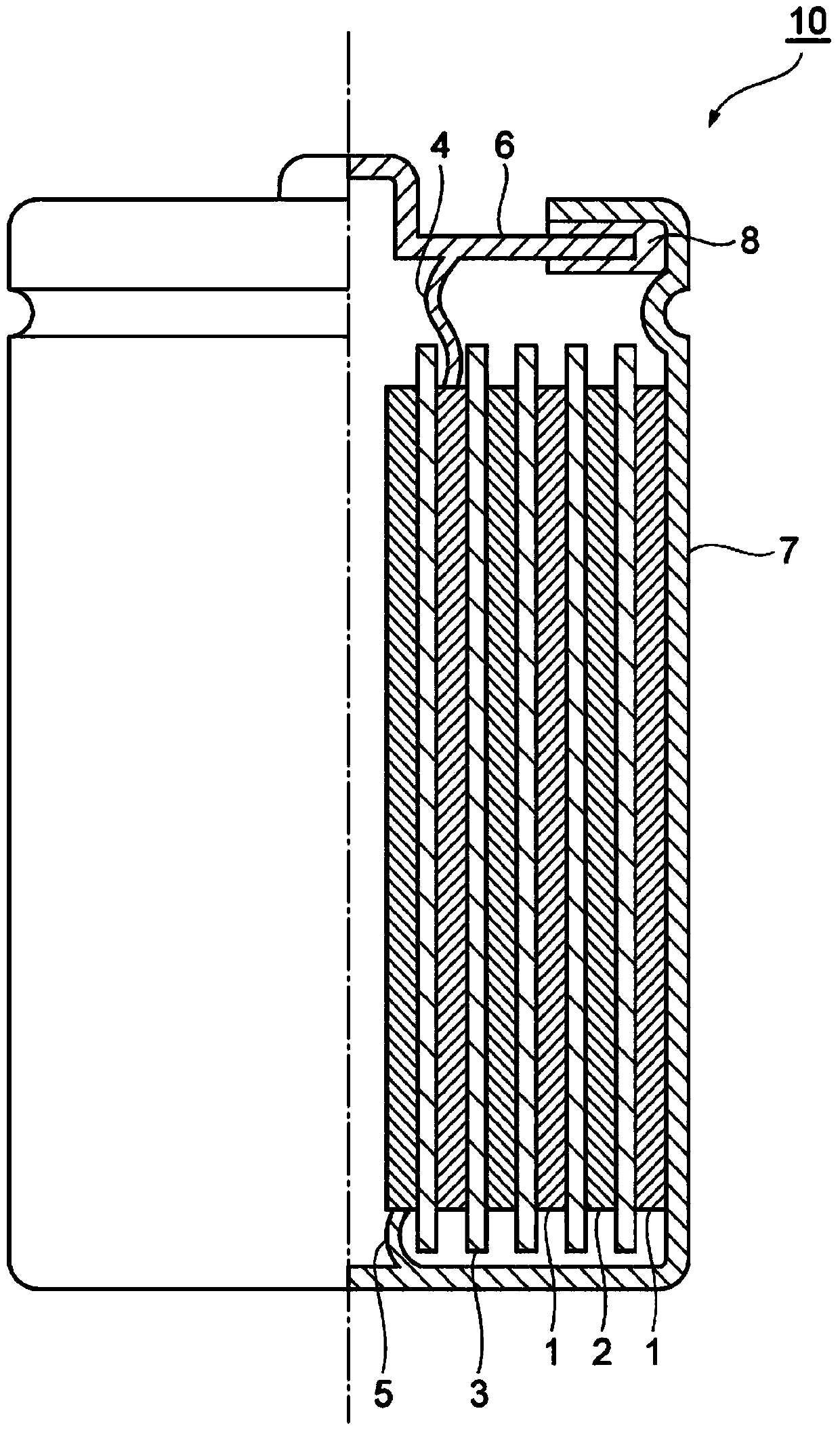

Separator for electrochemical element and fabrication method for same

A technology of electrochemical components and diaphragms, which is applied in the field of diaphragms for electrochemical components and its manufacturing, which can solve the problems of diaphragm shrinkage, increase in the contact area between positive and negative electrodes, etc., and achieve improved safety, excellent flexibility, and high heat resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

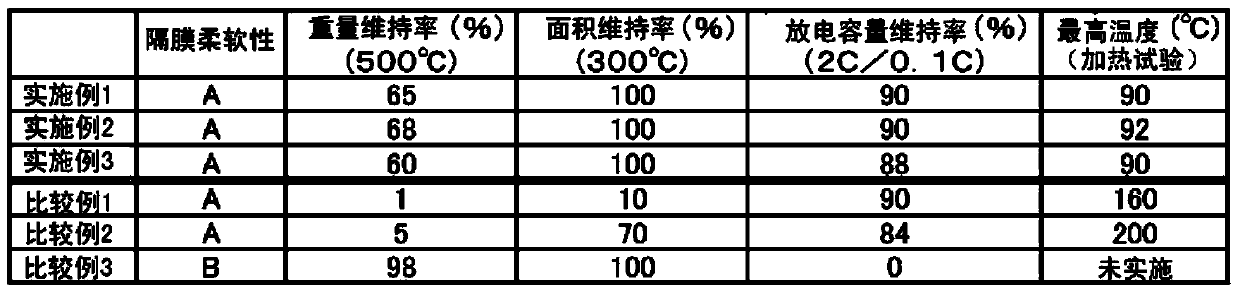

Embodiment 1

[0089]

[0090] 0.5 g of glass fibers (CMLF208, manufactured by Nippon Plate Glass, with an average fiber diameter of 0.8 μm) and 600 ml of ion-exchanged water were added to a mixer, and stirred for 2 minutes. Next, 2.24 g of pulp fibers obtained by beating kraft paper were added to a mixer, and stirred for 3 minutes to prepare a slurry. This slurry was poured into a standard sheet machine papermaking device (Model No. 2545, manufactured by Kumagai Riki Kogyo Co., Ltd.), filled with a predetermined amount of ion-exchanged water, stirred well, and then drained to obtain a sheet. Next, the filter paper and cardboard (Japanese original text: ダミーpaper) are superimposed on the sheet, and after couching, the sheet and the filter paper are peeled off from the cardboard, and according to the contact with the sheet, Place it on the SUS plate in the same way and pressurize it at the specified pressure for 3 minutes. Thereafter, the filter paper was peeled off, and the sheet was dried...

Embodiment 2

[0108]0.5 g of glass fibers (CMLF208, manufactured by Nippon Plate Glass, with an average fiber diameter of 0.8 μm) and 600 ml of ion-exchanged water were added to a mixer, and stirred for 2 minutes. Next, 5 mL of cationic polymer coagulant polydiallyldimethylammonium chloride (manufactured by Aldrich), 2.5 g of alumina sol (Alminasol 250, manufactured by Nissan Chemical), and anionic polymer coagulant Hi 10 mL of Holder 351 (manufactured by Kurita Industries) and 2.24 g of pulp fibers obtained by beating kraft paper were stirred for 3 minutes to prepare a slurry. The slurry was poured into a standard sheet machine papermaking device and filled with a specified amount of ion-exchanged water, stirred thoroughly, and then drained. Next, after overlapping the filter paper and the cardboard and placing it on the couch roll, peel off the sheet from the cardboard together with the filter paper, place it on the SUS board in such a way that it is in contact with the sheet, and press i...

Embodiment 3

[0110] 0.25 g of glass fibers (CMLF208, manufactured by Nippon Plate Glass, with an average fiber diameter of 0.8 μm) and 600 ml of ion-exchanged water were added to a mixer, and stirred for 2 minutes. Next, 2.24 g of pulp fibers obtained by beating kraft paper were added to a mixer, and stirred for 3 minutes to prepare a slurry. This slurry was poured into a standard sheet machine papermaking device (Model No. 2545, manufactured by Kumagai Riki Kogyo Co., Ltd.), filled with a predetermined amount of ion-exchanged water, stirred well, and then drained to obtain a sheet. Next, after overlapping the filter paper and cardboard on the sheet and standing it on the couch roll, the sheet and the filter paper are peeled off from the cardboard, placed on the SUS board in such a way that it is in contact with the sheet, and pressed at a specified pressure. Pressurize for 3 minutes. Thereafter, the filter paper was peeled off, and the sheet was dried at 105° C. for 2 hours, then heat-tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com