fuel high pressure pump

A high-pressure pump and fuel technology, applied in fuel injection devices, charging systems, engine components, etc., can solve problems such as restrictions, large bearing flow, etc., and achieve the effect of saving time and materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

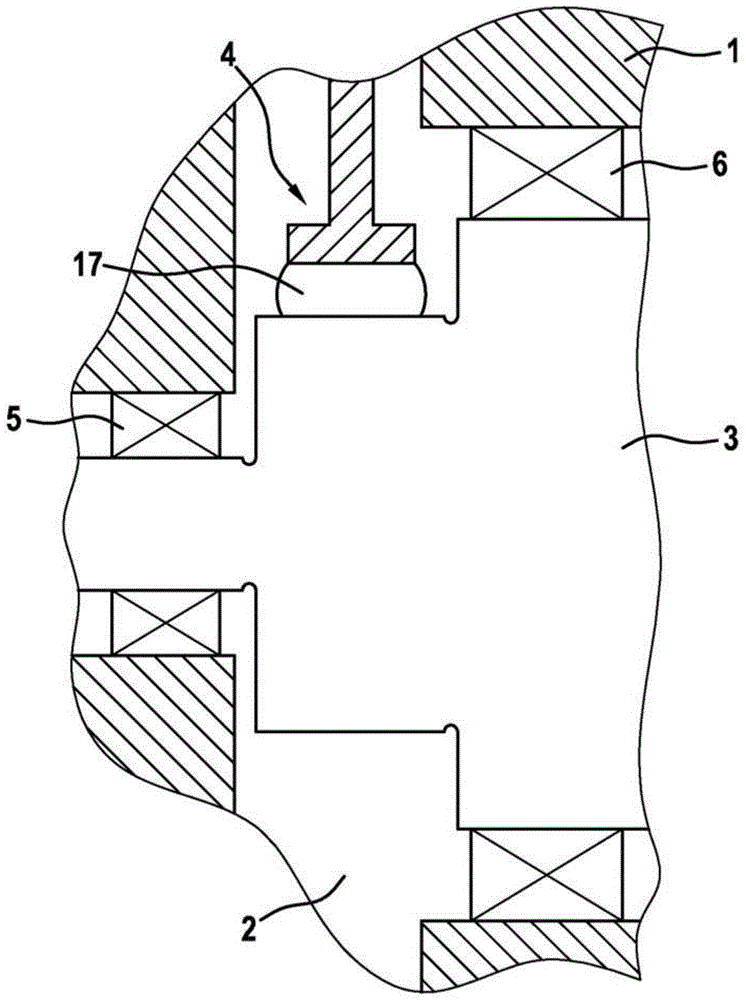

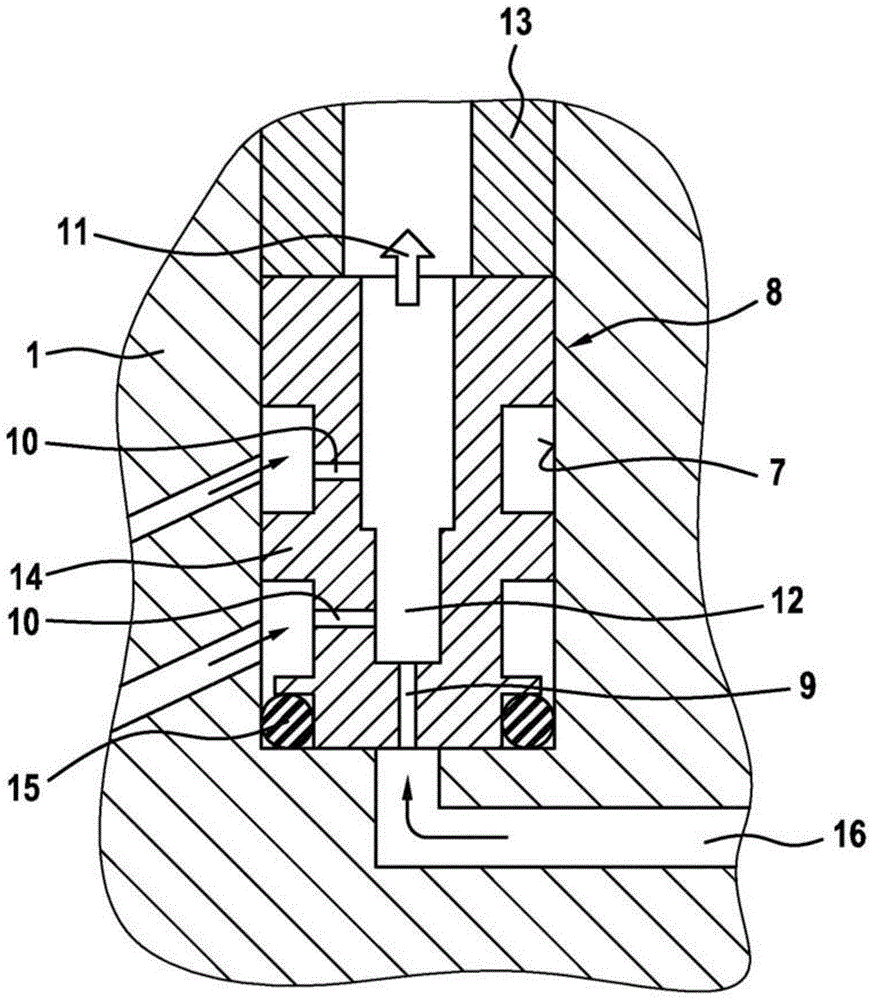

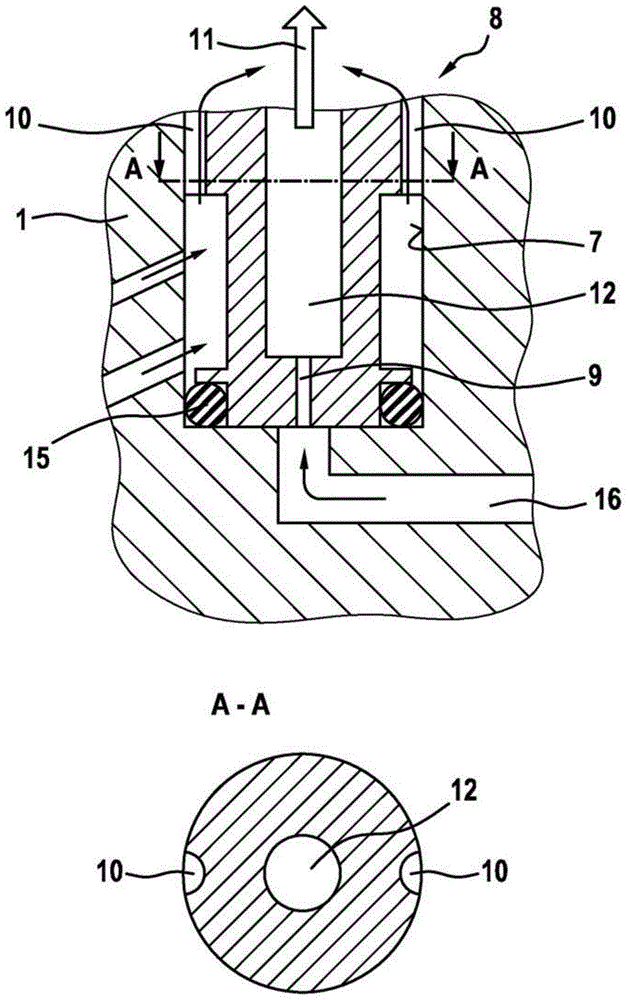

[0021] figure 1 A schematic sectional view of the pump housing 1 shown in detail of a high-pressure fuel pump is shown. A high-pressure fuel pump supplies fuel from a low-pressure system into a high-pressure accumulator, from which fuel is withdrawn by a fuel injector for injection into a combustion chamber of an internal combustion engine. The internal combustion engine is preferably a diesel powered self-ignition internal combustion engine.

[0022] The high-pressure fuel pump has a pump housing 1 in which a drive chamber 2 is formed. Fuel is delivered from the low-pressure system to the drive compartment 2 . A drive shaft 3 is supported in the pump housing 1 , protrudes into the drive chamber 2 and interacts with the pump piston 4 via a roller tappet 17 . The pump piston 4 conveys the fuel entering the pump working chamber into a high-pressure accumulator, the so-called common rail. The fuel entering the pump working chamber is dosed by a metering device (not shown here...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com