Screw transmission hoist with cylinder body and push rod

A technology of screw drive and hoist, which is applied in sea area engineering, construction, barrage/weir, etc. It can solve the problem of screw affecting building structure or landscape, operation management, maintenance difficulties, and slow opening and closing speed of screw hoist, etc. problems, to achieve the effect of strong anti-corrosion and anti-fouling ability, good lubrication and protection conditions, and strong rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

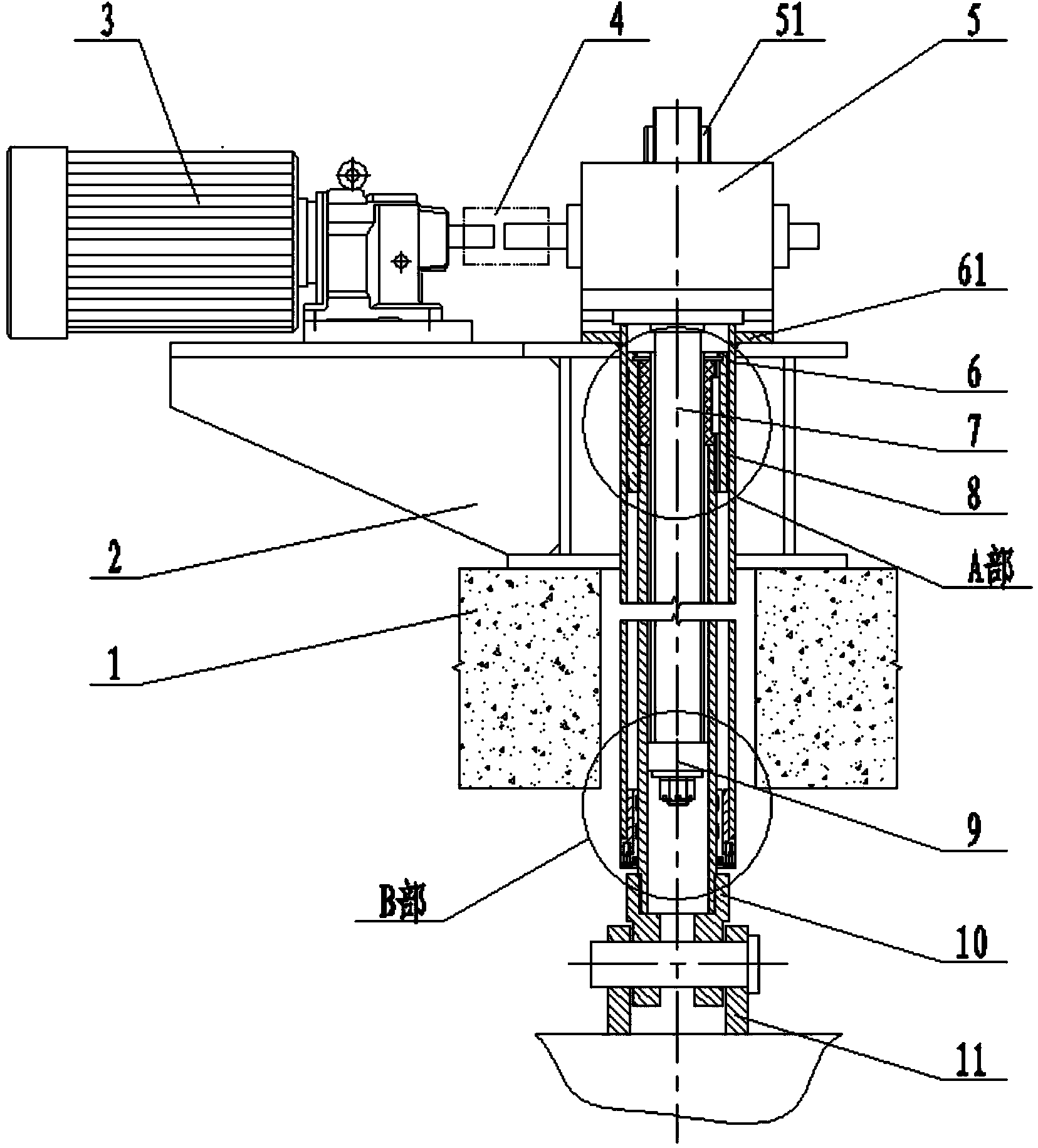

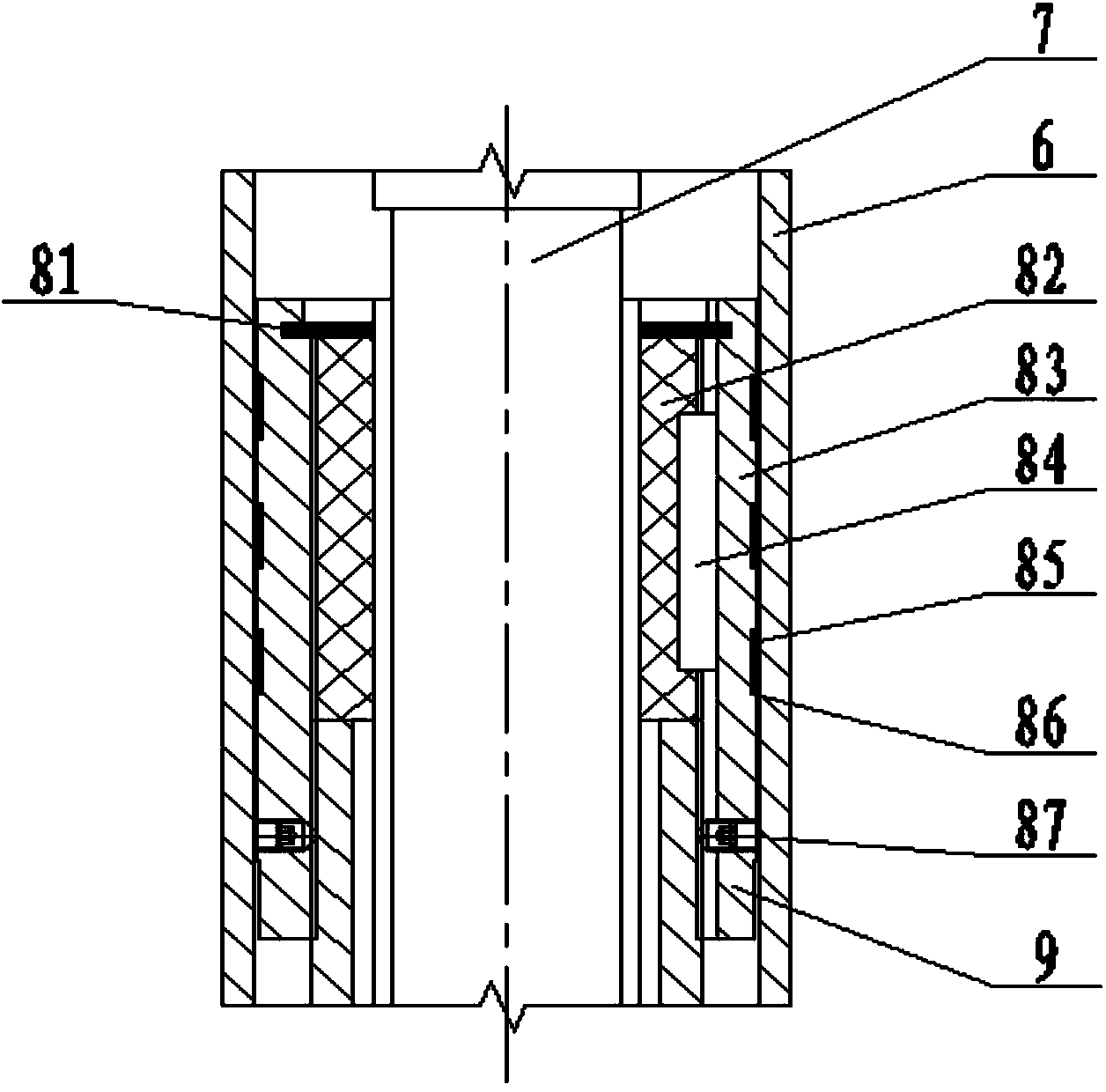

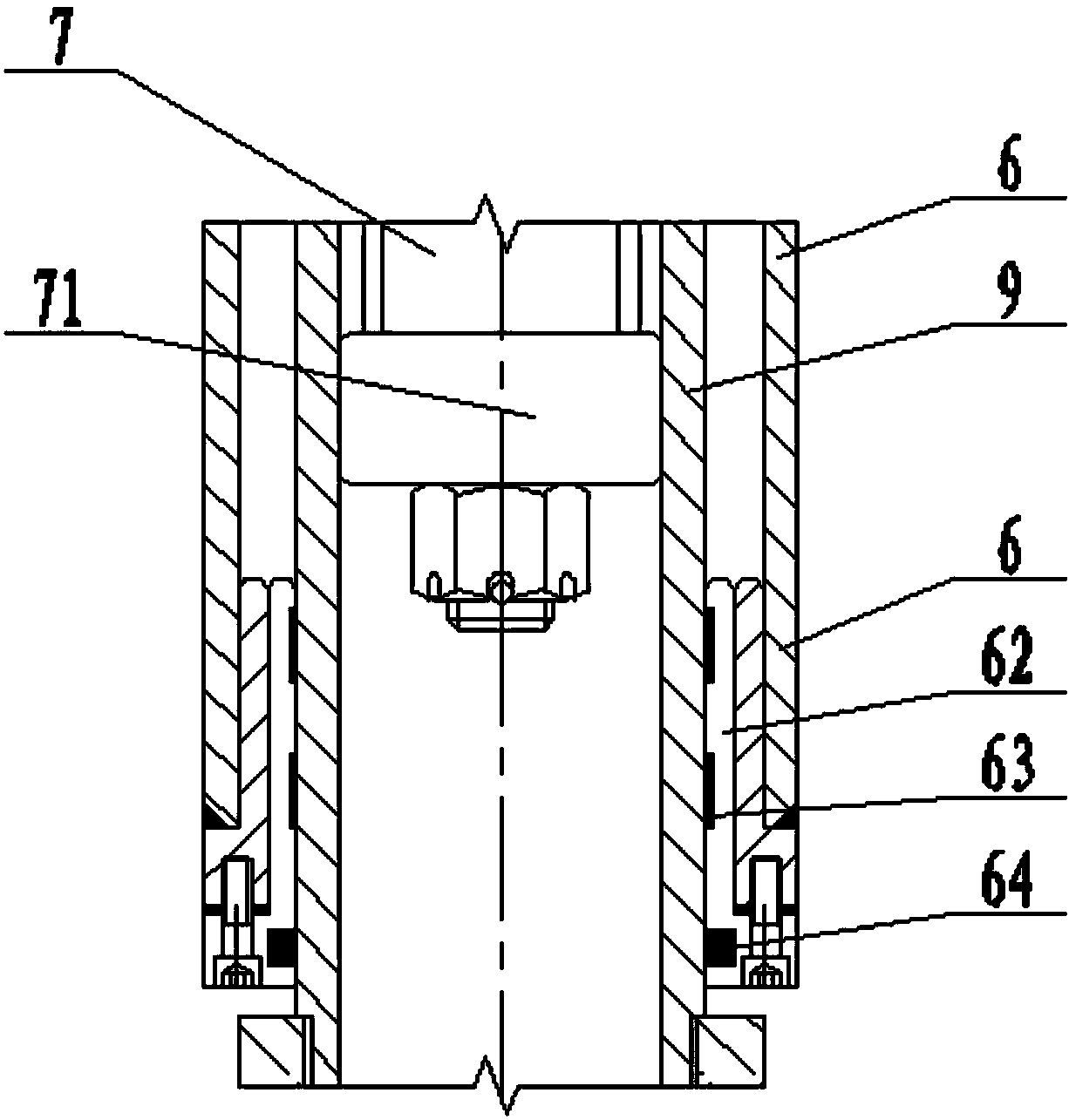

[0018] Such as figure 1 As shown, the present invention is mainly made up of frame 2, reduction motor 3, shaft coupling 4, hollow shaft reducer 5, cylinder body 6, screw rod 7, load-bearing nut 8, hollow push rod 9 and suspension head 10; frame 2 is fixed on the concrete foundation 1, the cylinder body 6 and the hollow shaft reducer 5 are vertically fixed on the frame 2 after being connected by the cylinder body flange 61; the hollow shaft reducer 5 and the reduction motor 3 lying on the frame 2 Connected through the coupling 4; the upper end of the screw rod 7 passes through the hollow shaft reducer 5 and is locked vertically in the center of the cylinder body 6 after being locked by the lock nut 51; the load-bearing nut 8 and the hollow push rod 9 are connected as one and arranged in Vertically move up and down between the screw mandrel 7 and the inner wall of the cylinder body 6;

[0019] The type of the hollow shaft reducer 5 can be a worm gear reducer or a bevel gear red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com