Double-suction impeller

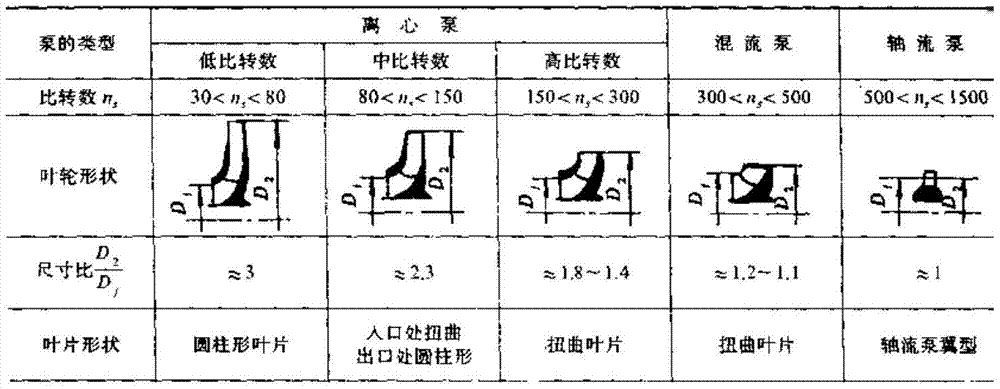

A double-suction impeller and blade technology, applied in the field of machinery, can solve the problems of large impact loss at the impeller outlet, low cavitation resistance and efficiency of the impeller, and narrow application range of double-suction pumps, so as to eliminate secondary backflow and broaden the application range , The effect of expanding the specific speed range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

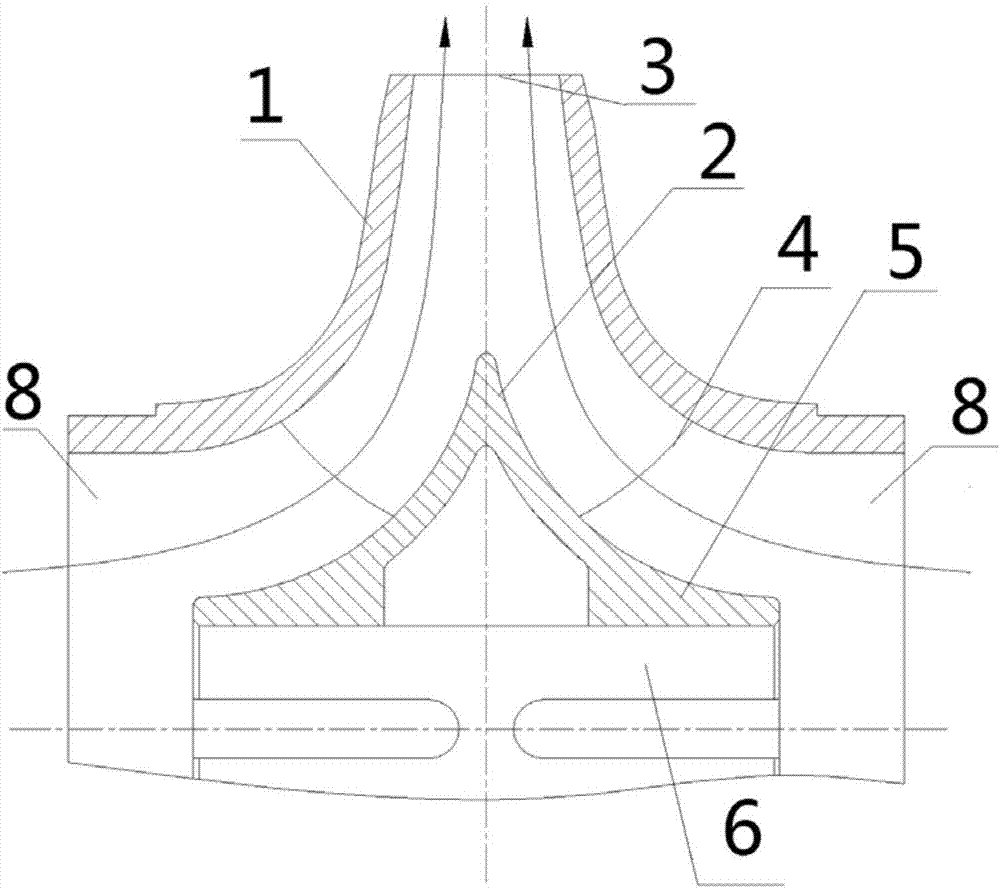

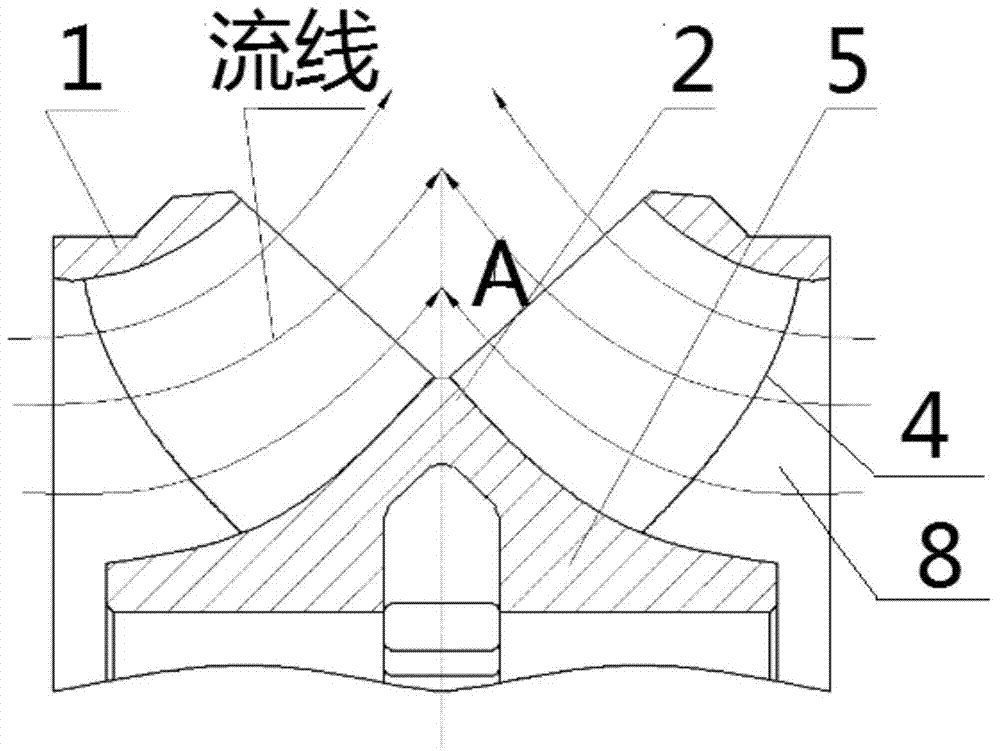

[0025] The invention provides a double-suction impeller, which includes a front cover 1, a rear cover 2, blades 4, a hub 5 and a shaft hole 6, the outlet side of the water outlet 3 is V-shaped, and the apex of the V is at the rear cover. 2 is provided with an upwardly protruding baffle 7, the two sides of the baffle 7 are inwardly concave arc, and the shape of the baffle 7 transitions smoothly as the flow channel changes. The invention increases the specific rotational speed of the impeller, minimizes hydraulic loss, has a symmetrical structure, has no axial force, and runs smoothly.

[0026] The working principle of the double-suction impeller of the present invention is: the integrated body of the hub 5, the rear cover 2 and the partition 7 and the front cover 1 form a double flow channel 8, the liquid flow enters the flow channel 8, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com