Method and apparatus for placing or excavating cavities in mountains

A cavity and equipment technology, applied in mining equipment, welding equipment, metal processing equipment, etc., can solve problems such as equipment failure to be implemented, and achieve the effect of avoiding overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

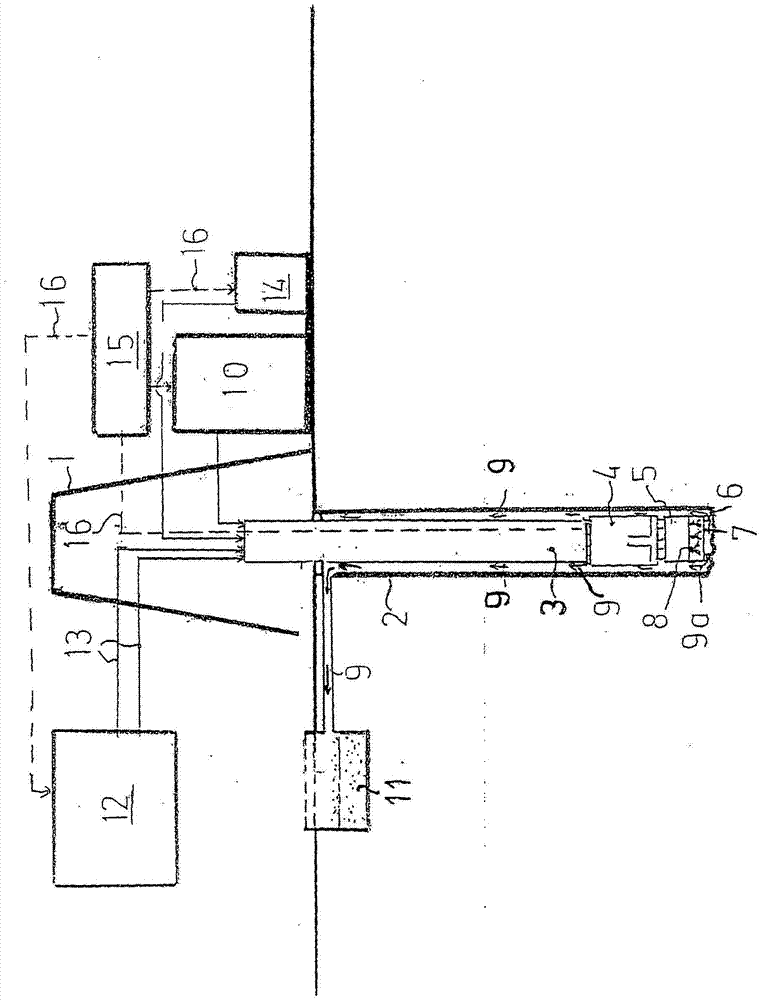

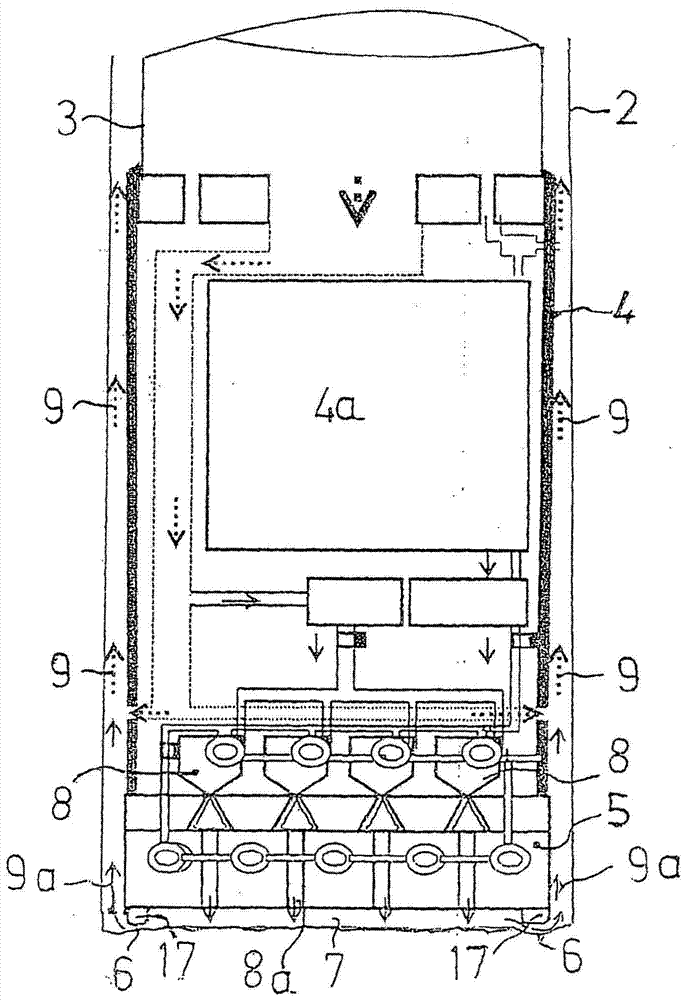

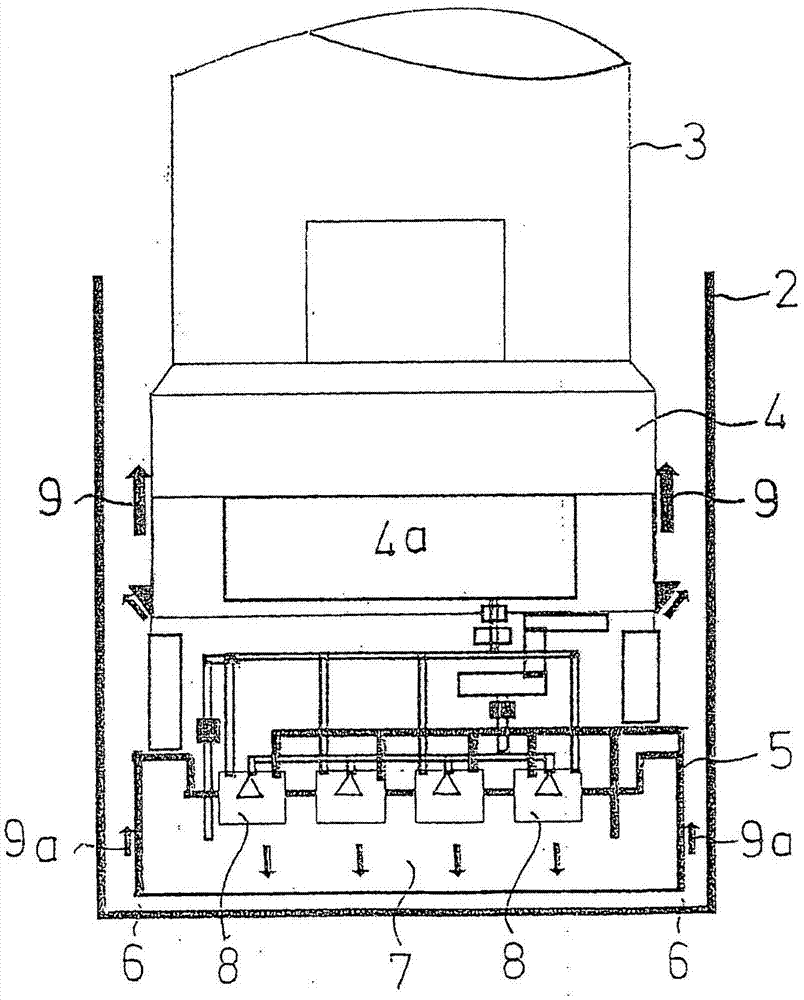

[0031] exist figure 1 In , the excavation platform erected on the surface is marked with reference numeral 1 . This drilling platform 1 is provided with the usual means for inserting a feed and supply device 3 for advancing and supplying a driving head 4 arranged in the cavity 2 to be produced. On its side facing the front of the cavity 2 , the drilling head 4 is provided with a thermal protection cover 5 which covers the front of the cavity 2 up to a gap 6 extending around the periphery and forms a dynamic pressure chamber 7 with the front of the cavity 2 .

[0032] A plurality of electric plasma generators 8 in the form of plasma burners are arranged in or on the heat shield 5 , and their heat melts or vaporizes the rocks located in front of the cavity 2 .

[0033] The rock melted and / or evaporated in front of the cavity 2 is removed from the cavity 2 by means of the gaseous conveying medium indicated by the arrow 9 . This gaseous conveying medium 9 is nitrogen, which is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com