Aircraft engine tail profile measurement device and method based on machine vision

A technology for aircraft engine and contour measurement, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of slow measurement speed, high tail temperature, large size, etc., and achieve the effect of improving accuracy and increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

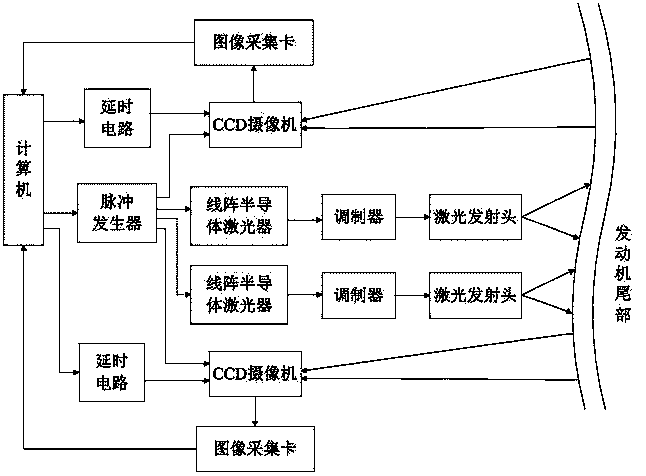

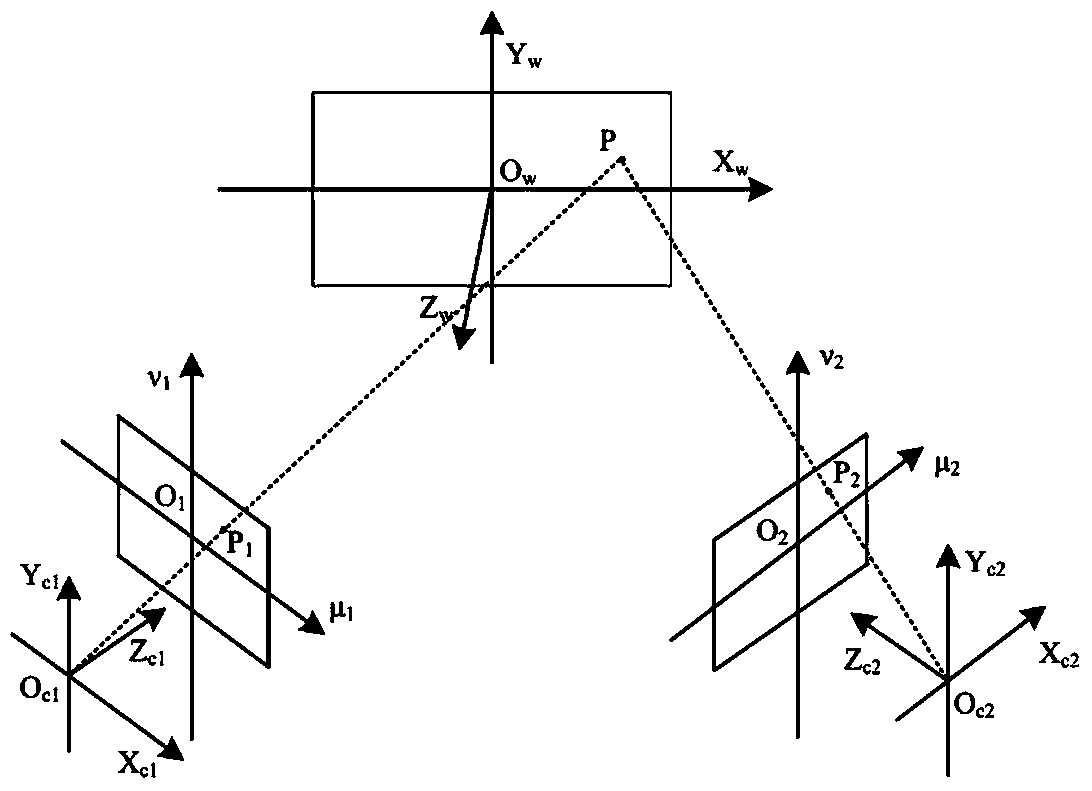

Method used

Image

Examples

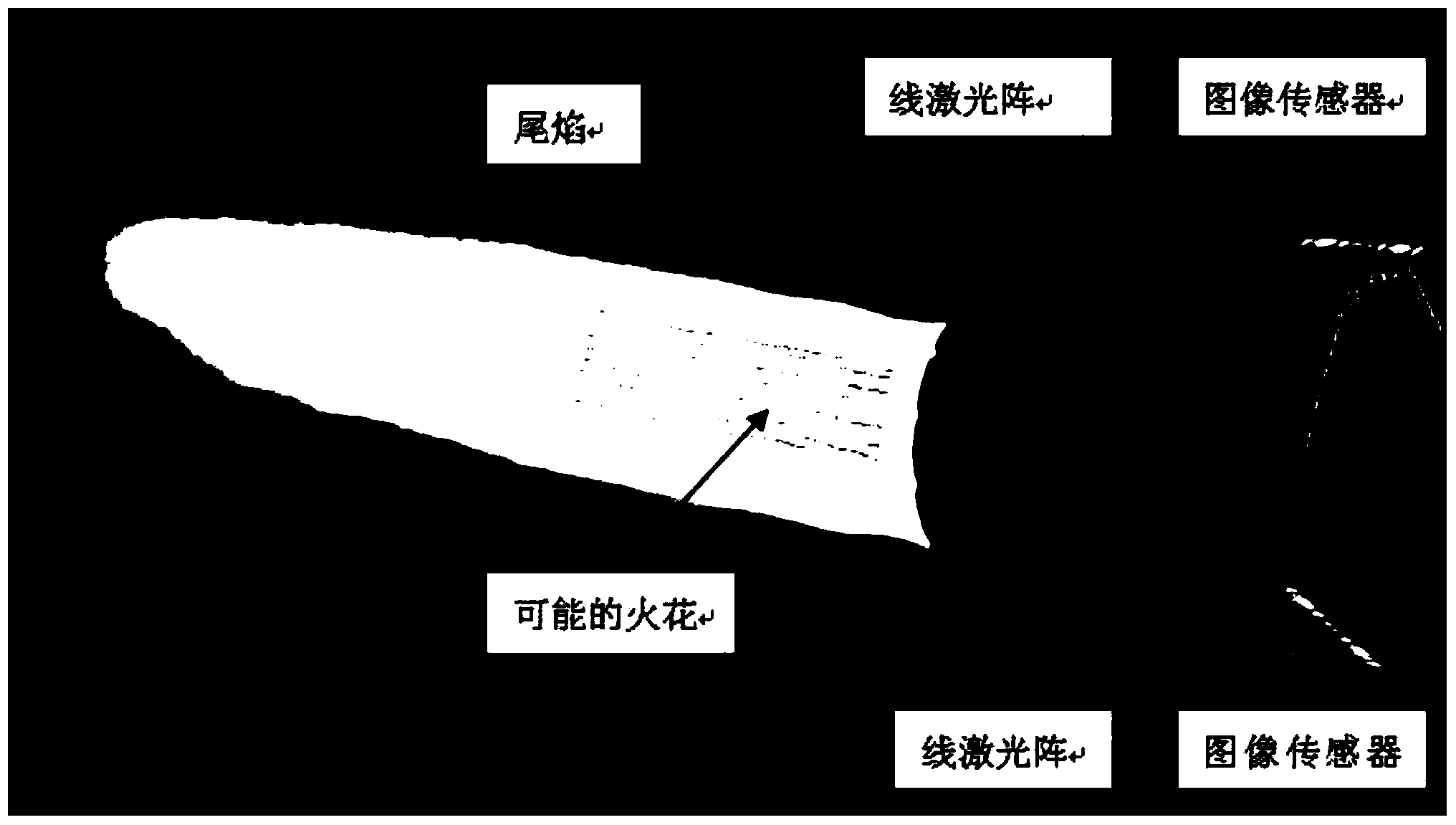

Embodiment Construction

[0041] For the interference of strong background light at the tail of the engine, we used laser lock-in imaging technology. The basic principle of lock-in imaging is the weak signal detection principle widely used in phase-locked loops, including two processes of multiplication and low-pass filtering. For locked imaging of digital images, multiplication and low-pass filtering become digital multiplication and digital low-pass filtering operations, which can be realized by software. Lock-in imaging can generally extract weak image signals that are more than 200 times lower than noise; while optical filters can filter out about 90% of background light. The image acquisition technology that combines optical filtering and digital lock-in imaging is called laser lock-in imaging technology. This technology has unparalleled ability to suppress background light. Experiments have shown that when the intensity of the background light is 104 times greater than that of the target scatte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com