A self-confirming magnetic liquid micro-pressure differential sensor

A micro differential pressure sensor and magnetic liquid technology, applied in the field of sensors, can solve the problems of inability to evaluate the working state of the sensor, and the failure of the micro differential pressure sensor cannot be eliminated in time, so as to achieve the effect of ensuring safe production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] to attach figure 1 , 2 The present invention will be further described for the specific embodiment:

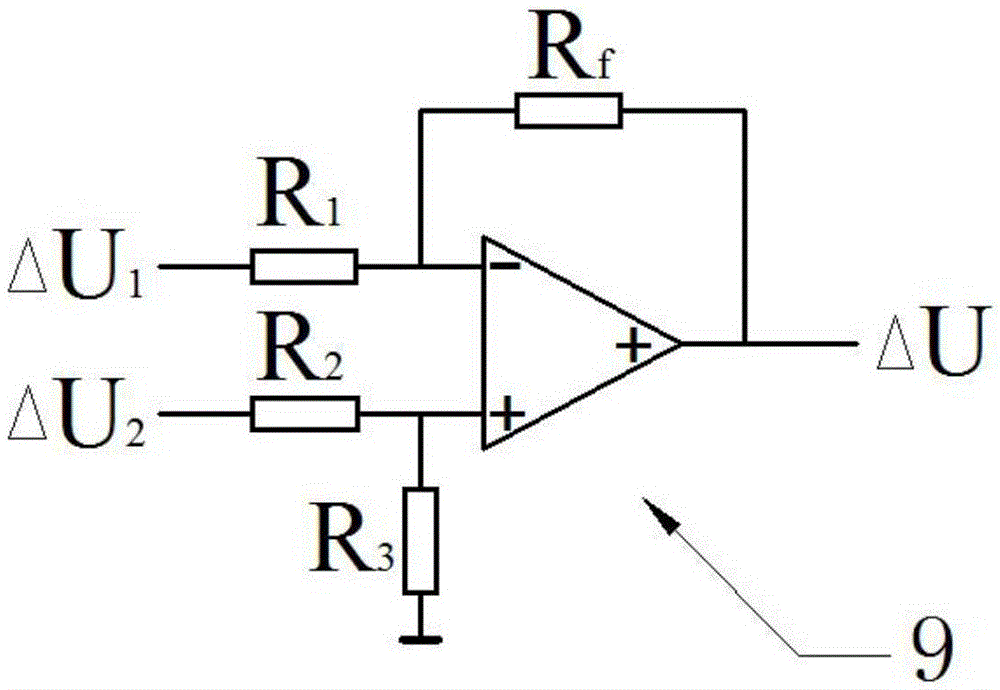

[0022] A self-confirming magnetic liquid micro pressure difference sensor, the device includes: a transparent glass tube 1, a first cylindrical hollow permanent magnet 2-1, a second cylindrical hollow permanent magnet 2-2, and a first induction coil 3-1 , second induction coil 3-2, first magnetic liquid ring 4-1, second magnetic liquid ring 4-2, first cylindrical permanent magnet 5-1, second cylindrical permanent magnet 5-2, iron core 6 , the first limiter 7-1, the second limiter 7-2, the infrared distance sensor 8, the subtractor 9.

[0023] Connections between the parts of the device:

[0024] Wind high-strength enamelled copper wires evenly, symmetrically, and with equal turns to both ends of the transparent glass tube 1 to form the first induction coil 3-1 and the second induction coil 3-2 respectively; the first cylindrical hollow permanent Magnet 2-1 and first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com