Light reflecting sticking film

A technology of reflective stickers and reflective layers, applied in optics, optical components, lamination devices, etc., can solve the problems of lack of diversity, single type, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, and are described in detail as follows:

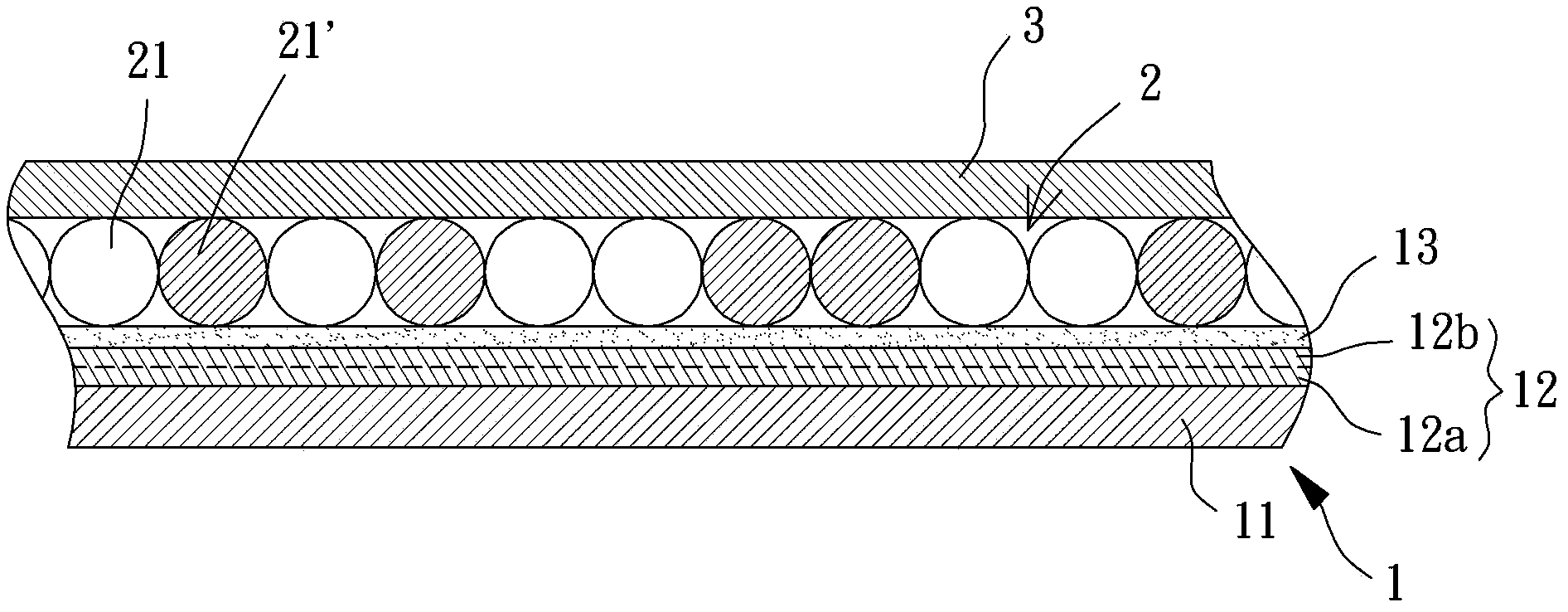

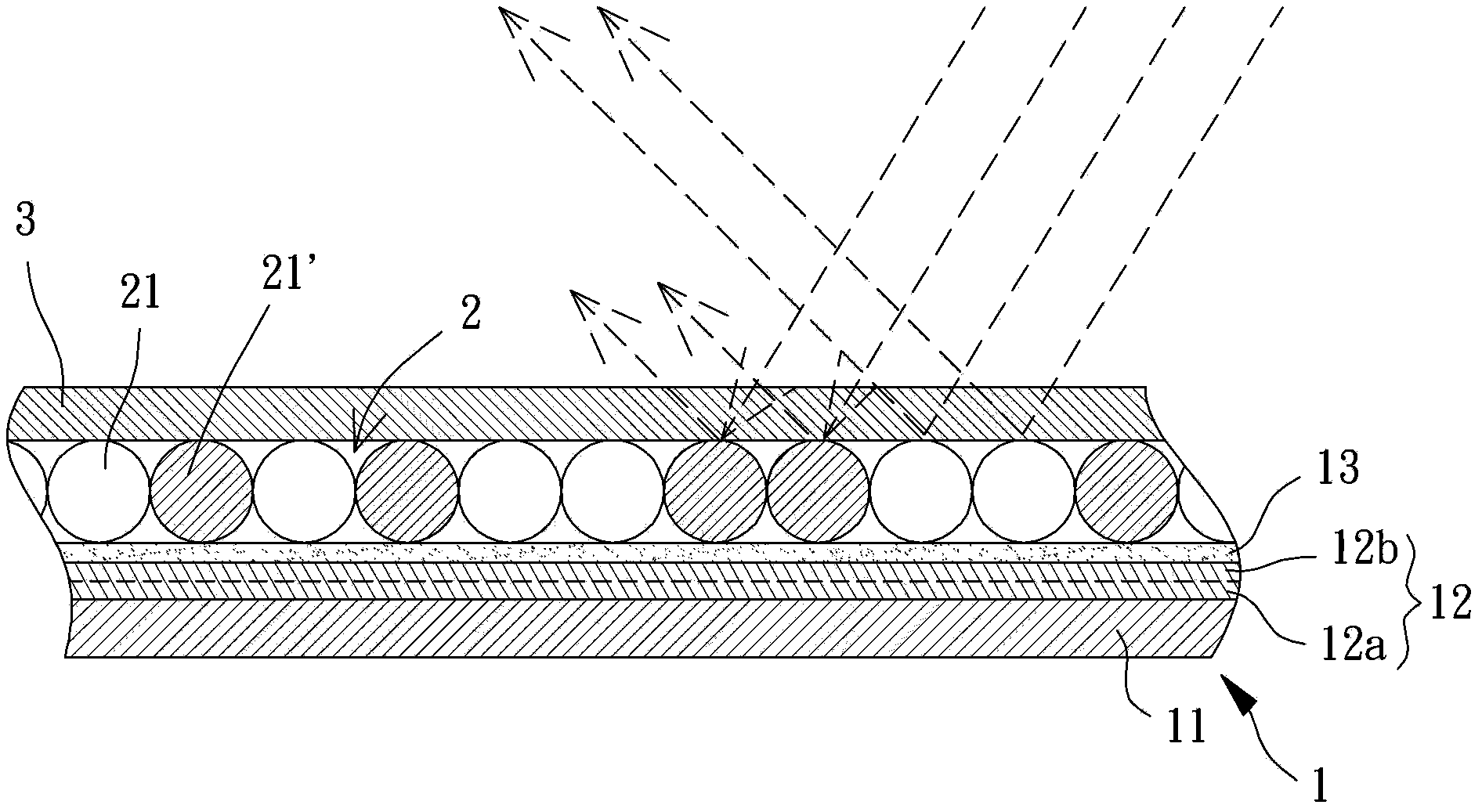

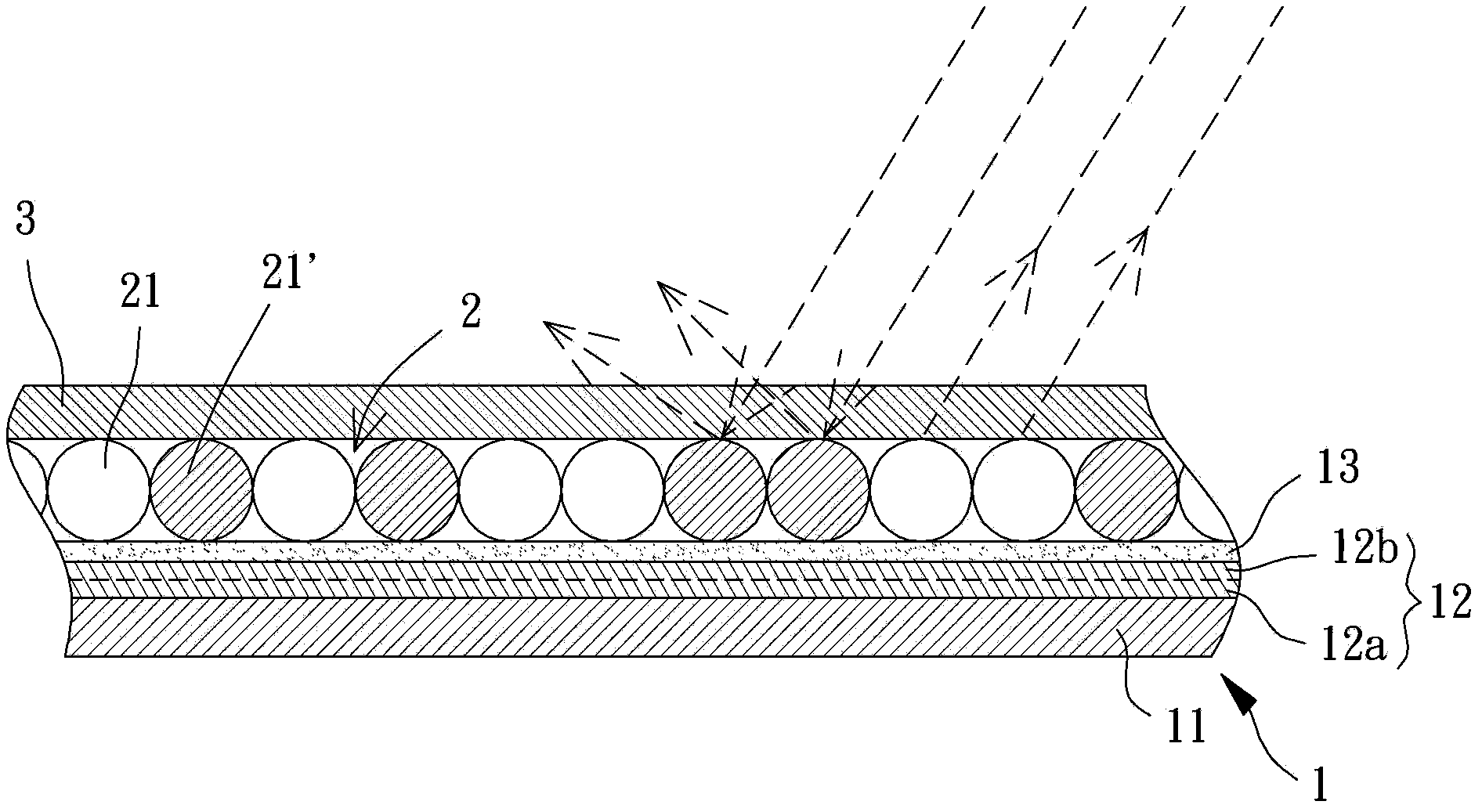

[0032] Please refer to figure 1 As shown, it is a preferred embodiment of the present invention, the reflective film includes a base layer 1, a reflective layer 2 and a color layer 3, the reflective layer 2 and the color layer 3 are coated on the base layer 1 Above (As far as the direction of the drawing is concerned, this article is based on the direction of the drawing).

[0033] The base layer 1 includes a substrate 11 , an adhesive layer 12 and digital bright particles 13 , and the adhesive layer 12 and digital bright particles 13 are sequentially arranged on the substrate 11 . Wherein, the substrate 11 can be water transfer paper, thermal transfer paper or self-adhesive release p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com