Water-cooling conductor rotor, permanent magnet eddy-current speed controller and permanent magnet eddy-current coupler

A conductor rotor, permanent magnet eddy current technology, applied in the direction of permanent magnet clutch/brake, electric brake/clutch, asynchronous inductive clutch/brake, etc., can solve the problem of water cooling in the central area, avoid insufficient central cooling, and improve the Cooling, cooling effect guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

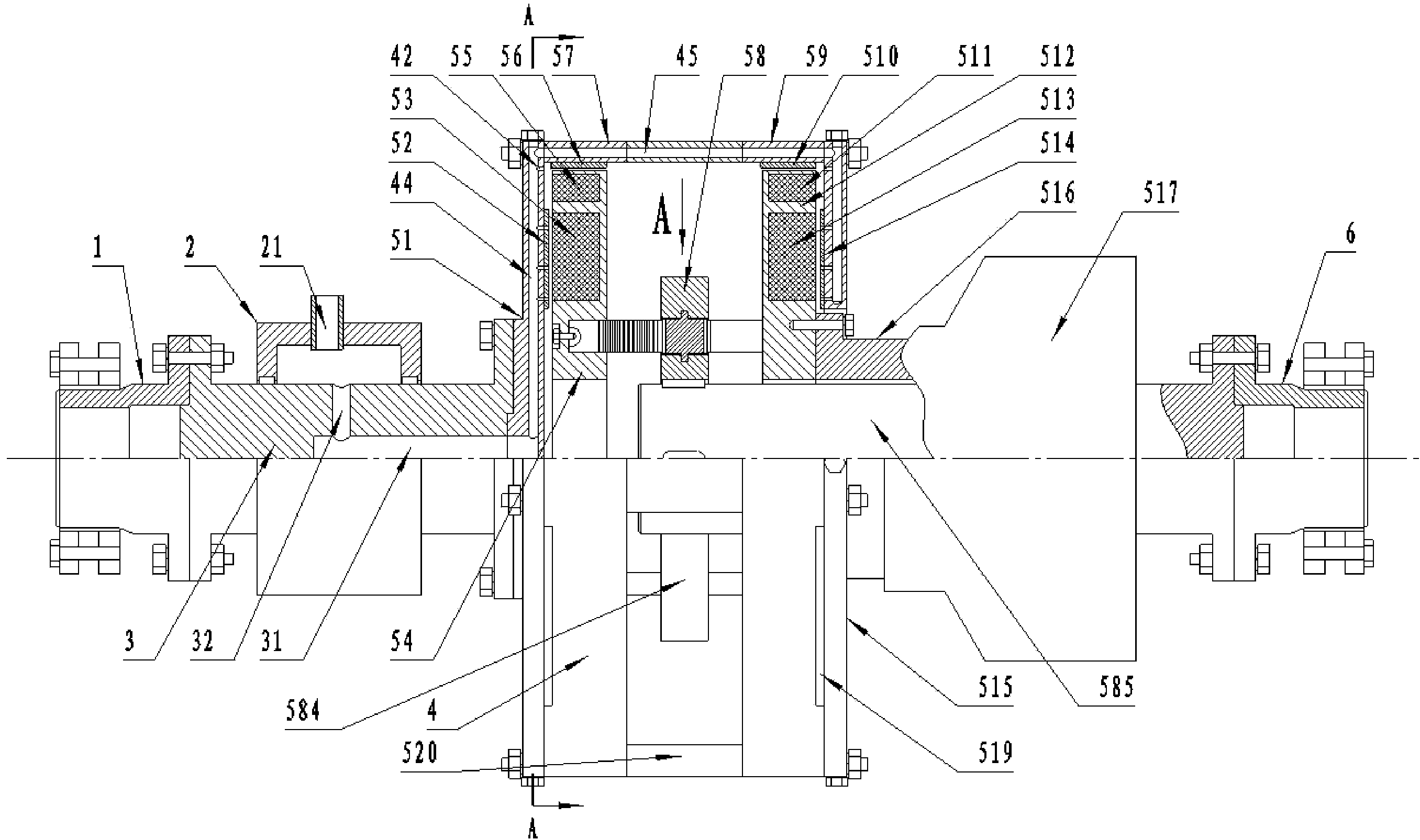

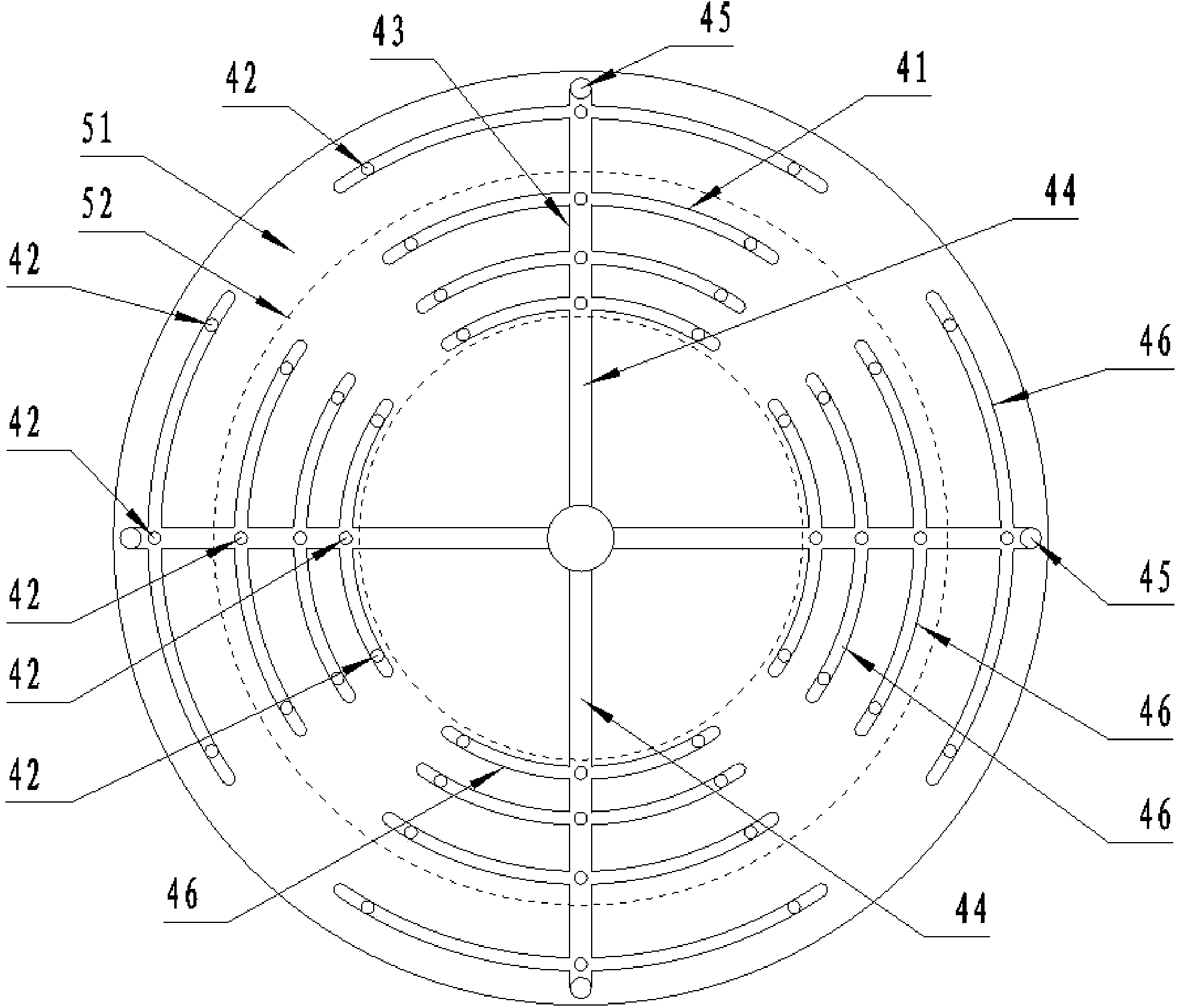

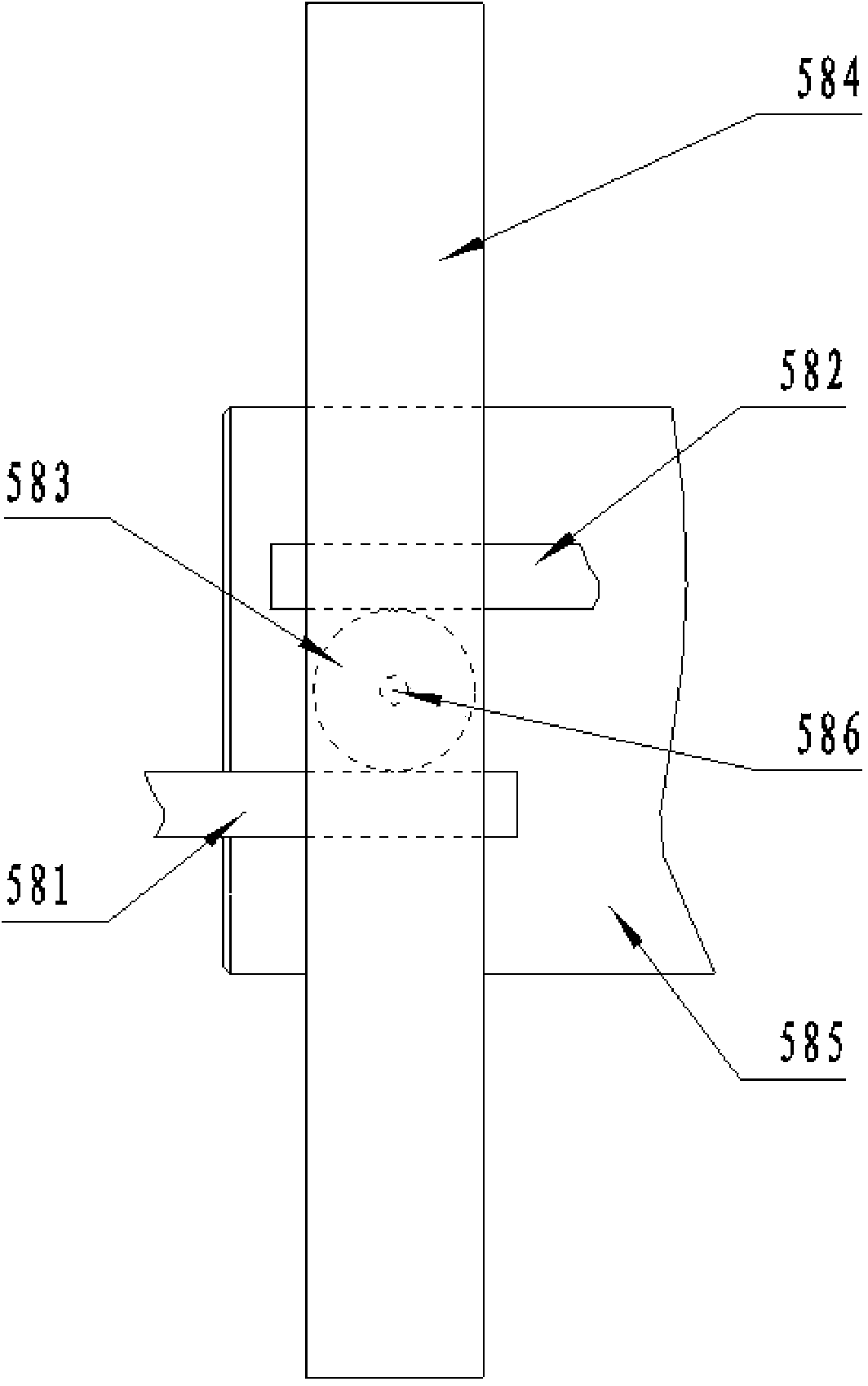

[0028] The water-cooled permanent magnet eddy current governor according to the present invention will be further described in detail below in conjunction with the accompanying drawings. A water-cooled conductor rotor, the water-cooled conductor rotor includes a housing 4 and a hollow shaft 3, the housing 4 and the hollow shaft 3 are coaxially arranged (that is, the axis of the housing 4 coincides with the axis of the hollow shaft 3) and the housing 4 It is fixedly connected with one end of the hollow shaft 3, the main cooling water line 31 is arranged in the hollow shaft 3, the water inlet 32 is arranged on the hollow shaft 3, the cooling water branch line 41 is arranged in the side wall of the casing 4, and the cooling water branch line 41 is arranged in the casing 4 Along the radial direction of the conductor rotor, a plurality of water jets 42 for spraying water into the conductor rotor are sequentially provided, and the water inlet 32 communicates with the water jets 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com