Full width cloth support device of rapier jacquard loom

A jacquard and loom technology, used in auxiliary equipment for weaving, textiles, textiles and papermaking, etc., can solve the problem of large loom vibration, large warp fluctuations, aggravated fabric width and weft shrinkage, fabric slack and loose warp, etc. The problem is to avoid the weft shrinkage, the large holding angle, and the warp skew.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

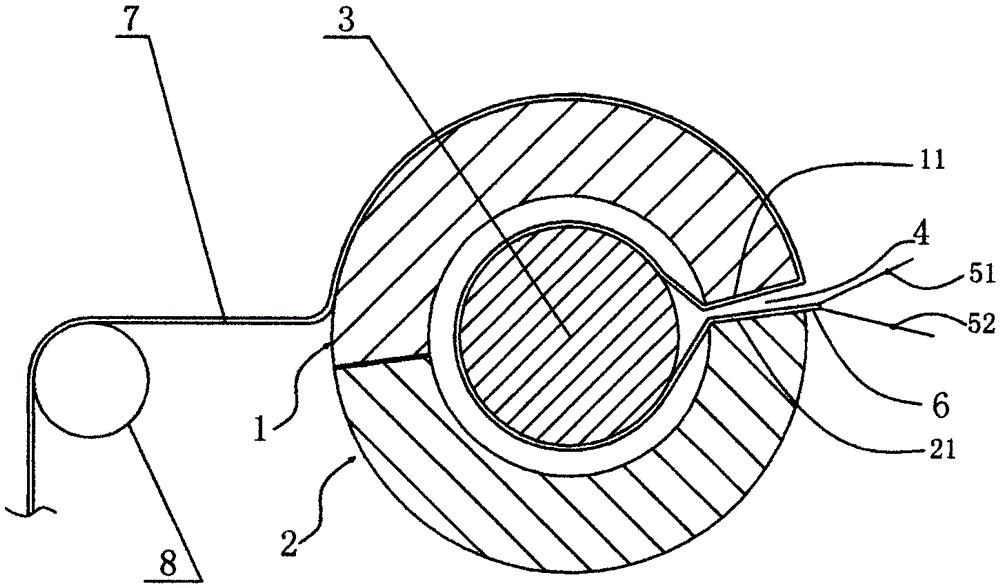

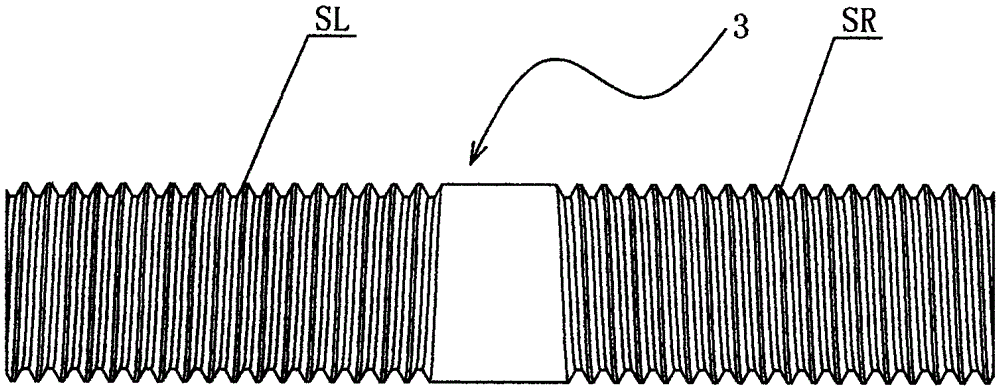

[0014] The full-width cloth support device of the rapier jacquard loom includes a single semicircular cover plate 1, a single semicircular support plate 2 and a single strip movably arranged between the cover plate 1 and the support plate 2. Screw rod 3, said screw rod 3 is formed with two continuous threads with the same pitch and opposite helical directions respectively inclined toward the rod end from the middle position of the rod, and the fabric inlet and outlet 4 is formed between the front end 11 of the cover plate and the front end 21 of the support plate.

[0015] The fabric 7 is continuously interwoven with the upper warp yarn 51 and the lower warp yarn 52. With the weaving movement of the rapier jacquard loom, the fabric formed at the weaving fell 6 continues to move into the front end 21 of the support plate, and then wraps the screw in the moving state. 3 and move out the front end 11 of the cover plate to be rolled away from the full-width cloth support device of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com