High-efficiency multidirectional vibration energy collection device

A vibration energy harvesting, multi-directional technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problem of narrow working frequency band, low energy efficiency, vibration excitation, etc. problems, to achieve strong nonlinearity, good reliability, and the effect of protecting piezoelectric materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

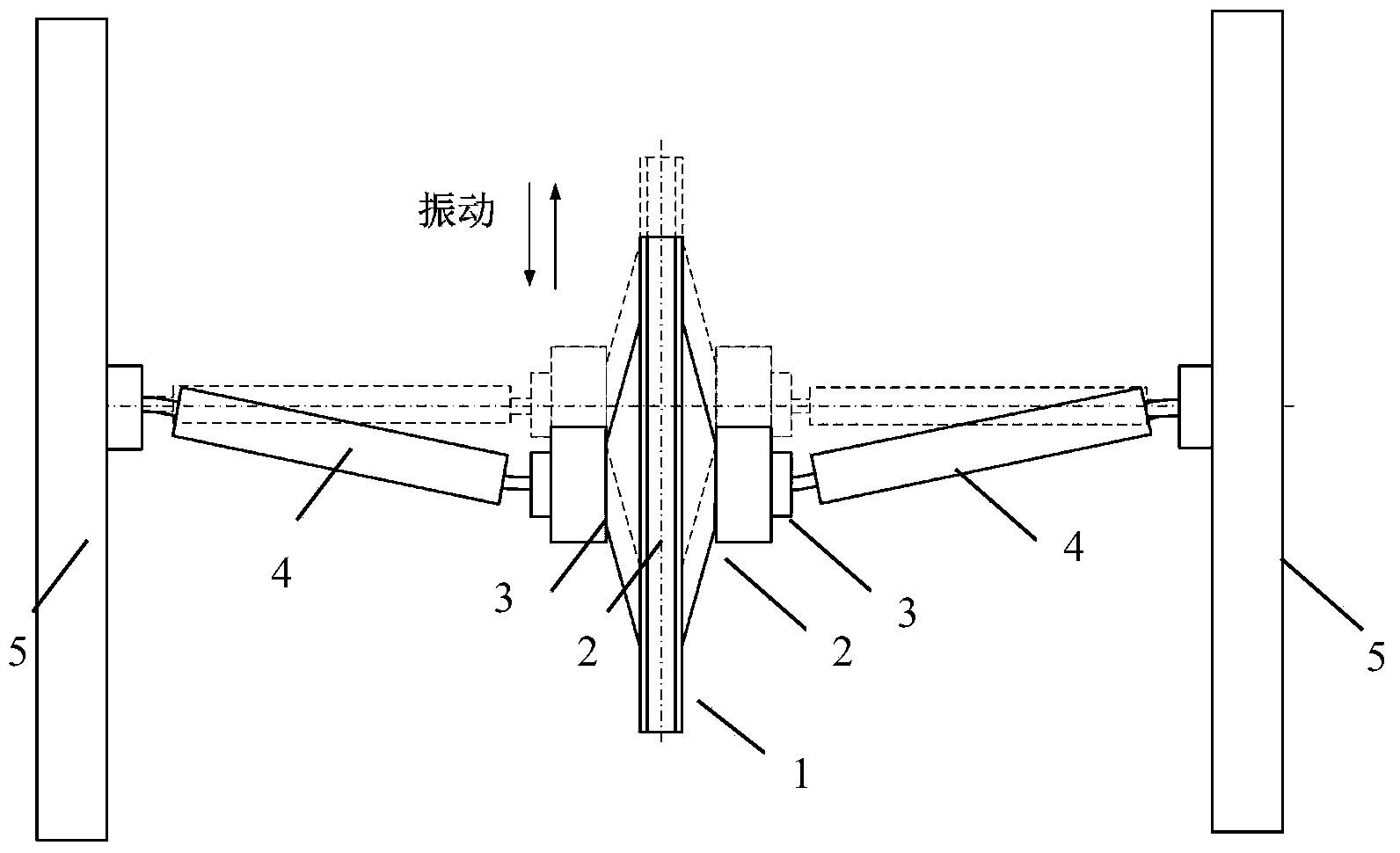

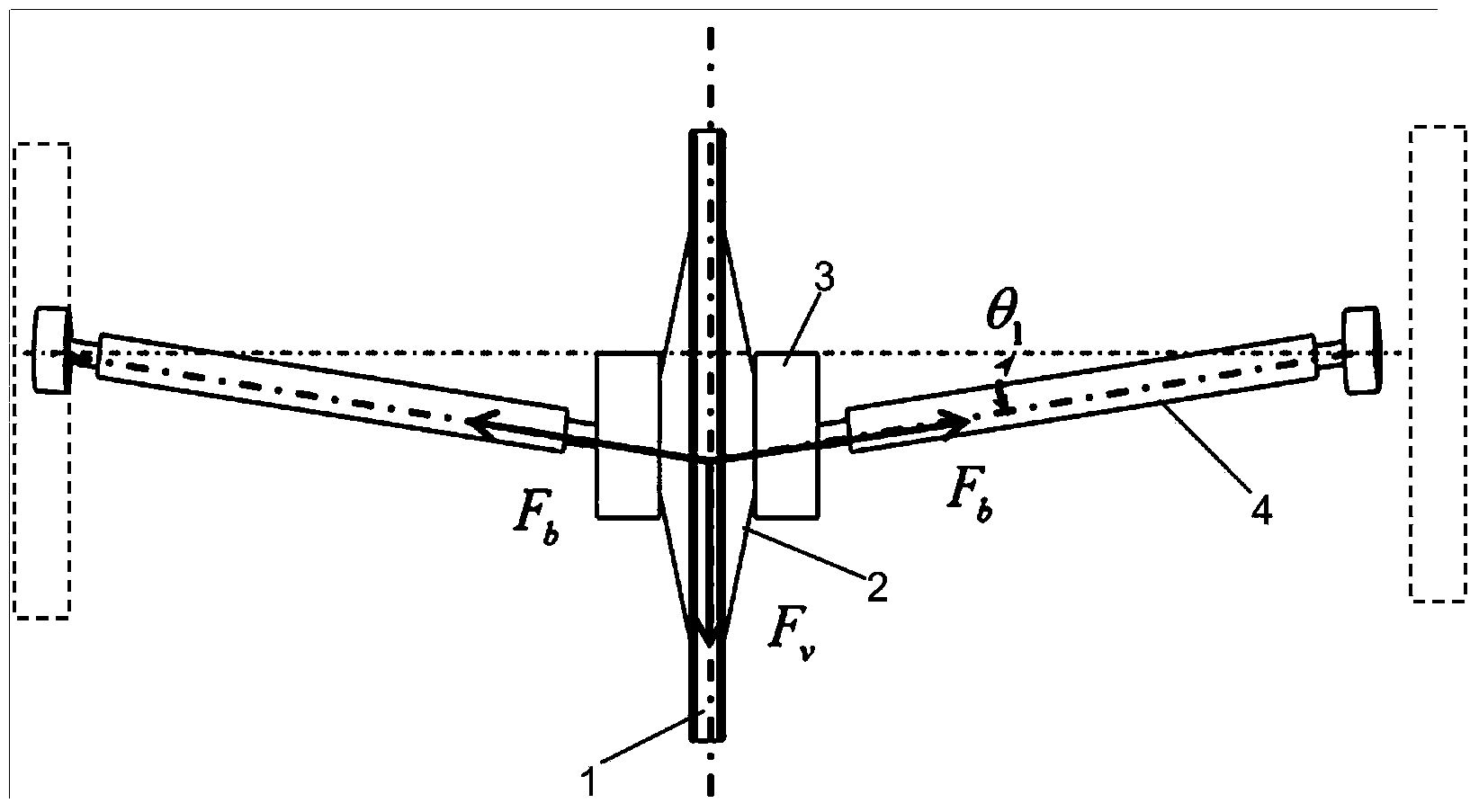

[0058] A prototype was built to verify the invention. PZT-5A (40×15×0.5mm 3 ) was used as the piezoelectric material for the prototype. The total mass of the masses is 100g. The elastic beam is aluminum and its size is 50×4×0.38mm 3 . One end of the elastic beam is fixed on the base, and the other end is fixed on the central bending extension element. The central curved tensile element consists of a PZT-5A plate and two arcuate aluminum plates (thickness 0.5mm). The bow-shaped aluminum plate is fixed on the PZT plate by epoxy resin. The prototype machine was installed on a vibration test bench, and a 300KΩ resistor was connected externally. The excitation vibration is 10-30 Hz with an acceleration of 0.5 g. The output voltage was recorded by a digital oscilloscope. Energy output is the square of the output voltage divided by the resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com