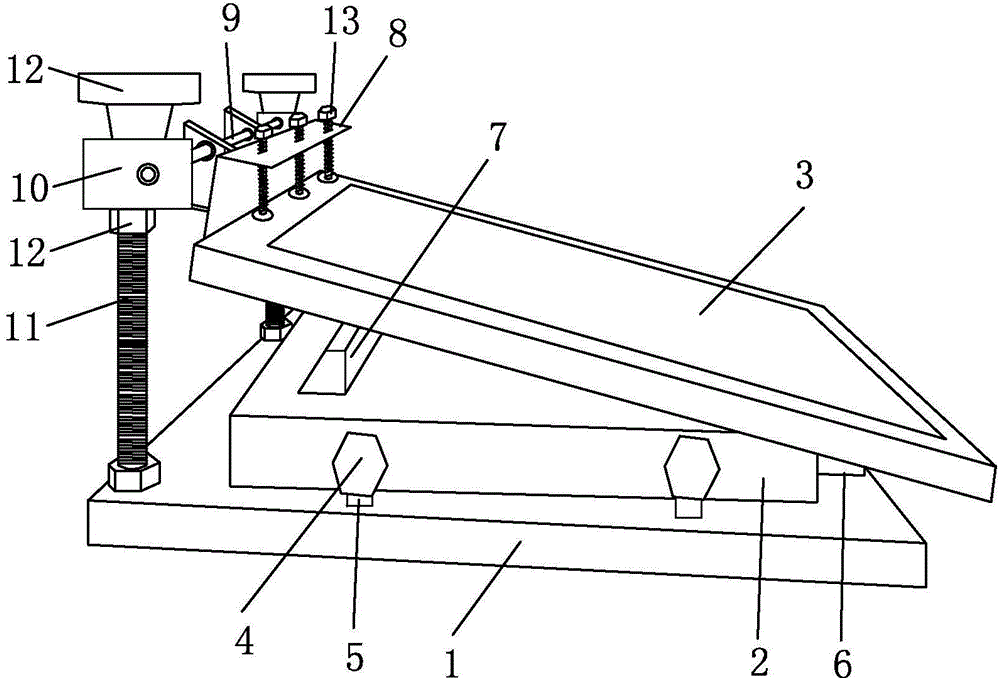

[0012] combine figure 1 , figure 2 As shown, a general-purpose printing tooling is mainly composed of a tooling base plate 1, a tooling fixing plate 2, a printing screen plate 3, a tightening bolt 4, a mounting lug 5, a fixing plate positioning baffle 6, a printing product positioning baffle 7, Stencil fixture 8, horizontal rod 9, mounting block 10, height adjustment screw rod 11, lock nut 12, fastening bolt 13 etc. are composed.

[0013] The tooling fixing plate 2 is placed above the tooling bottom plate 1, and top bolts 4 are symmetrically arranged on the left and right sides of the tooling fixing plate 2, and the top of the tooling bottom plate 1 is fixed with mounting lugs 5 equal in number and corresponding to the top tightening bolts 4 , the ends of the tightening bolts 4 horizontally pass through the corresponding mounting lugs 5 and then abut a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com