Conveying device of solid strain inoculation machine

A technology of conveying device and solid strain, applied in the field of conveying device of strain inoculating machine, can solve the problems of affecting inoculation quality, difficulty in cleaning and disinfection, affecting operation efficiency, etc., and achieve safe and reliable production efficiency, easy control of density, and disinfection and sterilization. Bacteria thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

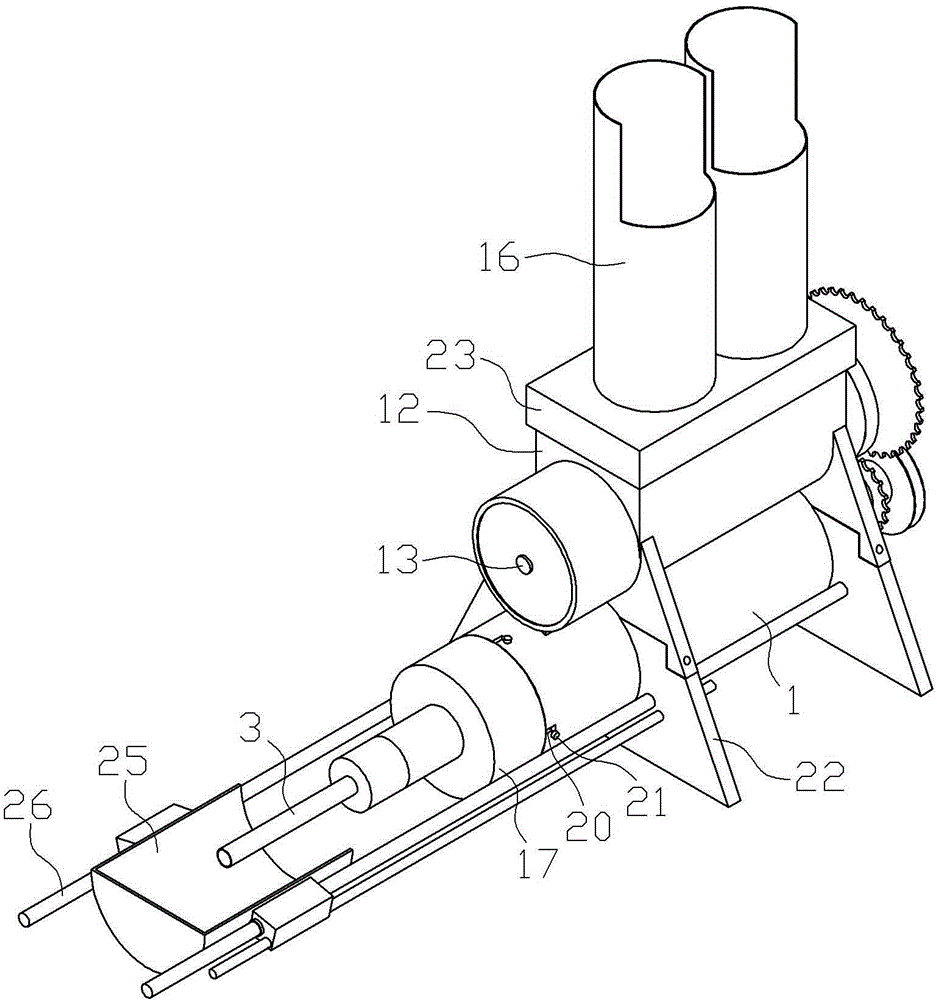

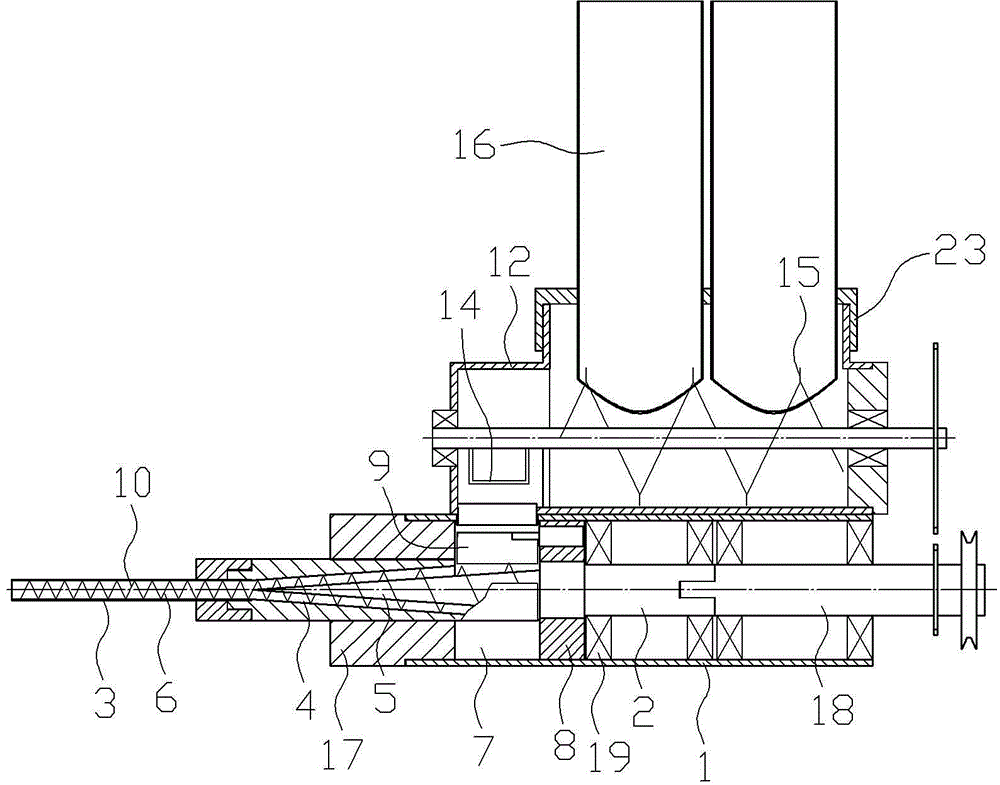

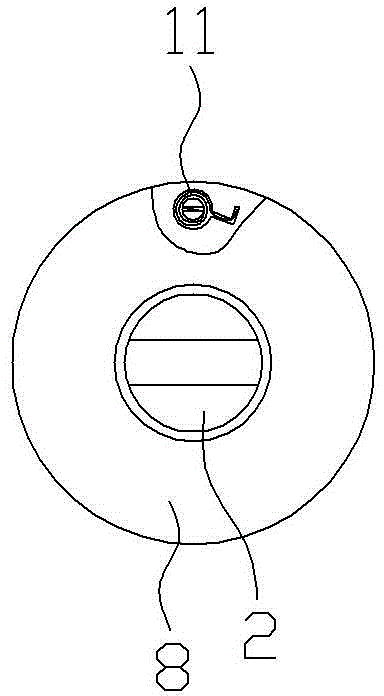

[0013] Such as Figures 1 to 3 As shown, the conveying device of the solid strain inoculation machine includes a strain crushing device and an inoculation feeding device. 1 and the feeding screw shaft 2 placed in the feeding cylinder 1. The front end of the feeding cylinder 1 is provided with a feeding tube 3, which is used to insert into the inoculation hole reserved in the bacteria bag. The feeding tube 3 and the feeding tube 1. It is connected by screw connection to facilitate disassembly and cleaning. The feeding cylinder 1 is provided with a tapered chamber 4 at the rear end of the feeding pipe 3. The thin end of the tapered chamber 4 is connected with the feeding pipe 3. The tapered chamber 4 The top opening of the thick end of the feeder is connected to the discharge end of the crushing device, and the feeding screw shaft 2 is provided with a conical helical section adapted to the shape of the conical cavity 4 of the feeding cylinder 1, and the conical helical section i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com