Station switching device of valve sealing performance test platform

A test platform and valve sealing technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, etc., can solve the problems of valve weight, handling, switching stations, and inconvenient sealing test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

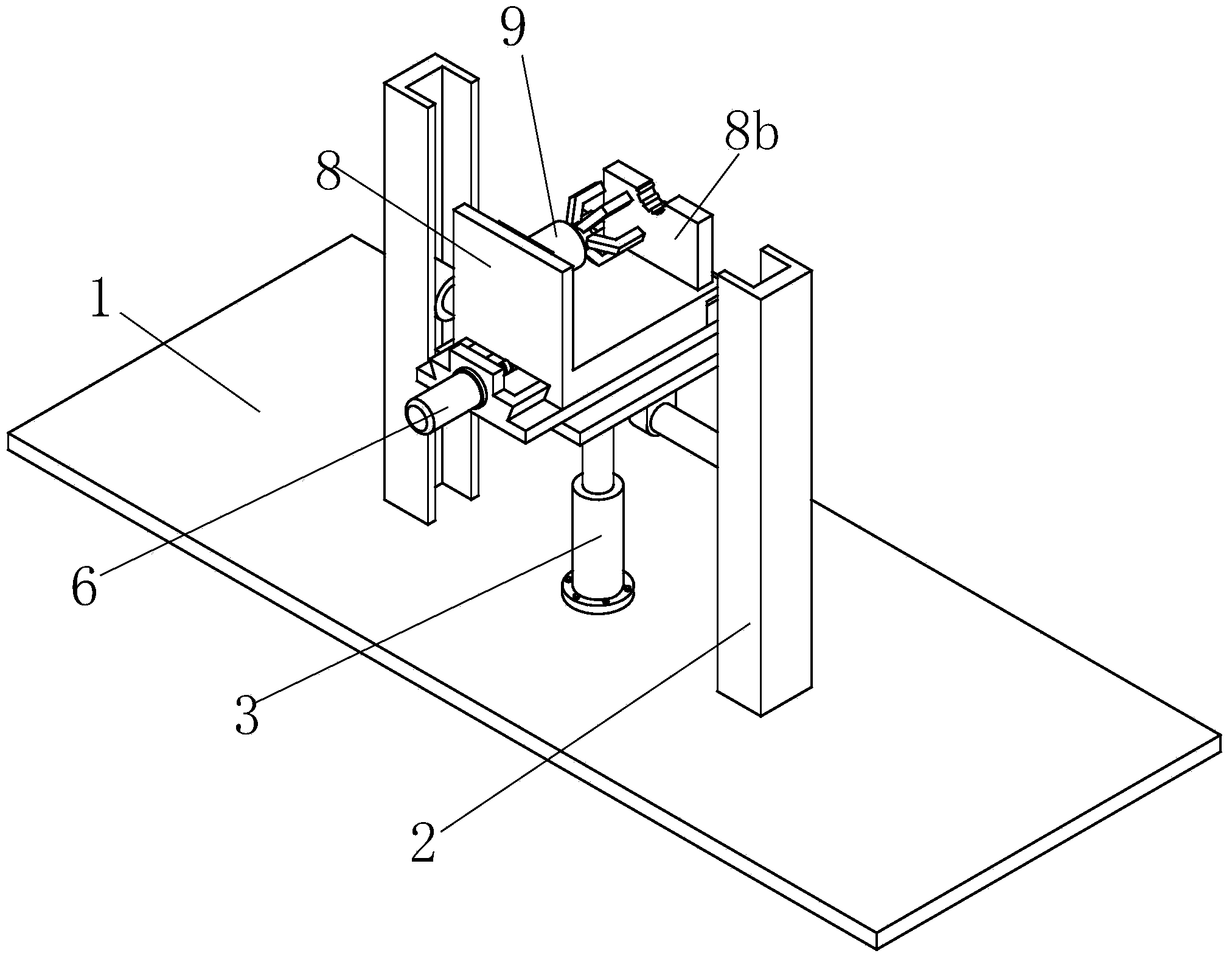

[0014] Such as Figure 1 to Figure 3 As shown, an indexing device for a valve sealing test platform includes a base 1, a guide frame 2, a height adjustment cylinder 3, an abutment 5, a sliding column 4, a sliding table 8, a positioning motor 6, a screw 7, an indexing The motor 9 and the claw plate 10, the guide frame 2 is fixed on the upper part of the base 1, the sliding column 4 is arranged laterally between the guide frames 2, and the sliding column 4 is slidably fitted with the guide frame 2, the The abutment 5 is fixed on the middle and upper part of the sliding column 4, and the abutment 5 is arranged horizontally. Parallel, the front end of the lead screw 7 is connected with the positioning motor 6, the rear end of the lead screw 7 is connected with the rear part of the base 5 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com