Remote automatic control method for enamelling machine

An automatic control, enameling machine technology, applied in non-electric variable control, temperature control, control/regulation system and other directions, to achieve the effect of intuitive display, conducive to centralized control, accurate and timely control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further illustrate the method of the present invention, a preferred embodiment of the present invention will now be described in detail. However, the embodiment is only for illustration and explanation, and cannot be used to limit the scope of patent protection of the present invention.

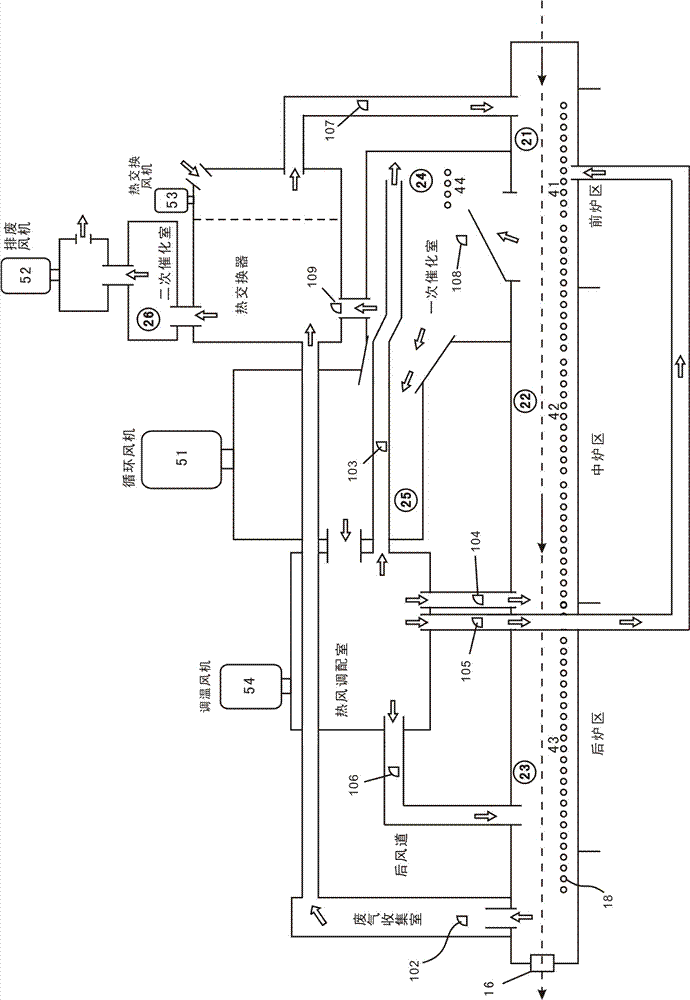

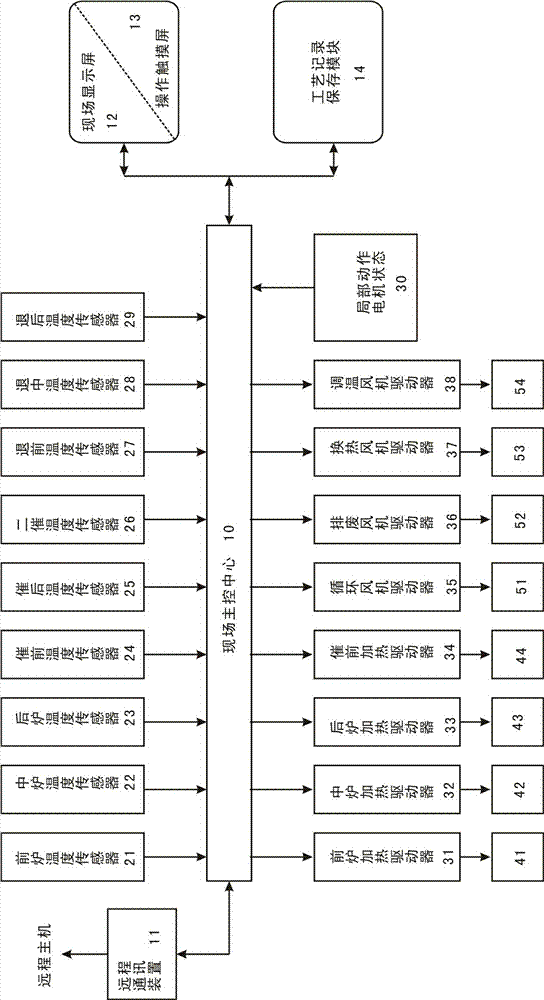

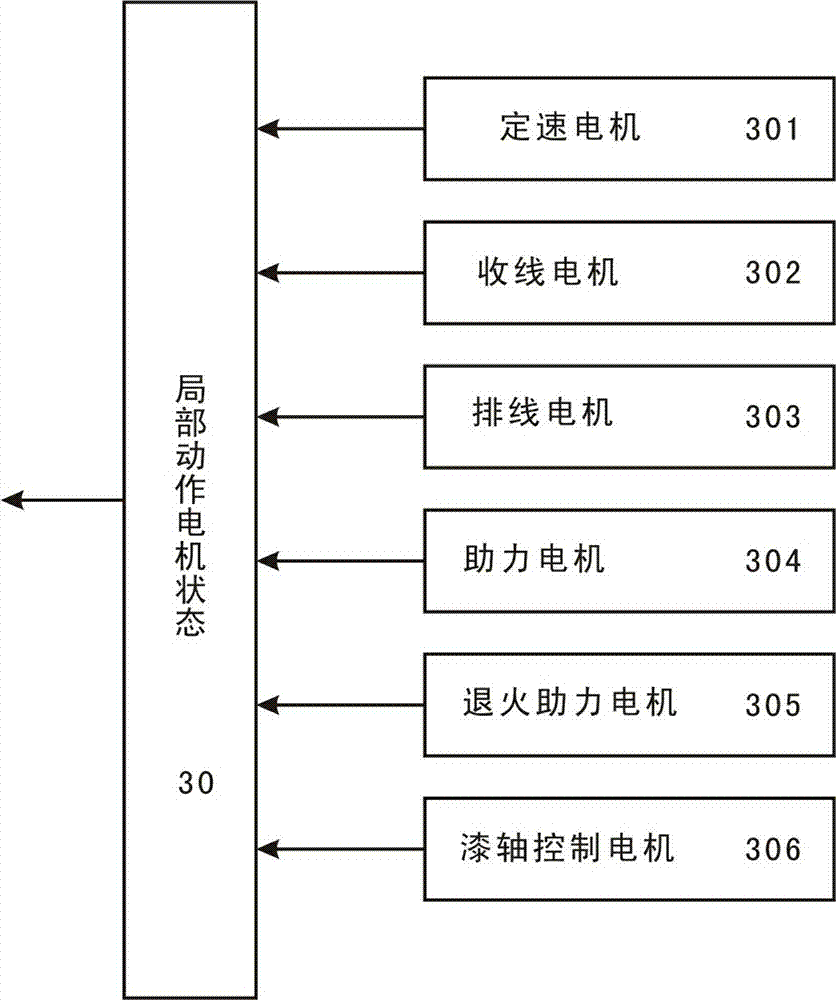

[0029] implemented as Figure 1 ~ Figure 4 Shown is a method for remote automatic control of an enamelling machine, said method comprising the following steps:

[0030] A, at first, a field master control center 10 is set at the production site, then a field display screen 12 and an operation touch screen 13 are set at the scene master control center 10; 11 is connected with the remote host by an industrial control bus; the process record saving module 14 is set in the on-site main control center 10 or the remote host;

[0031] B, then, fore furnace temperature sensor 21, middle furnace temperature sensor 22, rear furnace temperature sensor 23, temperature sensor 24 before...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com