Processing method of ring screw hole on mold

A processing method, the technology of lifting ring screw, which is applied in the processing field of the screw hole of the lifting ring on the mold, can solve the problems such as the main shaft swings violently, the lifting ring is broken, and cannot meet the needs of customers, so as to shorten the processing cycle, improve the force strength, reduce the The effect of rework rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

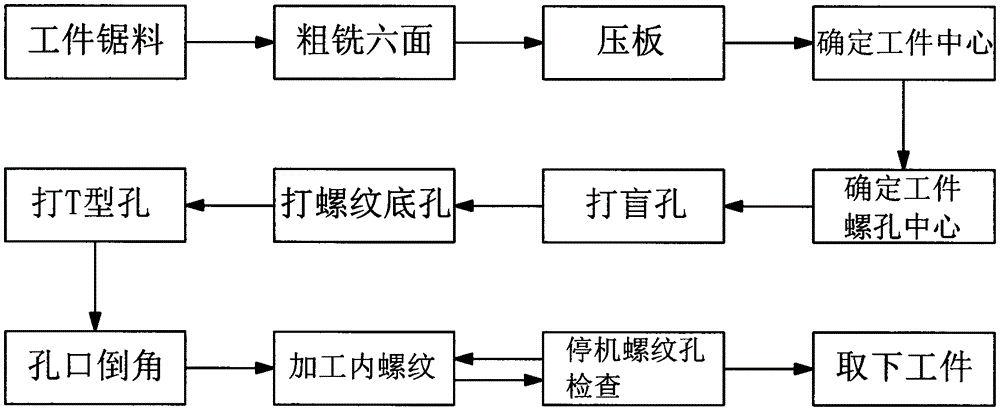

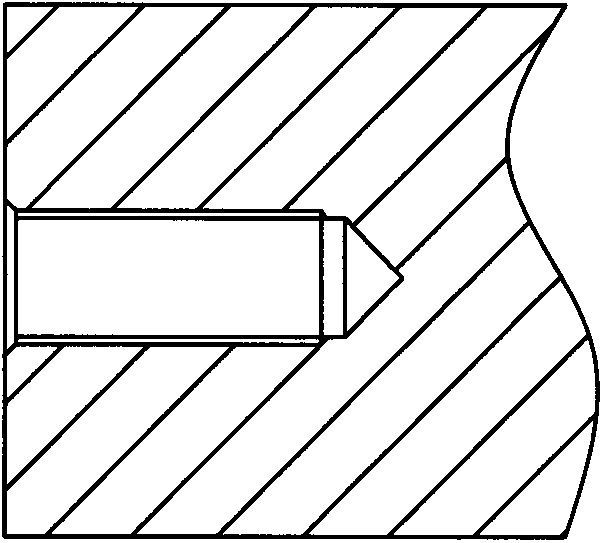

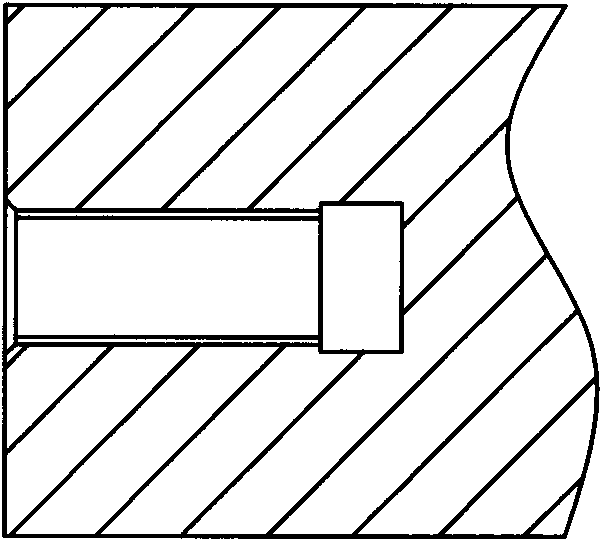

[0026] refer to figure 1 , figure 2 and image 3 Shown, the present invention a kind of processing method of ring screw hole on the mould, the technological process of this method is successively, workpiece sawing, rough milling six sides, pressing plate, determine workpiece center, determine workpiece screw hole center, punch blind hole, punch Threaded bottom hole, T-shaped hole punching, hole chamfering, internal thread processing, stop threaded hole inspection, and removal of the workpiece; The sawing machine intercepts the rectangular material steel plate used to make the mold from the large steel plate of the raw material; the drawing is an exploded view of the engineering details of the mold product;

[0027] The rough milling of the six sides is based on the size of the drawing and the machining allowance of the subsequent process is reserved, and the oxide layer on the six surfaces of the material steel plate is milled off with a milling machine to obtain a smooth p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com