Large steel member transporting device on construction site

A technology of transportation devices and steel components, which is applied in the direction of vehicles used to carry long goods, can solve the problems of increasing construction costs, and achieve the effects of saving construction costs, simple structure, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

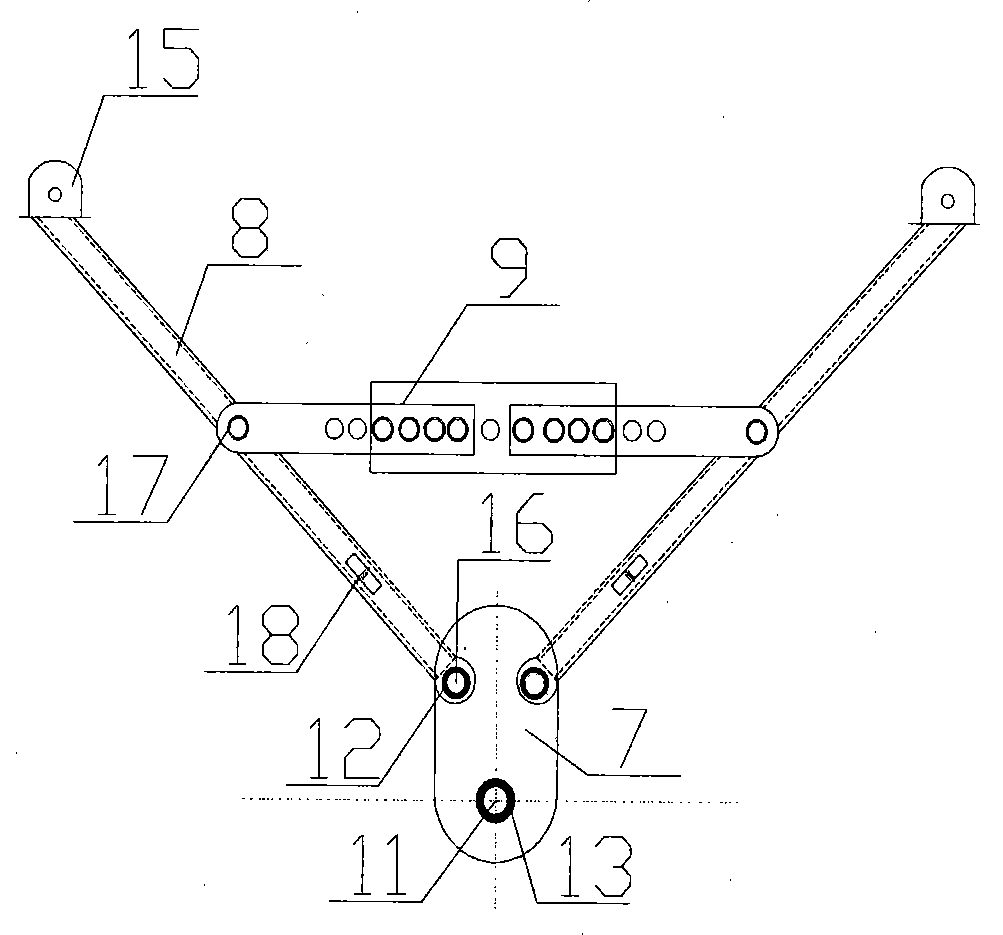

[0011] Example 1: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , The present invention relates to a large-scale steel component transportation device on a construction site, including a rubber wheel bracket 1 and a connecting tripod 2 . It is characterized in that: the rubber wheel bracket 1 is composed of two rubber wheels 3 and a steel beam 4. Bearings 5 are arranged at both ends of the steel beam 4 to be connected with the two rubber wheels 3 respectively to form a bracket and a walking system; the connecting tripod 2 is composed of A connecting plate 7, two horizontal connecting rods 8, one horizontal support rod 9 and two vertical connecting rods 10 are composed; the connecting plate 7 is provided with three pin shaft holes 11, two of which are respectively connected with two pin shafts 12. The horizontal connecting rod 8 is connected, and the other hole is connected with the tractor 14 by the pin 13; the two horizontal connecting rods 8 are each prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com