Monofilament rewinding traction drawing mechanism

A monofilament and traction pulley technology, applied in the field of monofilament rewinding traction and drawing mechanism, can solve the problems of damage to the finished monofilament and the traction drawing die, affecting the rewinding effect, hidden quality problems, etc., so as to reduce the number of passes. Pulling force, ensure the quality of single wire drawing, improve the effect of service life

Inactive Publication Date: 2015-01-21

江苏金泰隆机电设备制造厂

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The traditional monofilament tends to generate frictional high temperature during the pay-off and drawing process, resulting in damage to the finished monofilament and the drawing and drawing die, affecting the ideal rewinding effect, and burying quality risks for subsequent production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the drawings and embodiments.

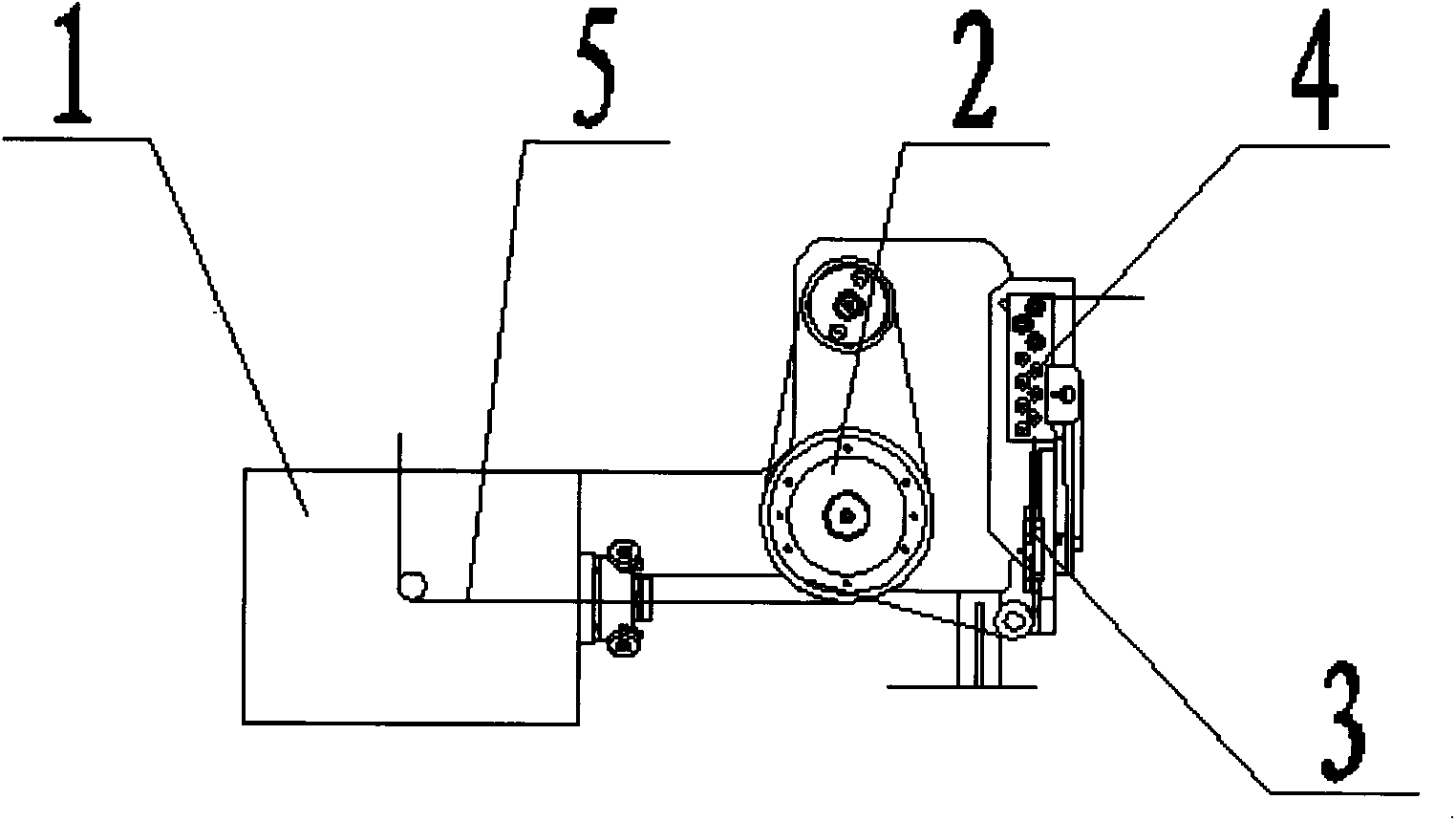

[0010] figure 1 As shown, a single-filament rewinding traction drawing mechanism includes a lubrication pool 1, a traction wheel 2, a finished product mold 3, and a wire dividing wheel 4. The lubricating pool 1, a traction wheel 2, a finished product mold 3 and a wire dividing wheel 4 pass through the single Wire 5 connection.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a monofilament rewinding traction drawing mechanism, including a drawing mechanism. A wire inlet port of the drawing mechanism is connected with a lube pool, through which the monofilament passes. The mechanism has simple structure and can effectively control the monofilament temperature rise in traction drawing, and ensure the quality of monofilament traction drawing and the service life of the traction drawing mold.

Description

Technical field [0001] The invention relates to a traction and drawing equipment, in particular to a single-filament rewinding traction and drawing mechanism, which is mainly used for the traction and drawing of wires such as steel wires for cords, copper wires and steel wires for rubber hoses. Background technique [0002] The finished monofilament rewinding is an important part of the steel cord production chain. Traditional monofilament is prone to high friction and high temperature during the drawing process of the pay-off direction, resulting in damage to the finished monofilament and traction drawing die, affecting the ideal rewinding effect, and laying down quality risks for subsequent production. Summary of the invention [0003] In view of the above-mentioned problems in the prior art, the present invention relates to a monofilament rewinding and drawing mechanism with a simple structure, which can effectively control the temperature rise of the traction and drawing monof...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B21C1/02B21C9/00

CPCB21C1/02B21C9/00

Inventor 吴文军

Owner 江苏金泰隆机电设备制造厂

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com