Hand-held cap screwing machine

A capping machine, hand-held technology, applied in threaded bottle caps, bottle/container caps, capping containers with caps, etc., can solve the problem of single-targeted operation of the capping machine, and achieve simple structure and reasonable design , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] A hand-held capping machine of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

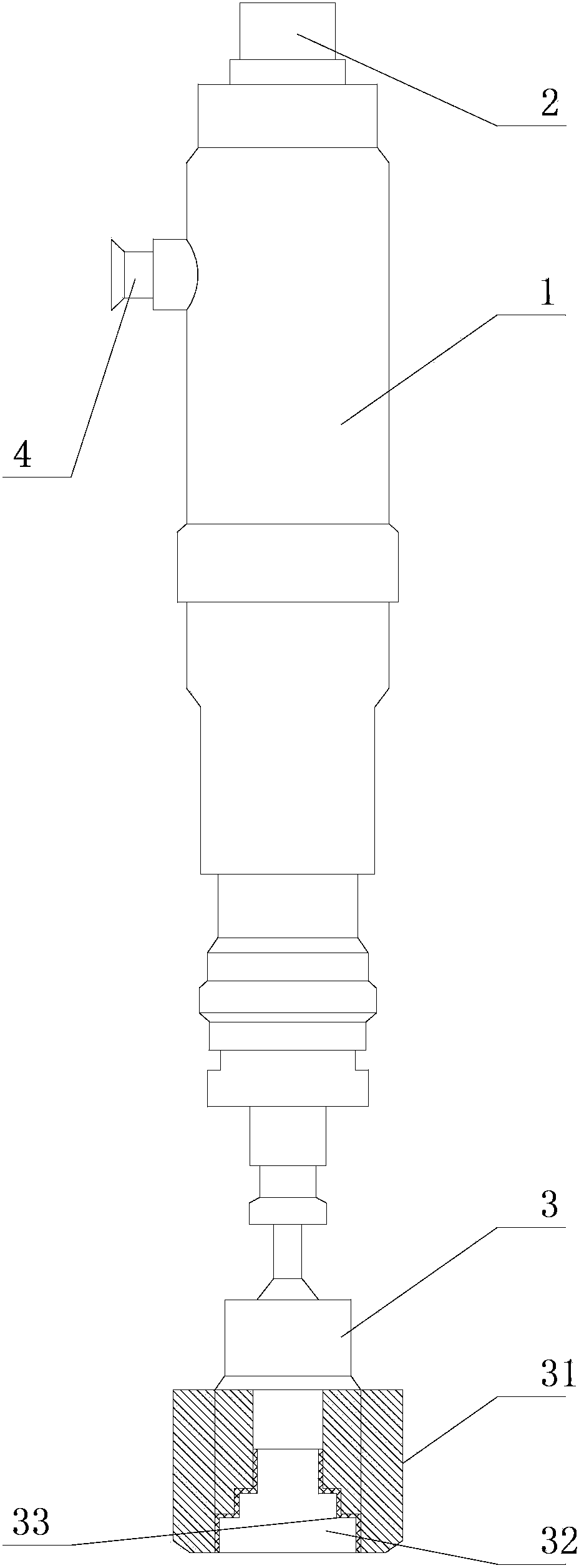

[0012] as attached figure 1 As shown, a hand-held capping machine includes a fuselage 1, the top of the fuselage 1 is provided with a motor 2, and the power output shaft of the motor 2 is linked to the capping head 3 at the lower end of the fuselage 1 through a transmission shaft. The motor 2 is electrically connected to the switch 4 arranged on one side of the fuselage 1. The capping head 3 includes a cylindrical shell 31, and the shell 31 is provided with slots 32 with inner diameters from large to small from the outside to the inside.

[0013] In this embodiment, an anti-slip cushion layer 33 is provided on the side wall of the card slot 32 .

[0014] As shown in the drawings, the hand-held capping machine of this embodiment is provided with three kinds of slots 32 with different inner diameters, which can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com