Engine electric control system component function testing system and method

An electronic control system and functional testing technology, which is applied in the general control system, electrical test/monitoring, control/regulation system, etc., can solve the problems of not being suitable for batch testing of electronic control unit components, high cost of bench testing, and poor flexibility , to achieve the effect of simple structure, low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0035] The present invention proposes a method for statically simulating engine dynamics to detect the input / output of engine electronic control unit components based on the working characteristics of each electronic control unit, and designs a specific engine electronic control system component function test system.

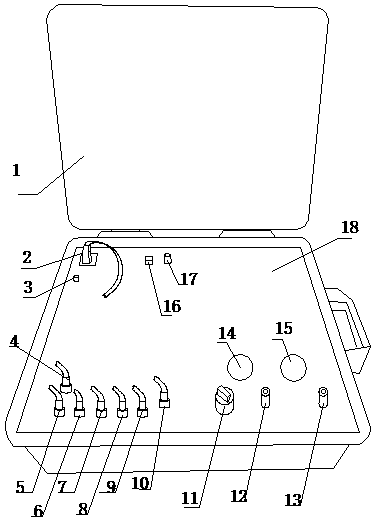

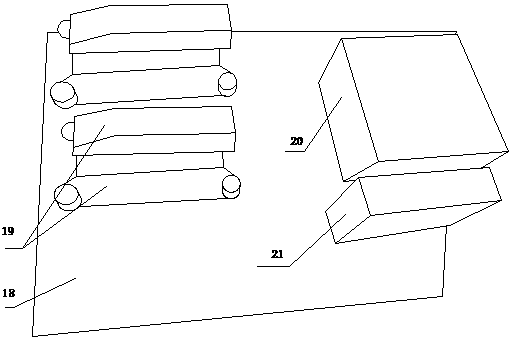

[0036] Such as figure 1 , 2 As shown, the system includes a trolley case 1. A detection panel 18 is fixed inside the trolley case 1. A compressed air pump 20, an electronic control unit ECU19 and a power cord socket 2 connected to the electronic control unit ECU19 are arranged on the detection panel 18. , 220V power switch 3, 24V power switch 16, potential knob 17, EPR system port 5, low-voltage solenoid valve port 6, exhaust gas control valve port 7, electronic throttle port 8, oxygen concentration sensor port 9, DEPR system port 54 and OBD A system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com