Method for monitoring unit power generation coal consumption deviation caused by variation of gas boiler operating parameters

A technology for gas boilers and operating parameters, which is used in electrical digital data processing, special data processing applications, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The present invention will be further described below in conjunction with the accompanying drawings.

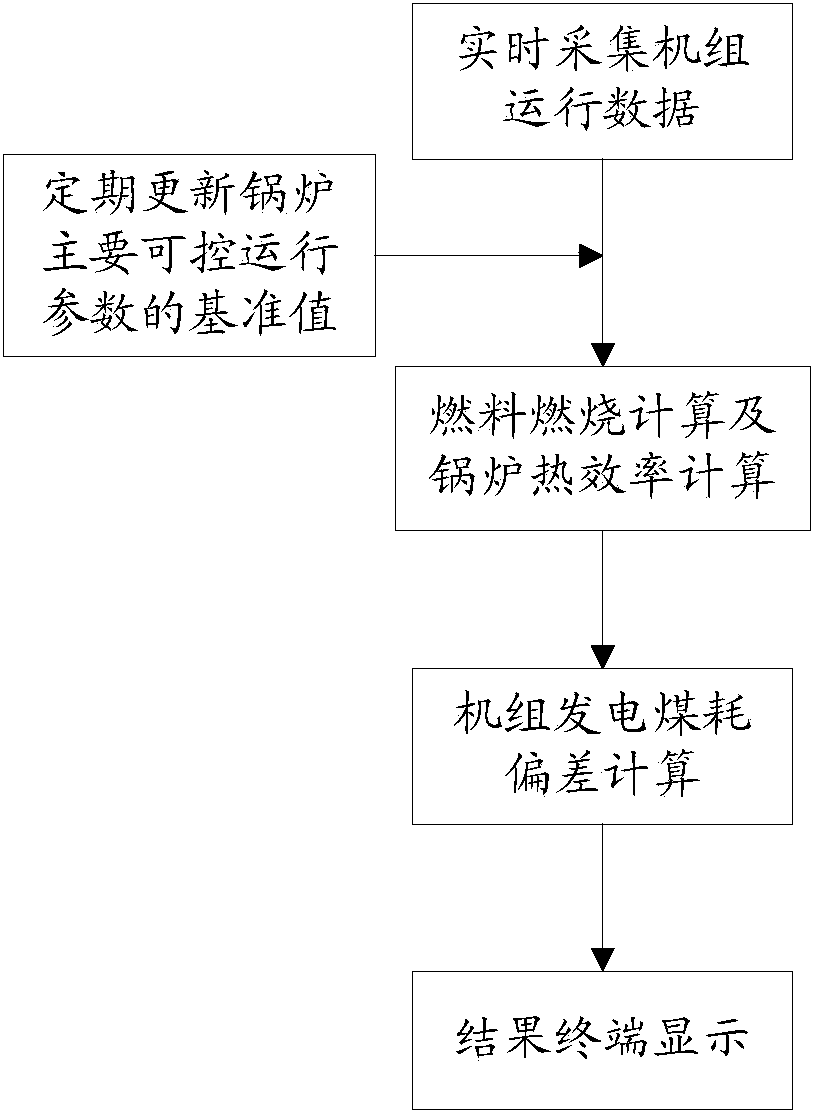

[0078] Such as figure 1 As shown, the method for monitoring the coal consumption deviation of the unit power generation caused by the change of the operating parameters of the gas boiler of the present invention, the specific steps are:

[0079] Obtain benchmark data for gas boiler operating parameters:

[0080] Regularly read the historical operation data of the past period of time from the historical database of the generator set, and use the data mining method to analyze the data to obtain the continuously updated benchmark value data of the main controllable operating parameters of the boiler, including the benchmark value of exhaust gas oxygen Baseline value of CO content in exhaust smoke Exhaust smoke temperature reference value

[0081] Obtain real-time operating data of the unit:

[0082] The real-time operation data of the unit is collected through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com