Loose tooling forging blank forming method of long-sheet complicated die forge piece

A technology of die forgings and thin plates, which is applied in the field of plastic forming of aviation products, can solve the problems of easy breakage at the cross-section transition, difficulty in forming structural die forgings, and many forging fires, so as to achieve good implementation effect and facilitate final forming , the effect of less forging fire times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for forming a tire die forging billet for a long thin plate complex die forging, the specific operation steps are as follows:

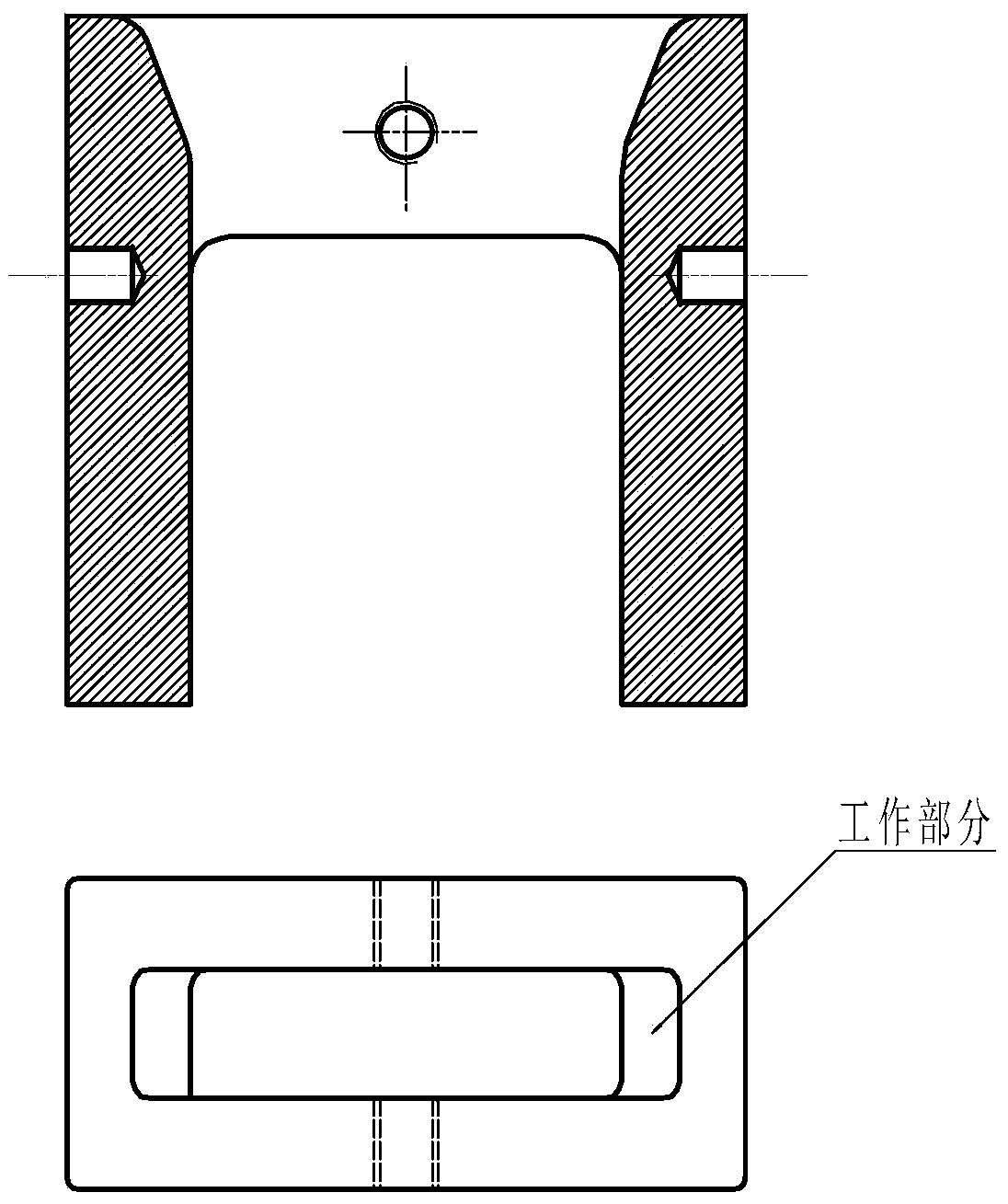

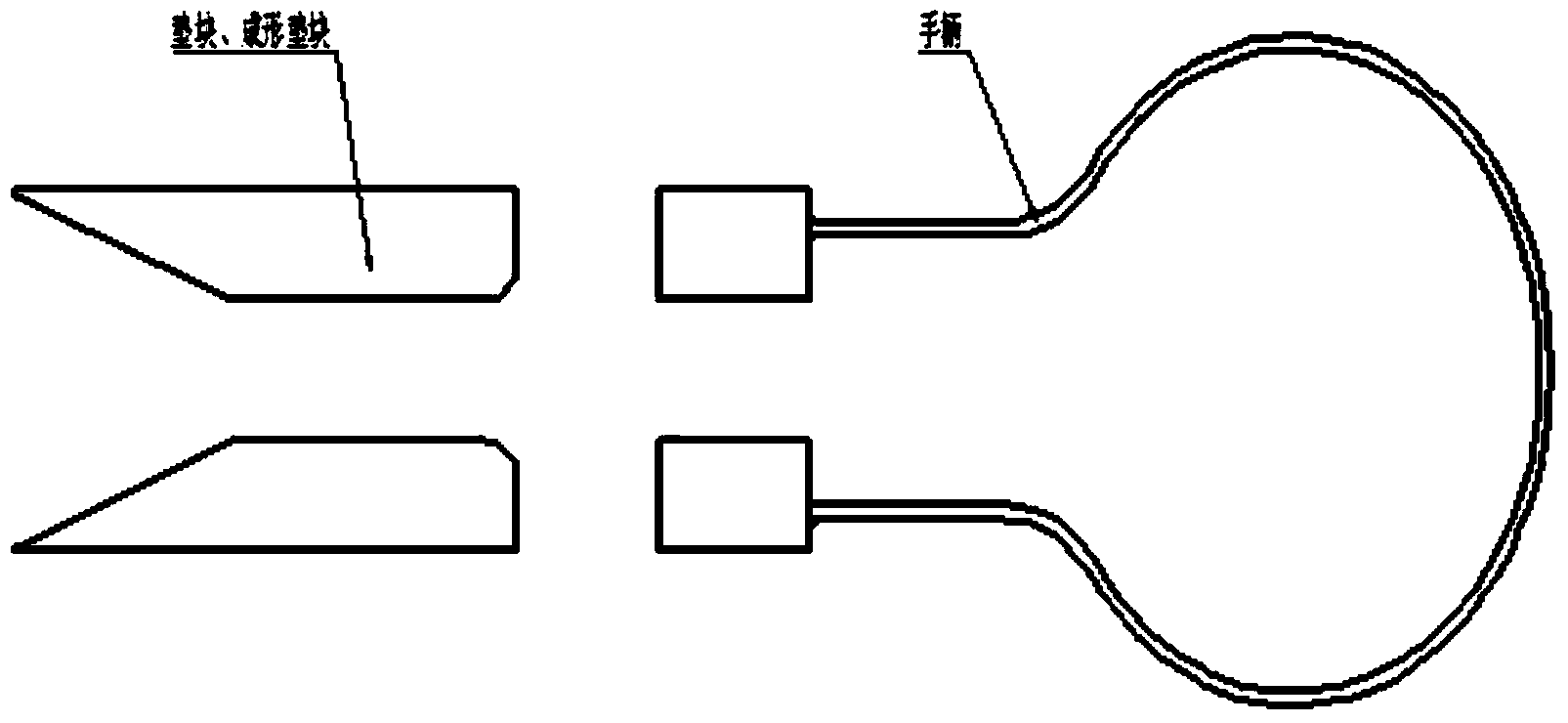

[0032] (1) Prepare the tire mold required for forging forming ( figure 2 ), block ( image 3 ), platen ( Figure 4 ) and tools such as pliers;

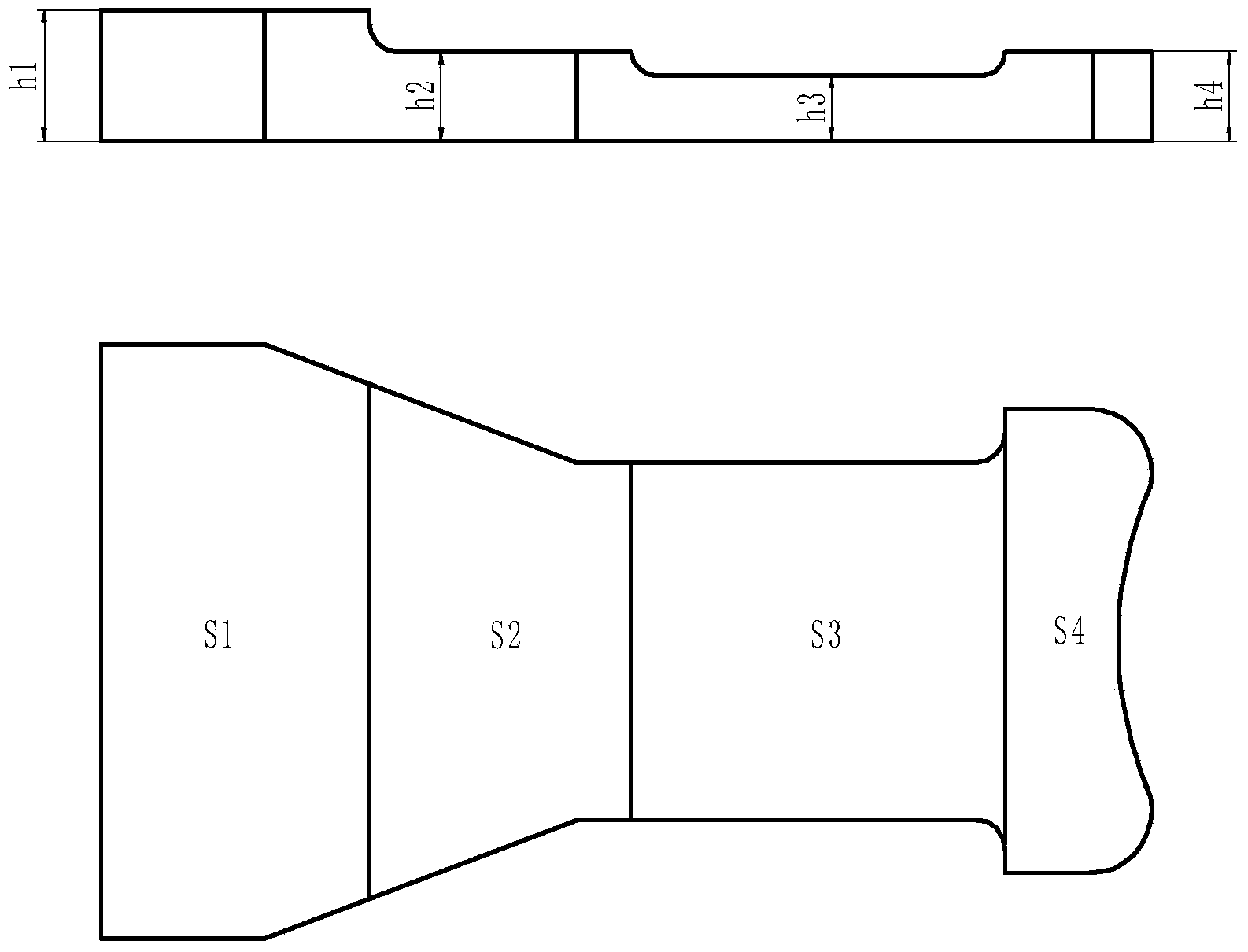

[0033] (2) Preheat the tire mold and tools to 200 ° C ~ 300 ° C, and heat the heated bar ( Figure 5 ) is placed on the flat anvil surface, and the processes of flattening, elongating and shaping are carried out along the radial direction of the bar to ensure Image 6 Medium and long square size requirements;

[0034] (3) Carry out size clamping along the length direction of the block, partially elongate the tail end, and use a semicircular pressing plate to make a dimple on the end face of the tail to ensure Figure 7 Shape and size requirements;

[0035] (4) Clamp the tire mold with the manipulator ( figure 2 ) is placed on the flat anvil of the forging hammer, and the Figure 7 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com