Thread seal tape winding equipment

A raw material belt and equipment technology, applied in the field of automation control, can solve the problems of high labor intensity and assembly cost, low assembly efficiency, and increased probability of water leakage, so as to reduce labor cost and labor intensity, realize production efficiency, and ensure finished products quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

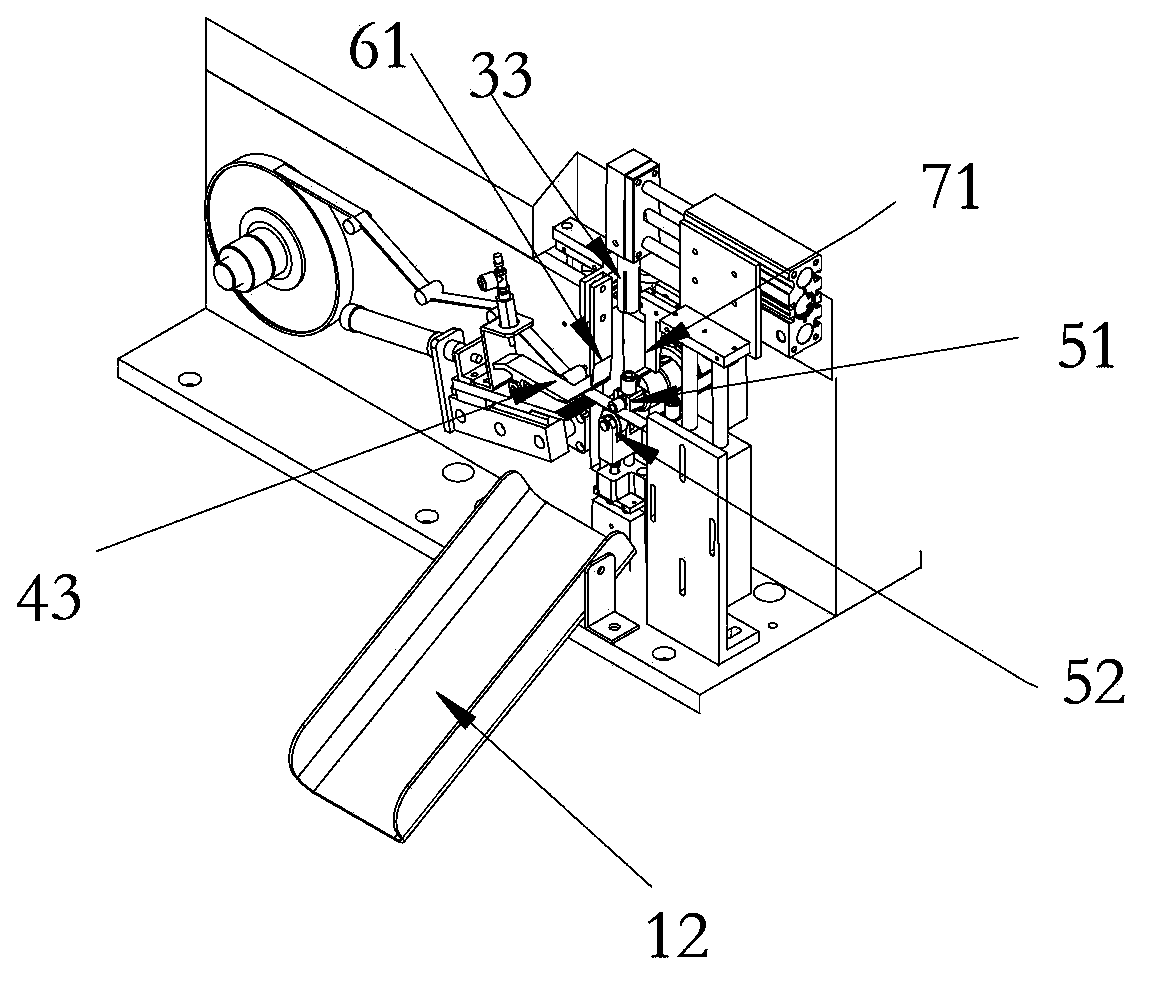

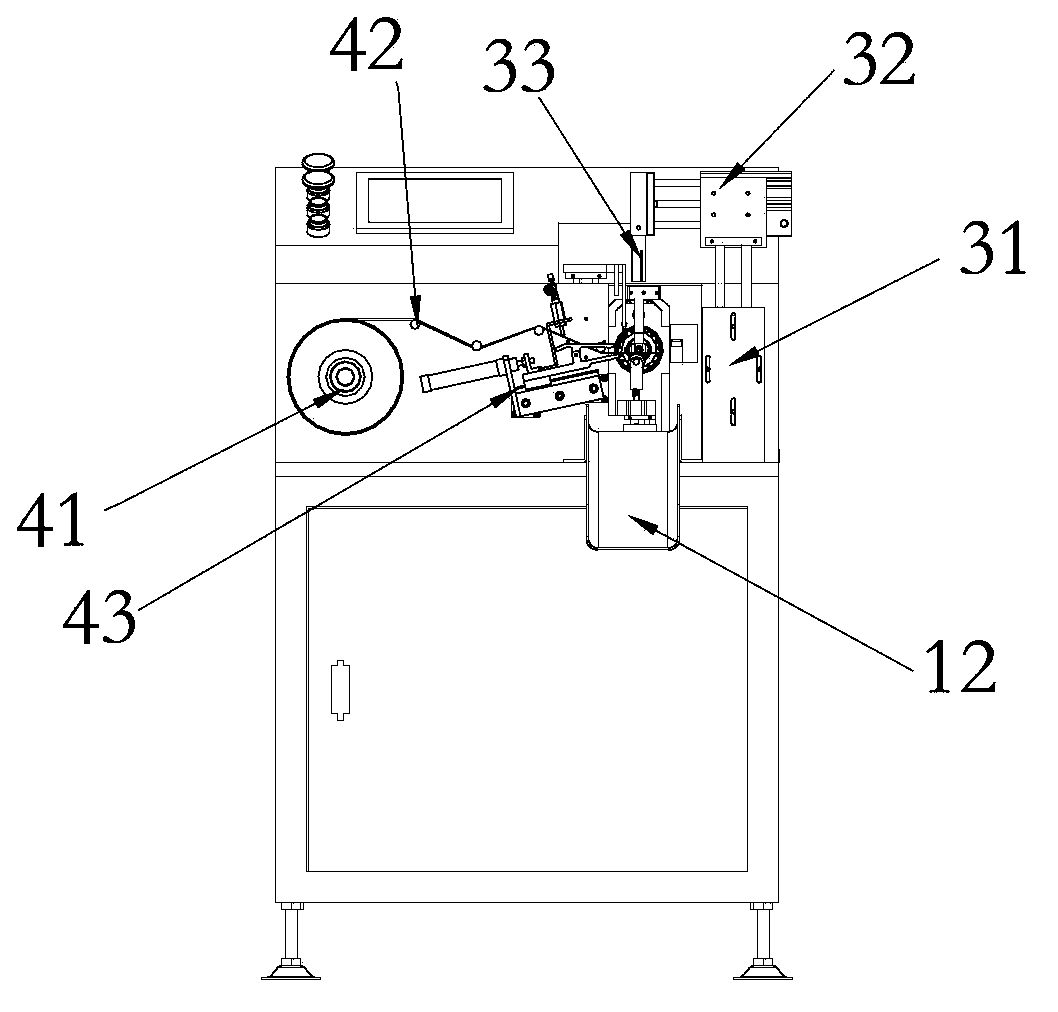

[0047] An embodiment of the raw tape winding device of the present invention, such as Figure 1 to Figure 5 shown.

[0048] The raw material tape winding equipment provided by the embodiment of the present invention is used to wind the raw material tape onto an L-shaped external threaded joint, including a bracket 1, a feeding device, a retrieving device, a conveying device, a winding device, a cutting device and a pushing device;

[0049] The feeding device, the retrieving device, the conveying device, the winding device, the cutting device and the pushing device are all arranged on the support 1;

[0050] The taking device takes out the L-shaped external thread joint from the feeding device, and transfers the L-shaped external thread joint to the winding device;

[0051] The conveying device conveys the raw material tape to the winding device;

[0052] The winding device winds the raw material tape on the L-shaped external thread joint;

[0053] The cutting device is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com