Green seaweed compound feed for penaeus monodon

A compound feed and seaweed technology, applied in animal feed, animal feed, applications, etc., can solve the problems of white rot of seaweed, marine environmental pollution, and unsatisfactory supply, achieve fast growth, improve survival rate, and achieve sustainable development Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

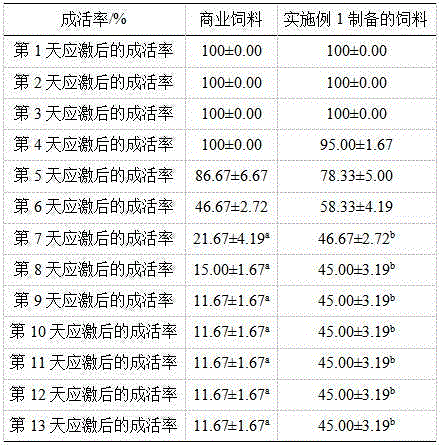

[0042] Prepare granular Penaeus monodon green seaweed compound feed by the raw material formula of embodiment 1 in table 1:

[0043] Table 1 The formula of embodiment 1~4 feed

[0044]

[0045] Wherein, the multivitamin used in embodiment 1 is made up of the composition of following mass parts: Vitamin D 3 0.06 parts, vitamin B 1 0.36 parts, vitamin B 2 0.72 parts, vitamin B 6 0.66 parts, vitamin B 12 0.002 parts, vitamin E acetate 1.65 parts, vitamin K 3 0.24 parts, vitamin B 3 1.44 servings, vitamin B 5 0.4 parts, 0.002 parts of biotin, 0.12 parts of folic acid, 3 parts of inositol, 50 parts of choline chloride with a purity of 50% and 41.346 parts of medium cellulose.

[0046] The used compound mineral salt of embodiment 1 is made up of the composition of following mass fraction: Ca(H 2 PO 4 ) 2 2H 2 O 50 parts, CaCO 3 21.5 parts, FeSO 4 ·7H 2 O 2 parts, MgSO 4 ·7H 2 12.4 parts of O, 9 parts of KCl, 4 parts of NaCl, ZnSO 4 ·7H 2 O 0.4 parts, CuSO...

Embodiment 2

[0056] Granular Penaeus monodon green seaweed compound feed was prepared according to the raw material formula of Example 2 in Table 1.

[0057] Wherein, the multivitamin used in embodiment 2 is made up of the composition of following mass parts: Vitamin D 3 0.06 parts, vitamin B 1 0.36 parts, vitamin B 2 0.72 parts, vitamin B 6 0.66 parts, vitamin B 12 0.002 parts, vitamin E acetate 1.65 parts, vitamin K 3 0.24 parts, vitamin B 3 1.44 servings, vitamin B 5 0.4 parts, 0.002 parts of biotin, 0.12 parts of folic acid, 3 parts of inositol, 50 parts of choline chloride with a purity of 50% and 41.346 parts of medium cellulose.

[0058] The used compound mineral salt of embodiment 2 is made up of the composition of following mass fraction: Ca(H 2 PO 4 ) 2 2H 2 O 50 parts, CaCO 3 21.5 parts, FeSO 4 ·7H 2 O 2 parts, MgSO 4 ·7H 2 12.4 parts of O, 9 parts of KCl, 4 parts of NaCl, ZnSO 4 ·7H 2 O 0.4 parts, CuSO 4 ·5H 2 O 0.35 parts, MnSO 4 ·H 2 O 0.34 part...

Embodiment 3

[0064] Granular Penaeus monodon green seaweed compound feed was prepared according to the formula of Example 3 shown in Table 1.

[0065] Wherein, the multivitamin used in embodiment 3 is made up of the composition of following mass parts: Vitamin D 3 0.06 parts, vitamin B 1 0.36 parts, vitamin B 2 0.72 parts, vitamin B 6 0.66 parts, vitamin B 12 0.002 parts, vitamin E acetate 1.65 parts, vitamin K 3 0.24 parts, vitamin B 3 1.44 servings, vitamin B 5 0.4 parts, 0.002 parts of biotin, 0.12 parts of folic acid, 3 parts of inositol, 50 parts of choline chloride with a purity of 50% and 41.346 parts of medium cellulose.

[0066] The used compound mineral salt of embodiment 3 is made up of the composition of following mass fraction: Ca(H 2 PO 4 ) 2 2H 2 O 50 parts, CaCO 3 21.5 parts, FeSO 4 ·7H 2 O 2 parts, MgSO 4 ·7H 2 12.4 parts of O, 9 parts of KCl, 4 parts of NaCl, ZnSO 4 ·7H 2 O 0.4 parts, CuSO 4 ·5H 2 O 0.35 parts, MnSO 4 ·H2 O 0.34 parts, KI 0.008 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com